vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

XXL Vacuum Butt Lift Cups Buttuck Vacuum Butt Lifting Vacuum Cupping Therapy Machine with Large Cups

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

vacuum machine

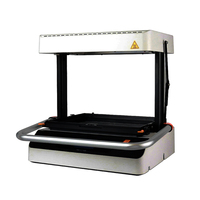

Types of vacuum machines

A vacuum machine is an essential tool in food packaging. It comes in different types, each suitable for different food packaging needs. They include the following:

- Chamber vacuum sealers

Chamber vacuum sealers are among the most common types of vacuum sealers. They come with a small chamber that the packaging bag sits into. The machine then removes the air from the chamber and bag. It does this by creating a vacuum that sucks the air out of the bag, sealing the bag before it refills the chamber with air. Chamber vacuum sealers are perfect for bulky items and high-volume sealing. They're also suitable for liquid items. However, they take up more counter space than other vacuum sealer types.

- Piston pump vacuum sealers

Piston pump vacuum sealers work by drawing out air from the bag with a piston or motorized pump. This is done while sealing the bag simultaneously. Piston pump vacuum sealers are more affordable and compact than the chamber type. They are ideal for home kitchen use and small-scale packaging needs. However, they can be slower than other vacuum sealer types.

- External vacuum sealers

External vacuum sealers work by having the open end of the bag placed on the sealing strip. The machine then sucks air out of the bag and seals it. They are smaller and can be more portable than other vacuum sealer types. They are suitable for individuals who need to package food on the go. However, external vacuum sealers are not suitable for liquids. Also, the sealing process takes longer than other sealer types.

- Gas-flush vacuum sealers

Gas-flush vacuum sealers work by replacing the air inside the bag with a mix of gases. This helps prevent the food from spoiling quickly. They are more suitable for food items prone to spoilage. Gas-flush vacuum sealers are perfect for commercial use. However, they are more expensive than standard vacuum sealers.

- Double-chamber sealers

Double-chamber sealers have two chambers that can be used simultaneously. They are ideal for high-volume packaging needs. Also, they can be more efficient than single-chamber sealers. However, they take up more floor space.

Specifications and maintenance of vacuum machines

Because there are different types of vacuum seal machines for food with different specifications, it's best to focus on general specifications rather than specific ones.

- Seal Width: The seal width is how wide the vacuum sealer can make a seal. It's important for ensuring a secure seal between the bag’s sides. For most vacuum sealers, the seal width ranges from two to three millimeters. Larger seal widths might be more suitable for those needing a stronger seal.

- Vacuum Pressure: Vacuum pressure is how much air can be removed from the bag. It’s usually measured in inches of mercury (inHg) and can range from 20 inHg to 30 inHg. Higher vacuum pressure often means more air will be removed from the bag, which helps to maximize freshness and storage time.

- Pump Type: Most vacuum sealers use a piston or rotary pump. Rotary pumps are generally faster and more durable than piston pumps. The sealing bar is the part of the vacuum sealer that creates a seal by applying heat and pressure to the open end of the bag. It’s important to choose a vacuum sealer with a good-quality sealing bar to ensure a strong and reliable seal.

With the right care and maintenance, a vacuum sealer machine can last for years. First and foremost, read the manufacturer's instructions thoroughly. Manufacturers often include specific cleaning and maintenance instructions for their machines, so it's important to follow their guidelines closely. Make sure the sealer is unplugged before cleaning it to avoid the risk of electric shock. Use a damp cloth to wipe the exterior of the sealer and the vacuum channel. Avoid using abrasive materials or harsh chemicals, as they can damage the sealer. Some sealers have removable drip trays or dishwasher-safe parts. Check the user manual for more information about cleaning these parts.

It's also important to keep the sealer dust-free. When not in use, store it in a clean, dry place away from dust and debris. Regularly inspect the sealer for signs of damage or wear, such as frayed cords or loose parts. If any damage is found, stop using the sealer and contact the manufacturer for assistance. Performing basic maintenance on a vacuum sealer can help it last longer and provide reliable performance.

