used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

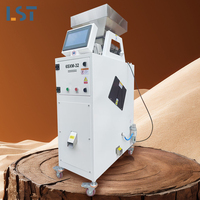

RealTech Whole Set Machine Small Rice Color Sorter Used Color Sorter China Manufacturer Color Sorter

used color sorter

used color sorter

used color sorter

4-6kw Oil Free Air Compressor for Mini Color Sorter Used in Combined Rice Mill/ Rice Sorting Machine

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

used color sorter

Types of used color sorters

A used color sorter is a machinery that sorts materials or products according to their colors. Normally, it is used for sorting food products like grains, vegetables, fruits, etc. Various types of used color sorters are available in the market to fulfill different industrial needs.

-

Optical Color Sorters:

They are the most common types of used color sorters. Optical sorters utilize camera systems and advanced image processing software to identify and sort objects based on their color variations. Once the unwanted materials are identified, the sorters separate them using air jets. Optical color sorters are widely used for sorting grains, legumes, seeds, etc.

-

RGB Color Sorters:

RGB color sorters are a specific type of optical sorter that relies on red, green, and blue (RGB) camera technology to detect color differences. These sorters can identify foreign materials and good products based on the color information captured by the RGB cameras. Like other optical sorters, they use air jets to remove undesired materials. The advantage of RGB color sorters is that they can be set up to recognize particular colors or color combinations, making them adaptable to various sorting needs.

-

Near-Infrared (NIR) Color Sorters:

NIR color sorters are used sorters that utilize near-infrared technology to identify materials based on their spectral properties. NIR sensors can detect different organic materials, such as plastics, fruits, and recyclables, based on their distinct NIR signatures. These signatures are then processed, and undesired materials are separated using air jets. NIR sorters are particularly useful for sorting tasks that involve differentiating materials with similar colors but distinct chemical compositions.

-

Multispectral Color Sorters:

Multispectral sorters are advanced sorting machines that combine information from multiple wavelengths. They are capable of offering more precise identifications and separations than traditional sorters since they collect data across a variety of spectral bands. Multispectral color sorters are adaptable to complex sorting tasks thanks to their capacity to identify a wide range of materials and colors.

-

X-Ray Color Sorters:

X-ray color sorters are specialized sorting machines that use X-ray technology to differentiate materials based on their internal composition. X-ray sensors can detect specific materials, densities, and shapes, allowing for the separation of unwanted objects based on their unique characteristics. X-ray color sorters find applications in industries such as mining, recycling, and food processing, where extracting contaminants or undesired materials e.g. bones from chicken products is critical.

Specifications and maintenance of used color sorters

Some typical specifications when buying a second-hand color sorter include the kind of food, capacity, precision, voltage, and measurement.

- Food: Common used color sorters for sale like rice or nut ones can often only sort their specific foods. Color sorters for grain food like corn or wheat sort differently because dust is a part of the food chain. Therefore, buyer needs are crucial here. Food sorting ones have food chutes designed for that specific food.

- Capacity: This refers to how much food the sorter can handle each hour. A sorter with a low capacity is better for smaller food producers, while one with a higher capacity suits large ones. For example, a rice sorter can sort roughly 1,100kg of rice an hour. Nuss sorters can handle 600kg to 3,500kg of nuts each hour.

- Precision: This refers to a machine's ability to precisely pick out unwanted food items like insects, stones, or underdeveloped grains. A used color sorter with high precision is better for companies that need their products to be 100% clean.

- Voltage: Most used color sorters are 220V. However, some are 110V, and others can be 3,000V. High-voltage machines are suitable for big industrial areas, while lower ones are better for small locations.

- Size: The sorter's physical size or dimensions are crucial for small places, which could be a rectangular sorter measuring 420*660*1,500mm. Big sorting facilities need far larger machines that can sort thousands of tons of food daily.

