used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

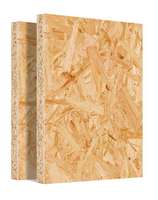

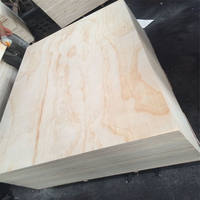

Plywood Sheet 4x8 Wood Grain Color Melamine Melamine Board 5 Types Furnitures Used Laminated Plywood

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

used plywood sheets

Types of Used Plywood Sheets

Used plywood sheets are panels made of thin layers of wood veneer glued together, with one or more used sheets of veneer on the surface. They are reused and repurposed plywood sheets that can be used for various projects depending on their condition. They come in different types and grades, which depend on their intended use. Here are some of the commonly used types:

- Structural plywood: This is also known as construction or formwork plywood. It is used for structural applications such as flooring, bracing, roofing, and subflooring. This plywood is strong and durable, able to withstand heavy loads and moisture.

- Decorative plywood: Also known as fancy or interior plywood. It is used for cabinets, walls, and furniture. It features a smooth surface with decorative grain patterns. This type of plywood is more expensive than other types because it is made from high-quality veneer.

- Marine plywood: This type of plywood is designed for areas with high moisture content and water exposure. It is used to build boats, docks, and other structures that are exposed to water. Marine plywood is durable, weather-resistant, and water-proof.

- Flexible plywood: This is also known as bendable or formable plywood. It is used where flexible surfaces are needed, such as curved walls and furniture. It is made from thin layers of wood veneer that can bend and curve.

- Compostable plywood: This type of plywood is made from sustainable materials and is fully compostable. It is designed for use in temporary structures and applications where environmental impact needs to be minimized. Compostable plywood is manufactured using bio-based adhesives and has no synthetic coatings.

- Fire-rated plywood: This type of plywood is treated with fire-retardant chemicals to improve its resistance to burning. It is used in applications where building codes require fire-rated materials, such as in commercial and residential construction for walls and ceilings.

- Soundproof plywood: This plywood is designed to reduce noise transmission. It is heavy and dense, which helps to block sound waves. Soundproof plywood is used in studios, theaters, and other places where noise needs to be controlled.

- Pressure-treated plywood: This type of plywood is treated with preservatives under high pressure to prevent rot, decay, and insect damage. It is commonly used in outdoor projects such as decks, fences, and garden structures where it will be exposed to moisture and ground contact.

Function and feature of used plywood sheets

The function of used plywood sheets is similar to that of new sheets. They can be used in the construction of buildings, subfloors, decks, and walls. Used plywood is also used to make furniture and cabinets. It can also be used for other projects in the home, such as creating a shelf, fixing a fence, or even fixing a chair.

Features of used plywood sheets:

- Layers: Plywood, whether used or new, has layers. These layers are called veneers. The more the layers, the stronger the plywood. These layers are bonded using adhesive. The layers run in different directions, which makes the plywood sheet stable.

- Grain: The grain of the plywood determines its finish. The grain can be straight, curly, or wavy. Straight grain is the most common type of grain found on plywood.

- Thickness: Used plywood comes in different thicknesses. The thickness ranges from 1/4 to 1 inch. The thicker the plywood, the stronger it is. Thicker plywood is also used for heavy-duty work, while thinner plywood is used for lighter work.

- Face veneer: This is the top layer of the plywood. It affects the appearance of the plywood and, as a result, its use. It can be an expensive veneer, a decorative veneer, or a core veneer.

- Back veneer: This is the opposite side of the face veneer. It is also called the back face. It can be sanded, or it can have knots and stains. Back veneers are less expensive than face veneers.

- Core: The core of the plywood is the middle part. It determines the strength and thickness of the plywood. There are three different types of cores: solid core, honeycomb core, and flexible core.

- Glue: The glue in the plywood makes it waterproof and determines its grade. There are different types of glue, such as MR, which means moisture-resistant glue. This glue is used for interior-grade plywood. Another type is PF glue. This glue is used for exterior-grade plywood and is waterproof.

Scenarios of Used Plywood Sheets

Used plywood sheets, depending on their condition and quality, can have a variety of applications. Here are some common usage scenarios:

-

DIY Projects

Used plywood is often sought after by hobbyists and DIY enthusiasts for small-scale projects. It is a cost-effective option for creating storage boxes, picture frames, birdhouses, and other small items.

-

Temporary Structures

Used plywood is frequently utilized to build temporary structures in events and concerts. It can be used to make stage platforms, walkways, and barriers that can be easily assembled and disassembled as required.

