waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

waterproof insulation board

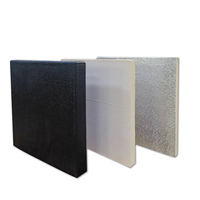

Types of waterproof insulation board

A waterproof insulation board is a type of insulation material that combines waterproofing and insulation properties. It is designed to provide thermal insulation while also preventing water ingress or moisture. These boards are commonly used in construction and building projects where both insulation and waterproofing are required, such as in roofs, walls, foundations, and areas prone to moisture, like bathrooms and kitchens.

Waterproof insulation boards come in different types, including:

-

Foam boards: These boards are also called foam insulation panels. They are made of rigid foam plastic. This includes polystyrene, polyisocyanurate/ polyurethane foam, and extruded polystyrene foam. Waterproof foam boards are lightweight and have high R-values. They are used in various applications, including foundation walls, under slab insulation, unvented roofs, and exterior insulated finishing systems. Waterproof foam boards are popular because they offer insulation at a lower cost.

-

Gypsum boards: Gypsum waterproof insulation boards are made of gypsum plaster. Waterproof gypsum boards have paper or fiberglass mat facing. They are used to provide insulation and resistance to moisture. Gypsum boards are non-combustible and have a smooth surface that is easy to finish. They are commonly used in areas where insulation and moisture resistance are required, such as bathrooms, kitchens, and exterior walls.

-

Wood boards: These are made from oriented strand board (OSB) or wafer board. They have strands of wood bonded together with adhesives in an oriented strand board. Waterproof wood boards offer good insulation value and structural support. They are used in exterior walls, roofs, and subfloors. Waterproof wood boards are popular because they are environmentally friendly and have good moisture resistance when properly sealed.

-

Mineral wool boards: These boards are made from rock, stone, or slag. It is melted and spun into fibers. Waterproof mineral wool boards are then formed into rigid boards. They are fire-resistant, water-repellent, and provide good acoustic insulation. Waterproof mineral wool boards are used in walls, roofs, and areas where thermal insulation and fire resistance are required. They are popular because they are sustainable and offer high thermal performance.

-

Reflective or Radiant Barrier Insulation: These boards have a reflective surface, such as aluminum foil, that reflects radiant heat away from the living space. They are used in hot climates to keep buildings cool and reduce air conditioning costs.

Function and Feature of Waterproof Insulation Board

Waterproof insulation boards are used in construction to provide thermal insulation, support structural integrity, and protect against moisture. Their features include:

-

Thermal Insulation

Thermal insulation waterproof board is used in construction to keep buildings warm in winter and cool in summer. They reflect heat away from the building during summer while, in winter, they keep heat inside. This happens because heat moves from a warmer place to a cooler area.

-

Moisture Resistance

Waterproof insulation boards are made with materials that cannot be broken down or damaged by water. They have a solid structure, so water cannot get through (known as water permeability). Examples of waterproof insulation boards include polyisocyanurate (PIR), polyurethane (PUR) and expanded polystyrene (EPS) insulation boards.

-

Lightweight

Insulation board is light, making it easy to carry and work with when putting buildings together. Being light means it does not add extra weight to the structure being built.

-

Compressive Strength

Waterproof insulation boards can withstand a lot of pressure without breaking. They can bear the weight of hands walking on them without damage. This makes them excellent for use in roofs, decks, and areas where people or things can walk over.

-

Ease of Handling and Installation

Waterproof insulation boards are simple to work with. They can be easily cut to the correct size and shape needed for different projects using standard tools. Their light weight also makes them simple to move and position.

-

Durability

These boards are made to last a long time without being damaged. They can withstand daily wear and tear in buildings without showing signs of aging or deterioration. Once the board is installed, it needs little maintenance over its lifespan. The waterproof and moisture-resistant properties help keep it in good condition.

-

Versatility

Waterproof insulation boards can be used in different parts of buildings like walls, roofs, and floors. They work well for any insulation project that needs waterproofing.

Scenarios of waterproof insulation board

-

Construction and Renovation Projects:

Waterproof insulation boards are commonly used in construction and renovation projects, such as:

Residential and commercial buildings: These boards are used in foundations, exterior walls, roofs, and under slabs to provide insulation, waterproofing, and a vapor barrier.

Basement finishing: Waterproof insulation boards are used to insulate and finish basement walls, providing a moisture-resistant and energy-efficient living space.

Remodeling projects in areas prone to moisture: These include kitchens, bathrooms, and laundry rooms where waterproof insulation boards are installed on walls and ceilings to prevent mold and mildew growth.

-

Manufacturing and Industrial Applications:

Waterproof insulation boards are used in various manufacturing and industrial settings, such as:

Cold storage facilities and refrigerated trucks: Insulation boards are critical in maintaining low temperatures and preventing condensation and frost buildup in these applications.

Manufacturing plants: These include food processing, pharmaceuticals, and chemicals where moisture control and temperature regulation are essential for product safety and quality.

