FETECH Box Crusher with High Torque and Advanced Shredding Blades Mining Box Crushing Machinery for Gypsum Dolomite Quartzite

US $8,200.00-8,500.00 / set

1 set(s)Minimum order

Type:

Jaw Crusher

Application:

Ore Rock Crushing

Capacity(t/h):

300-400t/h

Place of Origin:

Guangdong, China

Brand Name:

FETECH

Dimension(L*W*H):

1800*1800mm

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Jaw Crusher |

|---|---|

| Application | Ore Rock Crushing |

| Capacity(t/h) | 300-400t/h |

| Place of Origin | Guangdong, China |

| Brand Name | FETECH |

| Dimension(L*W*H) | 1800*1800mm |

| Weight | 6200 KG |

| Warranty | 1.5 years |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Engine |

| Key Selling Points | High Productivity |

| Product name | Jaw Crusher |

| After sale service | Engineer Overseas Service |

| Capacity | Customized |

| After-sales Service Provided | 0.5-3 Year Flexible Warraty |

| Factory Visit | Welcomed Warmly |

| Applicable Industries | Energy & Mining |

| Showroom Location | Canada, Turkey, United States, Brazil, Peru, Saudi Arabia, Indonesia, India, Mexico, Thailand, Morocco, Kenya, Argentina, Chile, Colombia, Algeria, South Africa, Kazakhstan, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia |

| Condition | New |

| Warranty of core components | 1 Year |

| Marketing Type | New Product 2024 |

Product Detail

Jaw Crusher Introduction

Jaw crusher is a compression type crusher, usually used as a primary crusher set at the very front of the ore or rock crushing plant to reduce hard rock size. Jaw rock crushers are commonly double-toggle jaw crushers, composed of a fixed jaw and moving jaw,the discharging stone particle size can be controlled by changing the discharge port. Owing to their high crushing capacity and hard material efficiency, jaw crushers are a good alternative to primary gyratory crushers.

Jaw Crusher Types

1. Single toggle jaw crushers and double toggle jaw crushers.

2. Industrial jaw crushers and laboratory small jaw crushers.

3. Diesel engine jaw crushers & Electric jaw crushers.

4. Hydraulic jaw crushers

5. Stationary & mobile jaw crusher(track mounted jaw crusher).

6. PEX / PE jaw crusher.

Jaw Crusher Types

1. Single toggle jaw crushers and double toggle jaw crushers.

2. Industrial jaw crushers and laboratory small jaw crushers.

3. Diesel engine jaw crushers & Electric jaw crushers.

4. Hydraulic jaw crushers

5. Stationary & mobile jaw crusher(track mounted jaw crusher).

6. PEX / PE jaw crusher.

Advantages of Box Crusher

Box crushers, also known as box shredders or box crushers for cardboard, offer several advantages:

1.Space Efficiency: They compress cardboard and other materials into compact bundles, saving space in storage and uring transportation.

2.Cost Savings: By reducing waste volume, they can lower disposal costs and optimize recycling processes.

3.Ease of Use: Many box crushers are user-friendly, allowing operators to process large volumes of material quickly and with minimal effort.

4.Improved Safety: By handling large boxes or cardboard sheets more safely, they can reduce the risk of workplace injuries associated with manual handling.

5.Environmental Benefits: They promote recycling and waste reduction, supporting sustainability initiatives.

6.Versatility: Some models can handle various materials beyond cardboard, including plastic and paper, making them versatile tools for waste management.

Increased Efficiency: They can significantly speed up the processing of waste materials compared to manual methods.

Application of Box Crusher

Mining box crusher, often referred to as a box or hammer crusher, is commonly used in the mining and construction industries for various applications. Here are some of its primary uses:

1.Crushing Ore: It is primarily used to crush ore into smaller pieces, making it easier to extract valuable minerals.

Material Size Reduction: The crusher reduces larger chunks of material into smaller, manageable sizes for further processing or transportation.

2.Rock Breaking: In mining operations, it breaks down hard rock into fragments that can be transported to processing facilities.

3.Aggregate Production: It's used in producing aggregates for construction, such as gravel, sand, and crushed stone.

4.Coal Preparation: In coal mining, it crushes coal to a suitable size for further processing or combustion.

5.Recycling: It can be used to crush waste materials from construction and demolition sites, allowing for the recycling of materials.

6.Sand Making: Some designs can produce finer materials, which can be used for sand production.