-

Repairs and Patch Jobs

Leftover pieces of plywood from previous projects can be used to make repairs. These leftover pieces can be used to patch up holes in walls, fix broken furniture, or repair decks and patios, saving the need to buy new materials.

-

Sheathing

When building or retrofitting structures, used plywood can be employed as sheathing for walls, roofs, and floors. This adds structural support and stability and is especially useful in wind-prone and seismic areas.

-

Backdrops and Displays

In exhibitions, trade shows, and presentations, used plywood can be employed to make backdrops, display boards, and signs. It is easy to customize and paint, offering a more stable alternative to cardboard.

-

Garden Projects

Used plywood can be utilized in various outdoor projects around the garden or yard. It can be transformed into raised garden beds, compost bins, or plant shelving. Additionally, larger pieces can be employed to make simple outdoor furniture like benches and tables.

-

Underlayment

Used plywood can function as an underlayment for flooring in low-traffic areas. It provides a smooth base for carpet, linoleum, or tile flooring, helping to reduce costs when renovating a room.

-

Wall Art and Decor

Creative individuals can use small pieces of used plywood to make wall art and decor projects. This can include painted or etched designs on plywood panels or assemblages of recycled materials mounted on plywood bases.

-

Storage Solutions

Used plywood can be employed to make simple storage solutions like shelves, drawers, and cabinets, especially in garages or basements where appearance is less important than functionality.

How to choose used plywood sheets

-

Assess the Plywood's Condition

Inspect the used plywood for any visible damage, rot, or warping. Select sheets that are as straight and flat as possible and have no significant cracks or splits. Check the edges and corners to ensure they are not chipped or damaged. Look for any signs of water damage or staining on the surface. Water damage can cause the plywood to become weak and brittle.

-

Evaluate the Grade and Type

Determine the intended use to select the appropriate grade and type of plywood. Higher-grade plywood with fewer knots and blemishes is suitable for visible surfaces, while lower-grade plywood is acceptable for structural applications. Consider the type of plywood, such as softwood, hardwood, exterior, or interior, depending on the specific requirements.

-

Check the Thickness and Size

Ensure that the used plywood sheets are of the required thickness and size. Used plywood can come in different thicknesses, and choosing one that meets the project needs is essential. Also, consider the standard sizes, such as 4x8 feet sheets, to ensure they will fit when purchased.

-

Examine the Surface

Check the surface of the used plywood for any damage, warping, or irregularities. A smooth and even surface is essential for finishes that require it. Additionally, ensure the surface is clean and free of any debris or contaminants that could affect the quality of the finish.

-

Consider the Price

When buying used plywood in bulk, it is vital to consider pricing to stay within budget. Compare the prices of different used plywood sheets while considering their quality and condition. A lower price may be tempting, but it could indicate poorer quality or more damage, leading to higher costs in the long run.

Used Plywood Sheets Q&A

Q1: What are the most common sizes of used plywood sheets?

A1: The most common sizes are 4 feet by 8 feet. These dimensions are used in many construction projects. Other sizes are also available. Some retailers offer custom-cut sizes to reduce waste and meet specific project requirements.

Q2: How can someone determine the grade of a used plywood sheet?

A2: It is possible to check the grade by looking at the markings on the panel. These markings provide information about the plywood's species, quality, and characteristics. Even though the markings may be difficult to find, they are usually located on one of the panel's faces or edges. In some cases, the markings may be found on the back of the panel.

Q3: Can used plywood be recycled?

A3: Yes, used plywood can be recycled, but the process may be more complicated than that of other wood products. Plywood's adhesive layers, which give it strength and durability, can make recycling difficult. These adhesives may contain chemicals that complicate the recycling process. However, some recycling facilities can process used plywood, extracting valuable wood chips or producing biofuel. It is always advisable to check local recycling facilities to determine their capabilities.

Q4: How to store used plywood to prevent damage?

A4: To store used plywood properly, it should be kept in a dry, well-ventilated area. It should be elevated off the ground using pallets or架子to防止潮湿。确保空气流动以防止霉菌生长和翘曲。避免将其暴露于直接阳光或极端天气条件,因为这会造成损坏。保持堅固的平坦,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穩定,穎,並使用緊固件防止任何應力或損壞。

Q5: What are the signs of water damage on used plywood?

A5: Signs of water damage include discoloration, such as yellow or brown stains, and warping or bending of the surface. It may also show signs of mold or mildew growth. The plywood may feel soft or spongy to the touch. In some cases, the adhesive used in the plywood may break down, causing delamination.