4.5'' 115x22mm ULTIMATE 100 Vsm Abrasive Flap Disc Flap Disc Making Machine

Other recommendations for your business

Contact us

Quik Detail

| warranty | 3 years |

|---|---|

| customized support | OEM, ODM, OBM |

| place of origin | Zhejiang, China |

| brand name | PEGATEC |

| model number | PFD115VZA1 |

| type | Abrasive Disc |

| Name | 4.5'' 115x22mm ULTIMATE 100 vsm zirconia flap disc |

| Material | Zirconium |

| Substrate | Cloth |

| Outer Diameter | 115mm |

| Inner Diameter | 22.2mm |

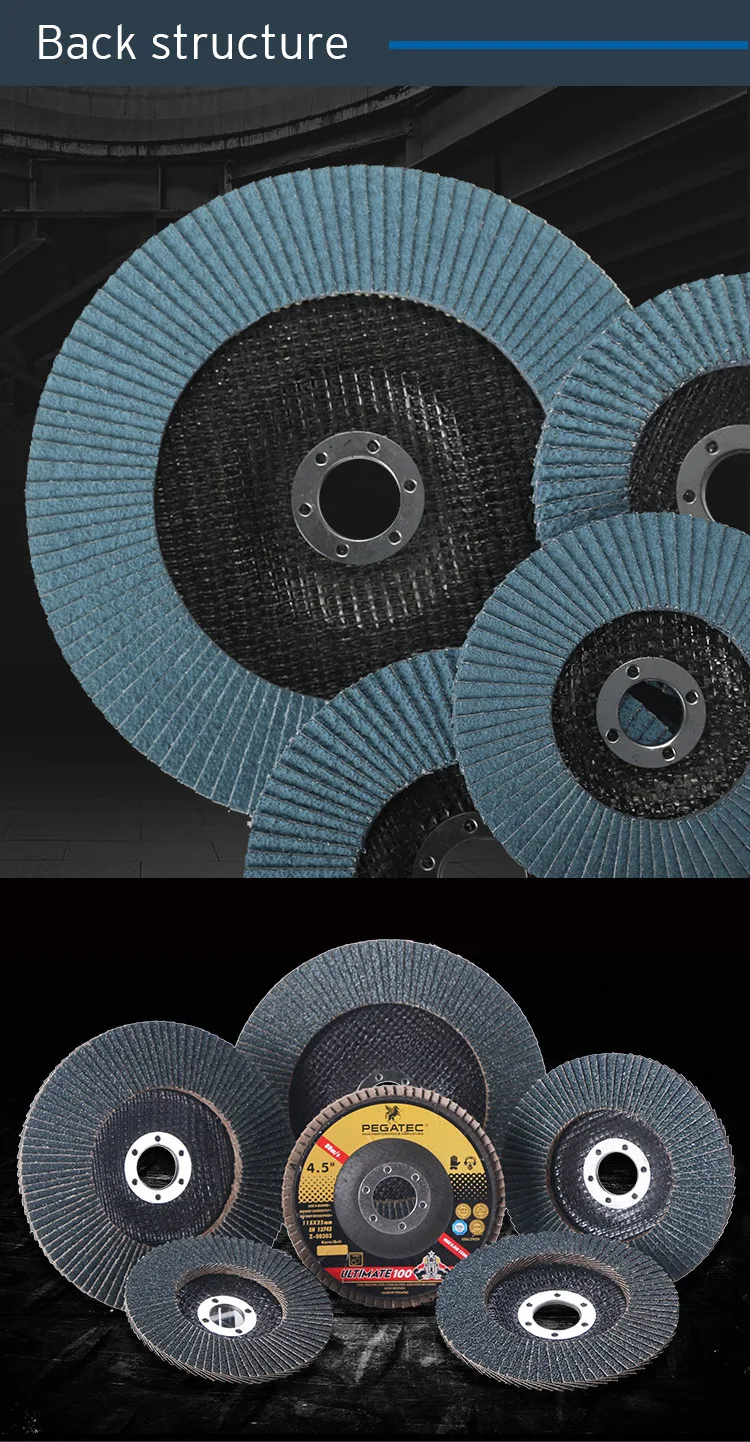

| color | blue |

| Usage | stainless steel, inox |

| Grit | 60# |

| Type | T27,T29 |

| Certification | ISO |

Product Detail

| PRODUCT DECRIPTION |

|

4.5'' 115x22mm ULTIMATE 100 vsm zirconia flap disc

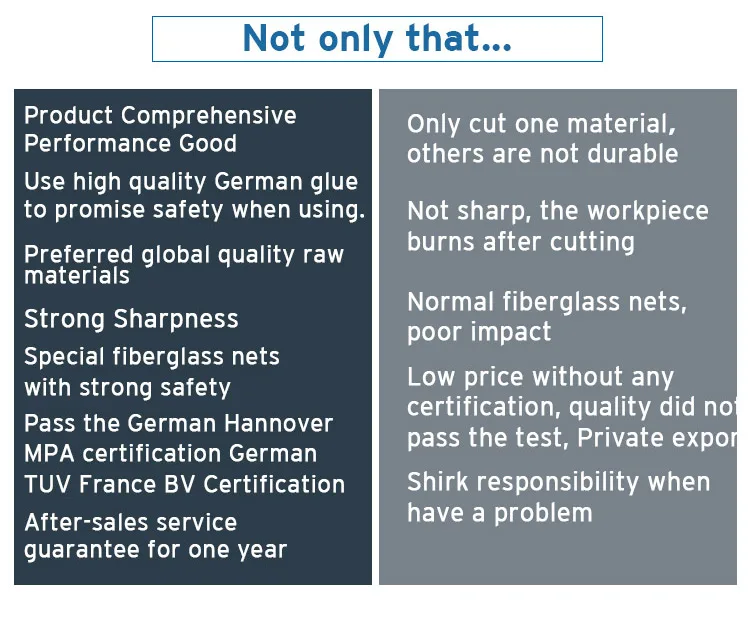

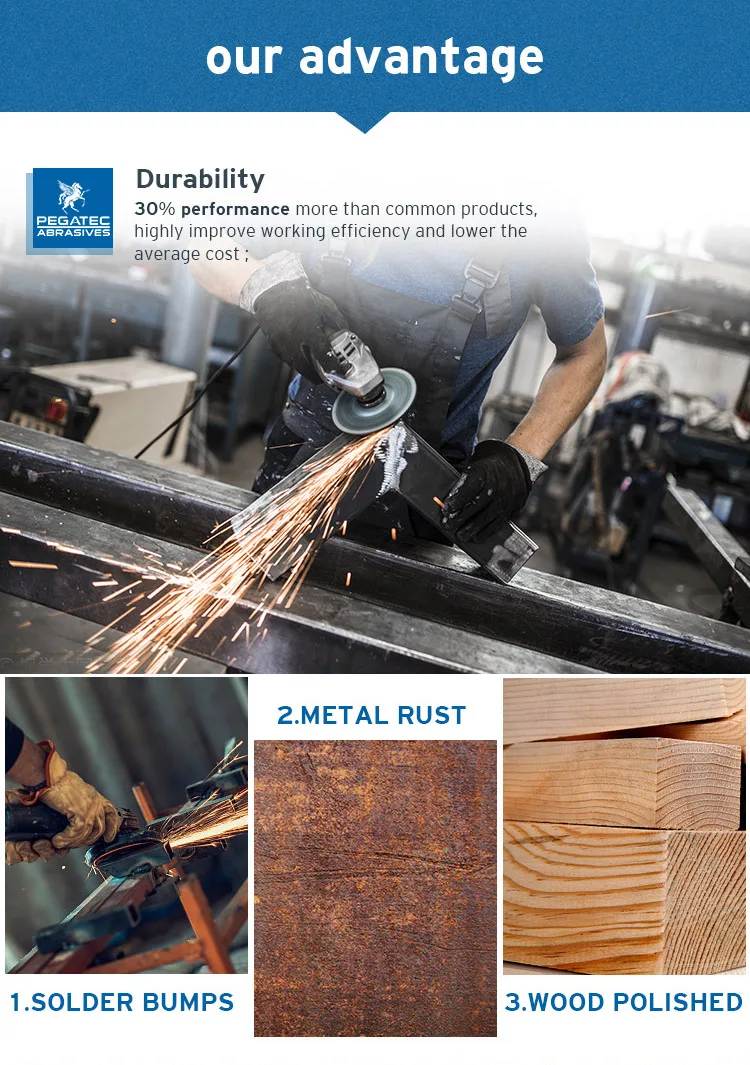

It is fit for reclamation grinding.Compared with ordinary products,it promotes 30% performance and is easy to unplug the workpiece layer by layer and achieves the effect you want.Meanwhile,its raw material with high performance can effectively prevent the hot corrsion in grinding and during using you will find the bright workpiece surface after grinding. |

| Product Specification | Packing & Shipping |

| Item No. | PFD115VZA1 | Color box size | 62.5X25.5X12.5CM |

| Max Speed | 80M/S | Qty/Ctn | 10/100PCS |