-

Commercial and Hospitality Projects:

These boards are popular in commercial and hospitality settings due to their performance and durability, including:

Hotels and resorts: Waterproof insulation boards are used in guest rooms, bathrooms, and spa facilities to provide insulation and waterproofing.

Restaurants and catering facilities: These include walk-in coolers and freezers, prep areas, and dishwashing rooms that require moisture-resistant insulation.

Retail stores and shopping malls: Waterproof insulation boards are used in storage areas, walk-in refrigerators, and freezers.

-

Infrastructure and Public Works Projects:

Waterproof insulation boards are used in various infrastructure and public works projects due to their durability and performance, such as:

Tunnels and underground structures: Insulation boards are used to provide waterproofing and insulation in tunnels, subways, and underground parking garages.

Bridges and overpasses: These boards are used in the construction and maintenance of bridges and overpasses to protect against moisture and temperature variations.

Infrastructure projects: Waterproof insulation boards are used in retaining walls, drainage systems, and other infrastructure projects requiring waterproofing and insulation.

How to choose waterproof insulation board

When choosing a waterproof thermal insulation board for sale, it is important to consider a few factors. The factors ensure that one gets a board that is suitable for a particular project. Here are some of them:

-

Type of insulation board

Waterproof insulation boards come in different types. Each type has its unique insulation properties. These can be tailored to meet different needs. Hence, it is important to consider the type that best suits the intended purpose.

-

Thickness and R-value

Waterproof insulation boards come in different thicknesses. In most cases, the thickness affects the R-value. The R-value is a measure of thermal resistance. It is important to choose a board with a high R-value. A board with a high R-value offers better insulation and improves energy efficiency.

-

Moisture resistance

The primary purpose of a waterproof insulation board is to provide moisture resistance. Therefore, it protects against water damage. Consider the level of moisture resistance required. This depends on the area where the insulation board will be installed. For instance, areas with high humidity or direct water flow require a board with high moisture resistance.

-

Environmental impact

Insulation boards are manufactured with different materials. Some materials are environmentally friendly. Examples include recycled content and bio-based materials. Choosing a waterproof insulation board that is environmentally friendly goes a long way in reducing ecological impact.

-

Compatibility

The waterproof insulation board is installed in various construction setups. For example, it can be installed on roofs, walls and floors. Therefore, it is important to consider its compatibility with other construction materials. Such as framing systems and exterior cladding. This ensures a seamless installation process and optimizes performance.

-

Cost

Waterproof insulation boards come at different price points. The prices depend on the brand, type and place of purchase. It is important to consider the cost when choosing an insulation board. However, don't compromise on quality for the price. This is because a cheap board won't provide the necessary waterproofing and insulation.

waterproof insulation board Q & A

Q1: Is it necessary to use a waterproof insulation board for all construction projects?

A1: It depends on the project. If the construction is in a place that is not wet or waterproof insulation is not needed. However, boards are generally recommended for most construction projects since they provide added benefits like durability and temperature regulation.

Q2: Are waterproof insulation boards eco-friendly?

A2: Waterproof insulation boards are manufactured using different materials. Some boards are eco-friendly, and others are not. Waterproof insulation boards made with recycled materials are eco-friendly. Waterproof insulation boards made with polystyrene are not recycled are not eco-friendly.

Q3: What are the signs that a waterproof insulation board has been damaged?

A3: The first sign is visible wear and tear. This can be seen as water stains, mold growth, or mildew. Another sign is the structural integrity of the board. If the board is bent, warped, or soft, it is damaged. Change in shape or touch the board, and if it feels wet or damp, it is damaged.

Q4: Can waterproof insulation boards be repaired instead of replaced?

A4: In most cases, it is recommended to replace the board instead of repairing it. This is because repairs can create weak spots that compromise the insulation. However, in some cases, professionals can repair the board using patches and sealants. Waterproof insulation boards need expert knowledge, and homeowners should not attempt it.

Q5: Are waterproof insulation boards fire-resistant?

A5: Some waterproof insulation boards are fire resistant, and others are not. Manufacturers add fire-resistant chemicals during the manufacturing process to the boards that are fire resistant.

Popularity Trends

The keyword "waterproof insulation board" has shown notable fluctuations in web search volume over the past year, with an average monthly web search volume of 260. Over the last three months, there has been a significant increase of 86%, while the year-on-year change stands at 22%. Notably, search interest peaked in November 2024 with 390 web searches, contrasting sharply with the lowest point in March 2024 at 140 web searches.

Analyzing the search data month-by-month reveals a pattern of fluctuation that could be attributed to seasonal demand. Starting from December 2023 with 320 web searches, interest dipped in the early months of 2024 before gradually climbing back up. The peak in November 2024 suggests a seasonal increase in demand, likely influenced by colder weather when insulation becomes a critical consideration for both homeowners and construction projects.

These trends indicate a strong seasonal component to the web search volume for "waterproof insulation board," with spikes during colder months, possibly due to increased construction activities or renovations aimed at improving home insulation against winter conditions. This pattern highlights the importance of seasonal marketing strategies for businesses in the construction and real estate sector dealing with such products.