unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

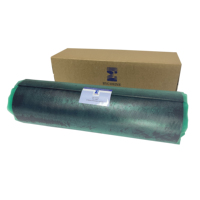

Whole Tire Recycling Rubber / Unvulcanized Recycled Rubber 12Mpa Tire Reclaimed Rubber for Tire Flap

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

unvulcanized rubber

Introduction to Unvulcanized Rubber

Unvulcanized rubber refers to natural or synthetic rubber that has not undergone the vulcanization process. This unique material retains its superior elasticity and flexibility, making it ideal for a wide range of applications in various industries. Understanding unvulcanized rubber is essential for manufacturers, engineers, and designers who are in quest of materials that provide enhanced performance characteristics, especially in applications where resiliency and adaptability are crucial.

Types of Unvulcanized Rubber

There are several types of unvulcanized rubber, each catering to specific needs and functionalities. The most common types include:

- Natural Unvulcanized Rubber: Sourced from rubber trees, it offers excellent tensile strength and resilience.

- Synthetic Unvulcanized Rubber: Manufactured from petroleum products, synthetic variants such as SBR and NR provide tailored features.

- Latex Rubber: A liquid form of unvulcanized rubber, latex is often used in gloves, balloons, and various other consumer goods.

- Butyl Rubber: Known for its airtight and resistant properties; it is commonly used in inner tubes and sealants.

Applications of Unvulcanized Rubber

The versatility of unvulcanized rubber allows it to be used in a multitude of applications across sectors. Here are some key areas where it is commonly utilized:

- Construction: Used for seals, gaskets, and vibration dampening applications owing to its superior sealing properties.

- Automotive Industry: Commonly found in the manufacturing of tires, sound insulation mats, and flexible parts that require high durability.

- Medical Equipment: An ideal choice for making gloves, medical devices, and other equipment due to its non-toxic and hypoallergenic nature.

- Footwear: Often incorporated into soles and insoles, delivering cushioning and flexibility in various types of footwear.

Features and Advantages of Unvulcanized Rubber

Choosing unvulcanized rubber comes with several benefits that can significantly enhance product performance. The key features include:

- High Elasticity: Maintains its stretchy properties and can be stretched repeatedly without losing shape.

- Flexibility: Able to conform to various shapes and sizes, making it ideal for applications requiring adaptability.

- Resistance to Aging: Offers better aging properties than vulcanized rubber, making it durable over time without hardening or cracking.

- Eco-Friendliness: Natural forms are biodegradable, providing an environmentally friendly alternative for sustainable product development.