waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

waterproof foam board

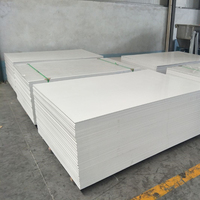

Waterproof foam board serves a multitude of purposes in various industries. Crafted from a water-resistant material, it can withstand damp environments and direct contact with liquid. It is ideal for outdoor advertising and provides a sturdy base for signages, banners, and displays. Its resilience against moisture makes it a preferred choice for bathroom and kitchen decor. This material also proves beneficial in the construction sector. Utilized as insulation, it enhances energy efficiency by reducing heat loss. Its waterproof nature prevents damage from dampness and mold growth, ensuring the longevity of structures. A versatile product, it finds use in the packaging industry, too. The lightweight yet sturdy nature of the board protects goods from damage during transportation. In art and craft projects, it offers a durable and resilient canvas. Easy to cut and shape, it allows for creative flexibility. Available in various thicknesses and sizes, it caters to diverse requirements. A durable, adaptable, cost-effective solution, waterproof foam board is essential across multiple sectors.

Types of waterproof foam boards

Waterproof foam core board and insulation board are two primary types prevalent in the market. While the core board is often used for signage, exhibits, and photo mounting due to its rigidity and lightweight properties, the insulation board serves as an effective thermal insulator and water-resistant barrier in building constructions. Furthermore, waterproof foam board for showers and kerdi foam board are specially designed for high-moisture areas such as bathrooms, providing a mold-resistant substrate for tiles and wall finishes. Additionally, a type of foam board known as Phenolic foam offers exceptional fire resistance and low smoke emissions, making it ideal for use in buildings where fire safety is a top priority. Lastly, Flexible foam boards provide a waterproof solution for curved surfaces and complex designs, offering architects and builders greater flexibility in their projects. Each type of waterproof foam board has unique properties, making it suitable for various applications in construction and beyond.

Applications and features of waterproof foam boards

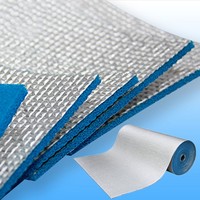

The applications of waterproof foam boards are vast and varied. In the construction sector, foam waterproof backer board is frequently employed as a substrate for tiling, particularly in wet areas such as bathrooms and kitchens. Waterproof foam board insulation is another essential use, offering energy efficiency to homes and buildings by creating a barrier against moisture and temperature changes. Furthermore, the waterproof insulation board for walls ensures that wall cavities remain dry, preventing the growth of mold and mildew. Likewise, their use in floating docks and pontoons showcases their adaptability. Hence, waterproof foam boards are used in many applications due to their durability, water resistance, and versatility.

The features that make waterproof foam boards so widely used include their lightweight nature, ease of cutting and shaping, and moisture resistance, an essential attribute for any material used in damp environments. Waterproof styrofoam sheets are also available for projects requiring buoyancy, like creating floating docks or a core material in marine applications. High strength and lightweight nature make these boards easy to handle and install. Despite their light, these boards offer a robust structure. The rigidity ensures that the boards do not bend or break under pressure. Insulation properties are another notable feature. Waterproof foam boards provide excellent thermal insulation. This feature makes them better for use in construction, especially in areas where temperature regulation is critical.