wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

wooden sheet

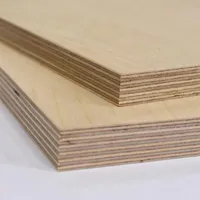

Types of Wooden Sheets

Wooden sheets, also known as plywood, are thin layers of wood veneer that are glued together to form a single sheet. These sheets are commonly used in making furniture, cabinets, and other woodworking projects. There are different types of wooden sheets available in the market. Here are some of them:

- Softwood Plywood

This type of wooden sheet is made from softwood trees like fir, pine, or cedar. The wood veneer is usually coated with a thin layer of plastic to protect it from water damage. Softwood plywood is popular for making exterior and interior projects like subfloors, roof decking, and furniture. Softwood plywood is further classified into different grades, including A, B, C, and D. The A grade is the highest quality and has no visible defects, while the D grade has many defects.

- Hardwood Plywood

Hardwood plywood is made from hardwood trees like oak, birch, or maple. It is considered a high-quality wooden sheet because it has a smooth finish and a strong structure. The wood veneer is usually glued together with waterproof glue to make it more durable. Hardwood plywood is used in making high-end furniture and cabinets. It is also used in making sports equipment like skateboards and snowboards.

- Veneer Core Plywood

Veneer wood sheets are a type of wooden sheet that is made from thin wood veneers. The wood veneers are glued together with a strong adhesive to form a single sheet. This type of plywood is lightweight and easy to work with. It is used in making curved furniture and boat hulls.

- Particleboard Core Plywood

This type of plywood has a core made of wood particles and a veneer finish. The wood particles are combined with resin and then pressed into a solid sheet. The sheet is then coated with a thin wood veneer to give it a smooth finish. Particleboard core plywood is commonly used in making cabinets, shelves, and furniture.

- Fiberboard Core Plywood

This type of plywood has a core made of wood fibers. The fibers are combined with adhesive and then compressed into a solid sheet. The sheet is then coated with a wood veneer finish. Fiberboard core plywood is durable and has a smooth finish. It is commonly used in making doors and high-end furniture.

Functions and Features of Wooden Sheets

- Function

Privacy: Wood is a material that is very useful in construction. It is used to build houses, furniture, tools, and many other things. The wooden sheet is a kind of wood that is used in construction to build walls, ceilings, and floors. It is also used to make furniture, such as cabinets, wardrobes, and bookshelves. One of the functions of wooden sheets is to provide privacy. It can be used to build walls that separate different rooms in a house or office.

Sound and Heat Insulation: Another function of a wooden sheet is that it can absorb sound and heat. This function is important when constructing a building. Wooden sheets are used in building ceilings and walls to absorb sound and prevent noise from entering a room. It also prevents the sound from inside the room from disturbing people outside. Wooden sheets are also used to build walls and ceilings that can prevent heat from entering a room. This helps to keep the room cool and reduces the cost of air conditioning.

Moisture Absorption: One of the functions of a wooden sheet is that it can absorb moisture. Wooden sheets are used for floors that can absorb water and prevent it from staying on the floor. This is important because when water stays on the floor, it can cause the floor to be slippery and dangerous. Wooden sheets are also used to make cabinets and wardrobes that can absorb moisture. This prevents the cabinet and wardrobe from growing mold and fungi.

- Features

Durability: One of the features of wooden sheets is that it is durable. This means that it can last for a long time without getting spoiled. Wooden sheets are made from different types of wood, and they can last for many years without getting damaged. Wooden sheets do not rot or decay as fast as other materials. They are also resistant to termites and other insects that destroy wood.

Versatility: A wooden sheet can be used in different ways. It is a versatile material that can be used for different purposes. Wooden sheets are available in different sizes, thicknesses, and finishes. This allows users to choose the one that is best for their project. For example, thin wooden sheets can be used for crafts and art, while thick ones can be used for building walls and floors.

Appearance: Wooden sheets are also popular because they look beautiful. They have a natural appearance that makes them a good choice for furniture and decorative items. Wooden sheets come in different colors, patterns, and textures, which add beauty to any space where they are used.

Scenarios of wooden sheet

- Construction and Building:

Builders and contractors utilize wood panels in framing and sheathing for residential and commercial projects. This is because it is a durable and cost-effective building material. It is also used for roofing because it is a good insulator and can withstand different weather conditions.

- Interior Design:

Interior designers and architects use wood sheets to create a warm, inviting atmosphere. It can be used for walls, ceilings, and floors. Wood panels are used for furniture and fittings. It is also used for design elements like cladding and wainscoting. All these help to create a beautiful and cohesive design.