Proper maintenance of a used food sorter can help it function well for years. Daily, weekly, monthly, and quarterly upkeep is essential. Daily maintenance is to clean and lubricate all parts of the machine. It is crucial but simple. Weekly tasks are more complicated, such as checking all bolts and water pumps. Set water pump pressure between 0.2 and 0.4 Mpa. Monthly maintenance includes taking apart the hopper and funnel and cleaning them. A blower can assist in getting to hard-to-reach areas. The blower should have at least 2.5 hp to do a pest inspection and fuel the engine. Also, carry out a detailed examination of critical sorter parts. A simple battery can power the funnel fan. During the monthly check, the user should inspect the data analysis process to see how well the machine runs and any possible color sorter defects. Quarterly tasks include greasing all drive rollers and taking off belts to clean both sides.

Usage scenarios for used color sorters

Second-hand color sorters are widely used in industries where raw materials need to be sorted according to color. Farmers and food processing companies use used color sorters to separate high-quality, uniform-looking fruits and vegetables for sale and consumption. They can also be used to remove undesirable or potentially harmful colored contaminants.

Used color sorters are widely used in the textile industry to separate and grade differently colored fibers, yarns, and fabrics. They help maintain color consistency and quality in final textile products. Second-hand color sorters are commonly used in the recycling industry to sort various materials, such as plastics, Glass, and paper, based on color. They help enhance the quality of recycled materials and facilitate efficient processing.

Used color sorters are often employed in the wood processing industry to sort timber, veneers, and plywood based on color and quality. They assist in ensuring uniformity and aesthetics in woodworking projects. Used color sorters can be applied in the mining and mineral processing industries to separate valuable minerals and ores from unwanted colored materials or gangue, improving the purity and quality of mineral products.

Second-hand color sorters are used in online retail warehouses to quickly sort and categorize products based on color for efficient storage and retrieval. They can be used in agricultural research labs for experimental purposes but are not typically used at them. Education institutions may have second-hand sorters for educational purposes and hands-on training of students in material sorting technologies.

Choosing the right used color sorter

When it comes to choosing a used color sorting machine for sale, buyers need to take some critical things into account. Typically, the reason for buying a second-hand color sorter will have an impact on the qualities of the sorter that will need to be.

- Task Requirements: The type of product being sorted will have an impact on the choice of which color sorter to go for. For example, granular items like rice or sugar can be sorted using a different sorting mechanism than items with a more complex structure, like leafy vegetables or fruit. Therefore, sorters must be chosen based on the kind of food product that needs to be sorted and what kind of impurities or defects need to be identified and removed.

- Capacity & Speed: The capacity and speed of the sorter are critical, especially if a high throughput is needed. Determining the volume of food that needs to be sorted will help to identify the appropriate model that matches the sifting requirements. The latter also includes the desired accuracy and precision of sorting. Some color sorters offer advanced algorithms that can identify even the slightest defects and ensure the highest quality standards are met.

- Data Analytics: Many modern color sorters now offer data analysis capabilities. This allows farmers, packers, and anyone involved in processing food to monitor sorting patterns, yield percentages, and error rates. Users can then gather valuable information to improve their product quality and streamline their sorting process.

- Integration: It is essential to consider whether the sorter being purchased will integrate seamlessly with all the other machinery already in place. Whether it is a conveyer belt, packing system, or milling machine, the sorting machine should fit well with the rest of the production line, and this will enable smooth product flow and minimal downtime.

- Budget: Last but not least, the price of the used color sorter will be a factor when making this decision. Everyone knows that new machines cost a lot of money; therefore, it is essential to know what the second-hand machine is worth and what sort of color sorting technology can be afforded on a specific budget. Some sorters with advanced technology may come at a higher price.

Q&A

Q: How does a Color sorter machine works?

A: The working process of a color sorter is as follows:

-Firstly, the materials will be sent to the feeding system. Then, they will be dispersed into small pieces or a single layer of the material on the conveyor belt.

-Based on the signals sent by the sensors, if there are items that need to be sorted, the sorting mechanism will operate. It will subsequently blow air blasts to remove those items from the conveyor belt.

-Finally, the sorted materials will be collected into different bins or containers.

Q: What are the advantages of color sorting technology?

A: Color sorting technology provides several benefits. It can sort a variety of colors or shades, enhancing sorting accuracy. It also has automation capabilities, simplifying operations and boosting efficiency. Additionally, color sorting machines are adaptable, with adjustable parameters to meet distinct sorting needs. The durability and reliability of these machines ensure stable performance even under challenging working conditions, minimizing maintenance requirements and downtime.