workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

workstation workbench

Types of workstation workbench

Workstation workbenches are available in various types. Each type is intended for a particular purpose or industry. Here is the categorization:

Industrial Workbench

Industrial workstations are large production tables in an assembly plant with many levels of substance. They are constructed to withstand heavy use and usually have an unyielding top surface and a strong framework.

This kind of workbench is suitable for workshops and factories because it can all hold large equipment and huge workpieces. They are often made from steel or other robust materials.

Computerized Workbench

An electronic workbench is a workstation occupied with data and computer-aided tasks for activities like design or research. It typically features vital computing devices such as PCs or monitors. Also, it has software and hardware for mechanical engineering.

These workbenches are frequently observed in departments like engineering and R&D. These workstations are intended for digital work, which requires an outstanding visual presentation and processing speed. This is why it is a popular option in design-heavy industries.

Workbench-Powered Workbench

A workbench with an employee’s desk integrated into the arrangement is called a lifting workbench. This workbench helps in the change of working heights, thereby suggesting effective sitting and standing work conditions to the users.

It is commonly applied in tasks that include long-duration activities, like medical institutions or call centers. Workers on desks that have lifting workbenches installed under them can easily adjust their working heights.

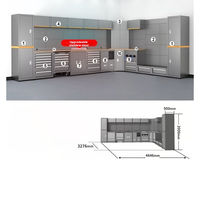

Workbench with Storage

A workbench with lots of storage places many shelves, cupboards, and various storage solutions underneath or close to the work surface. These benches are great for industries where tools and materials need to be close to each other while being organized, such as garages and workshops.

Mobile Workbench

The mobile workbench is a great improvement for easy operations. The workbench is mounted on wheels. Therefore, it can be conveniently relocated and effectively utilized in diverse areas of the building, depending on demands. This proves useful in settings like manufacturing plants or warehouses, where processes change frequently.

Industrial application of workstation workbench

There are many industrial applications of workstation workbench. Some of them are:

Manufacturing

Workbenches are used to do work in manufacturing plants. They produce parts and assemble hardware. Manufacturing workstations are designed to contain tools, machinery, and components necessary for the production process.

They are robust and have huge work surfaces. These features enable operators to carry out assembly and machining works effectively.

Pharmaceutical

Pharmaceutical research requires workbenches for drug creation and testing. These workstations are clean, covered with non-porous surfaces that can easily be sanitized. They help scientists maintain safety and order during experiments.

Logistics

The workstation workbench has storage areas so tools and items can be easily organized and retrieved, making it ideal for warehouses during packing or sorting jobs. They provide logistics and packing facilities by giving personnel the necessary resources.

Automotive

Automotive industries use charging workstations and organizing tools of different sizes and shapes, from screws to huge auto parts. They also have storage locations where materials can easily be stored and retrieved.

Electronics

The electronics sector demands workbenches for circuit board arrangement and device assembly. These should facilitate intricate work by holding tiny components. Electronics workbenches are usually fitted with electrical outlets and anti-static surfaces.

Healthcare

Healthcare institutions utilize automotive workbenches during surgery, treatment preparation, and equipment sterilization. They should be designed for cleaning and make it convenient for practitioners to organize instruments better than before.

Aerospace

The aerospace industry demands computerized benches for designing flight vehicles and testing space equipment. They should support complicated design software and hold huge machines. They are widely utilized in engineering and R&D tasks in this sector due to strength and accuracy.

Product design of workstation workbench

Workstation workbench is a key feature for all industrial operations. Particulars of their design impact their operation.

Material

The material of the workbench matters. It sells them durability and impact resistance. Benchtops in industrial applications are frequently constructed of steel. Wood provides a smooth surface but is less scrubbed. Laminated wood is economical and more adaptable.

Ergonomics

The best work area is workstation workbenches. They help in reducing operator stress and maximize efficiency. It allows easy access to tools and materials. They ensure operators carry out their tasks without bending or stretching uncomfortably.

Workspace

The size of the workspace depends on the operations it will host. Large-scale jobs require a vast surface for complex assembling and integrating. These benches handle big tasks since they are large. Surface-mounted workbenches like flip-flop benches are perfect for small tasks where a surface should be portable.

Load Capacity

This depends on the type of industry it will be used in. The standard lifting table workbench can lift around 1100 kg. However, some of the heavy-duty lifting worktables can lift more than 2200 kg.

Mobility

Mobility works best when there is flexibility, and there is a stationary workbench. Mobile workbenches have swivel locks. Hence, it can be moved freely whenever mobility is needed, and it can be locked in position for stability.

Workbench Height

This feature makes it possible for the user to work ergonomically. The workbench height can be adjusted to make it convenient for most users. The lifting table workbench can be adjusted automatically to achieve the correct working posture.

Customization

Customizing workstations will be more advantageous. It ensures existing layout and workflows are maintained without redesigning the whole place.

Choosing a workstation workbench

Choosing the right workstation workbenches involve analyzing numerous factors. Some talk-throughs include:

Workbench Requirements vs. Bench Specifications

There are operational demands that require specific features. What are the tasks to be done on this workbench? Is the workbench going to be used for light or heavy work? These questions will help in choosing the workstation.

Hosting Capability

A workbench must host all the instruments and equipment required during the operations. This can be done through a workstation with huge surface hosts. Info regarding hosting capability can be found online or within the hosting tool producers.

Mobilization

The operations that need flexibility will require a mobile workstation. These are perfect for shifting tasks in various parts of the enterprise. But if the task is going to be done in a fixed place, it will be better to have a stationary workstation. They are more robust and offer better stability than the latter.

Height Adjustment

This is super flexible. When placing a workstation, height adjustment is an important factor for users of various stature. The best choice would be a lifting workbench if there is a constant change of staff that needs different ergonomic working postures.

Investing in Quality

Workstations should be low-maintenance and have a long life. Various features like powerful motors and coatings help reduce maintenance costs and downtime. Many quality workspaces come with warranties.

Assessment of Space

When assessing space, check the area. Consider the environment where employees will be working. Study the place before bringing in the workbench and obstructing movement. Also, consider the optional mobility workbench.

Collaborating with Stakeholders

The best way to get to the heart of the matter is by working closely with stakeholders. At each level of production, get their opinion about the workbench. They will have the best ideas about what is required to make their workstation efficient.

Q&A

Q1: Which factors influence workstation workbench styles the most?

A1: Industrial applications, work size, tasks, and space influence workstation workbench styles.

Q2: Do all workstation workbenches have height adjustability?

A2: No. Only workstation workbenches that require flexibility have height adjustability. The others are fixed and stationary.

Q3: What is the composition of workstation workbench top surfaces?

A3: They consist of laminated wood, solid wood, and steel.

Q4: Which industry uses workbenches more frequently?

A4: Workbench designs are not restricted to any one industry. Electronics and automotive top-workbench usage surveys.

Q5: Why are ergonomic features essential in a workstation workbench?

A5: They help operators work comfortably while reducing strain.