- DIY and Crafts:

Craftsmen and hobbyists use wood panels for a variety of DIY and crafting projects. It can be used to build shelves, tables, and storage units. It is also used to create decorative items like signs and picture frames. Wood sheets can also be used to make gifts and personalized items. It is also used to build birdhouses and playhouses for children.

- Transportation:

Wood sheets are used in various transportation industries. For example, in the shipping industry, it is used to build shipping containers. It is also used to build trailers for trucks and other vehicles. Wood panels are used in the airline industry to construct airplane parts and interiors. It is also used in the automotive industry to make caravans and other vehicles.

- Soundproofing and Insulation:

Wood panels are great for soundproofing and insulation. It is used to make acoustic panels that block or absorb sound in spaces like recording studios and theaters. It is also used to create barriers that reduce noise pollution in residential and commercial areas. In terms of insulation, wood panels are used to build walls, roofs, and floors that keep spaces warm in cold weather.

How to choose wooden sheets

When purchasing wooden sheets for resale, buyers should consider the following factors:

- Wood type: Different wood types have unique characteristics that affect end-use. For instance, hardwoods are denser and more durable than softwoods. Therefore, they are suitable for furniture, cabinets, flooring, and construction projects that require strength and resilience. On the other hand, softwoods are easy to work with, making them ideal for DIY projects, underlayment, and crafting. Due to their attractive grain patterns and natural color variations, hardwoods are commonly used for decorative applications such as wall paneling and beams.

- Sheet thickness: Wood sheets are available in various thicknesses measured in inches, millimeters, or centimeters. They can range from thinnest wood sheets less than 1 mm thick to solid wood boards several inches thick. The thickness of the wooden sheet is an important consideration since it determines the weight and strength of the final product. Thicker sheets are more stable and durable, making them suitable for load-bearing applications such as cabinetry, furniture, and flooring. Thin sheets are flexible and ideal for curved surfaces, marquetry, and veneering.

- Grain and appearance: Different wood species have unique grain patterns, colors, and textures. It is important to choose a wood species that complements the overall design and style of the final application. For example, straight-grained woods such as maple and oak provide a clean and uniform appearance, ideal for modern and contemporary designs. In contrast, woods with pronounced grain patterns such as mahogany and walnut add a touch of elegance and sophistication, making them suitable for traditional and luxurious settings.

- Cost: The cost varies depending on the wood species, grade, and thickness. Hardwoods are generally more expensive than softwoods due to their durability and aesthetic appeal. In contrast, softwoods are more affordable and widely available. When selecting, buyers should choose wood that not only meets their budget but also offers value for money. They should also consider additional costs such as finishing materials, adhesives, and tools when calculating the total cost of the project.

- Wood sheet size: The size of the sheet affects the number of seams and joints in the installation. Large sheets create a continuous and seamless appearance, especially for countertops, tables, and cabinetry. On the other hand, small sheets are easier to handle and install but require more seams, which can affect the aesthetics and structural integrity. When choosing, buyers should consider the size of the project, the available space, and the budget.

wooden sheet Q&A

Q: How can one protect their wood sheets against moisture damage?

A: Moisture damage can be reduced by sealing the wood with a water-resistant sealant. It is important to also store the wood in a dry place and ensure the storage area is well ventilated.

Q: How can one prevent their wood from warping?

A: To prevent the wood from warping, one can minimize exposure to extreme heat and moisture changes. One can also apply a protective finish to help maintain wood stability. It is also important to store the wood in a flat, level position.

Q: How can one tell if the wood is of good quality?

A: High-quality wood is smooth, easy to cut, and does not have any loose or rough grain. It is also lighter in color and has a consistent texture. The wood should also have minimal cracks and knots.

Popularity Trends

The keyword "wooden sheet" shows a consistent average monthly web search volume of 5,400, with no significant changes observed over the past year. This stability is evident from the lack of percentage changes in both the three-month and one-year periods, maintaining a steady interest in this product.

Analyzing the web search volume trends for "wooden sheet" reveals a pattern of stability with minor fluctuations. For instance, in January 2024, web searches dipped to 4,400 before promptly returning to the average of 5,400 in the following months. This brief decrease does not appear to have affected the overall trend, which quickly reverts to its usual volume. The data from November 2023 through October 2024 consistently reports 5,400 web searches, except for the mentioned dip in January.

This consistent web search volume for "wooden sheet" suggests a steady demand throughout the year, with no notable seasonal variations impacting the search patterns. The quick recovery from the January dip further underscores the robust, ongoing interest in this product category. This analysis indicates that the market for wooden sheets remains stable and resilient to short-term fluctuations.