| Material | VSM ZIRCONIA | G.W. | 8KGS |

| Logo | ULTIMATE100 | N.W. | 7KGS |

| Use | POLISHING STEEL&INOX | MOQ | 3000PCS |

| Certificate | MPA EN13743,TUV,ISO9001:2008 | Loading port | NINGBO/SHANGHAI PORT |

| HS code | 6805100000 | Payment items | T/T , L/C, TRADE ASSURANCE |

| Samples | Free sample to send you to check quality for order confirmation | Delivery time | 30-45 days after receive the deposit |

|

Winking Abrasives Co., Ltd., a famous specialized resin abrasive tools manufacturer, one of the most influential companies in Asia.

With 38 years of manufacturing experience, we create unique competitiveness. "Sharp! Accurate! Durable!" is the standard of our products. Our cutting wheels and grinding wheels,flap discs are now exporting to more than 100 countries and more than 30 agents around the world.

We pay 100% attention to quality. We never take chance in raw material. Each working procedure is treated with the most rigorous attitude and the advanced enviroment control. It makes each grain of raw material maximizing the performance and then ensure the high quality and stability of products. All our cutting wheels and grinding wheels will pass the semi-product testing, finished-product testing and inspection before delivering. Quality passes only after 3 times testing. |

|

FAQ

|