Scenarios of vacuum machines

Catering and restaurant businesses use commercial vacuum machines to preserve food, reduce waste and maintain food quality. When used for meal prepping, they help maintain the taste and quality of the food for customers after several days or weeks. Restaurants can also use these machines to marinate foods quickly, infusing flavors in a fraction of the time it would take to marinate them naturally.

Commercial-grade vacuum machines are used in the food industry to package various perishable items such as meat, cheese, and vegetables. The vacuum-sealed bags help to extend the shelf life of these items and reduce spoilage and waste. They are also used in the production of processed foods like snacks and baked goods. Vacuum machines can remove excess air from the packaging, creating a tamper-proof seal that enhances product freshness and safety.

In the pharmaceutical industry, vacuum packaging machines are used to package and seal medications, supplements, and other health products. The vacuum-sealed packaging helps to maintain the potency and effectiveness of the products by protecting them from moisture, oxygen, and other contaminants. They are also used to package and preserve historical artifacts, important documents, and valuable collectibles. The vacuum sealing process creates an airtight barrier that protects these items from environmental degradation and damage.

Household vacuum machines are used to package and store food at home. Users can also use them to create pre-portioned meals for quick and easy cooking. They can also be used to preserve leftovers and bulk purchases, reducing food waste. Some people also use these machines to store non-food items such as clothing, documents, and electronics. Vacuum-sealed storage can help protect these items from moisture, dust, and pests.

In the medical field, vacuum machines are used to create a vacuum in wound drainage systems and suction catheters. They help to remove excess fluids and maintain a clean and sterile environment to aid in the healing process.

How to Choose Vacuum Machines

When selecting a vacuum packaging machine for sale, there are several things to consider. Firstly, it is crucial to evaluate the type of vacuum machine and the application it is intended for. For example, an industrial food vacuum sealer would not be suitable for use in a home kitchen. If buying the machine for use in a commercial setting, it is essential to ensure that the vacuum machine has the capacity and features that will satisfy the business's needs.

It is also important to ensure that the machine chosen is compatible with the type of bags that will be used with it. Not all vacuum sealers can use any type of vacuum sealer bag. The dimensions of the machine itself should also be taken into account. If it will be placed on a countertop, its size and weight should be suitable for the space available. If it will be used for packaging food, the durability and type of material used to construct the machine should be considered. The machine should have the ability to withstand moist conditions and regular exposure to water and cleaning chemicals.

When looking for a machine that will be used frequently, it is essential to consider the warranty and build quality. The machine should be made of sturdy, long-lasting materials and come with a warranty that covers any potential issues. The cost is also a significant factor when selecting a vacuum machine. The price of the machine will depend on its features, design, quality, and brand. It is important to research and compare different products and their prices to determine which is the best value for the budget.

Finally, one should consider the machine's power requirements. Some models are powered entirely by hand, and some require a gas supply. The power requirements and compatibility with the existing power supply should be checked.

Q&A

Q1 What is the difference between single and double-chamber vacuum machines?

A1 Single chamber vacuum machine processes one pack at a time, while double-chamber vacuum machines have two chambers that can run simultaneously or independently, increasing output.

Q2 What are the benefits of using a vacuum machine?

A2 It extends the shelf life of products by removing air and reducing bacterial growth and spoilage. In addition, it enhances flavor and quality by preserving freshness and nutrition.

Q3 What type of bags should be used in a vacuum sealer machine?

A3 Vacuum sealer bags are specially designed for machine use. They are constructed of multi-layer material that can withstand the vacuum and heat sealing process.

Q4 Can a vacuum machine be used for liquids?

A4 Yes, it is possible. However, some vacuum sealers are specifically designed for liquid packaging and have special features to prevent liquids from being sucked into the machine.

Q5 Is it safe to use a vacuum sealer machine to store food?

A5 Yes, vacuum sealers are safe for food storage. They can help reduce the risk of contamination and spoilage.