Model | 700*1000 | 900*1200 | 1000*1000 | 1200*1200 | 1400*1400 | 1600*1600 | 1800*1800 |

Roller Diameter(mm) | 700 | 900 | 1000 | 1200 | 1400 | 1600 | 1800 |

Roller Length(mm) | 1000 | 1200 | 1000 | 1200 | 1400 | 1600 | 1800 |

Capacity(t/h) | 50-80 | 70-100 | 90-120 | 130-160 | 190-210 | 250-300 | 300-400 |

Feeding Size(mm) | ≤500 | ≤800 | ≤800 | ≤900 | ≤1000 | ≤1000 | ≤1200 |

Power(kw) | 45-55 | 55-75 | 55-75 | 75-90 | 132-150 | 160-210 | 280-320 |

Company Profile

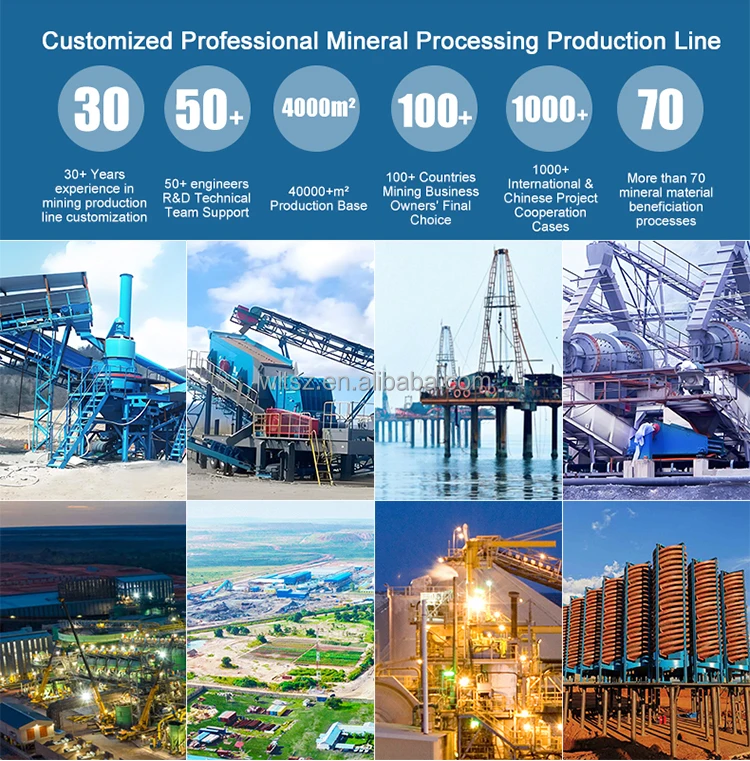

Company Profile: Future Explorer Technical Eqiupment Co.,Ltd (FETECH)

Future Explorer Technical Eqiupment Co.,Ltd was founded in 2015. It is a mining service organization specializing in mining machinery manufacturing, mineral analysis, and mineral processing equipment design, installation and commissioning.

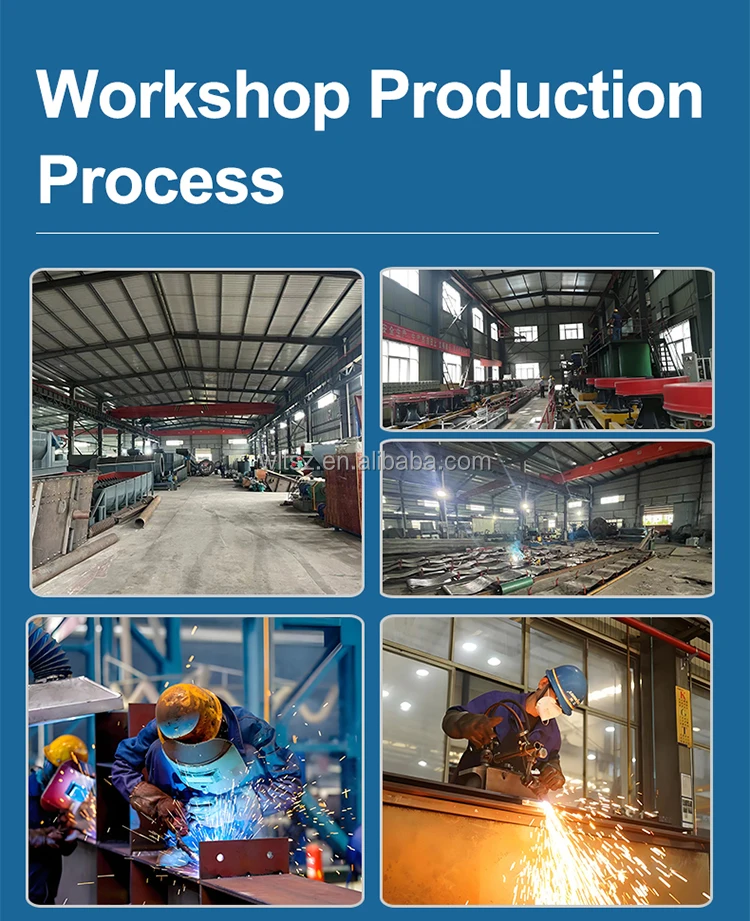

The R&D technical team is located in Shenzhen, Guangdong,a high-tech industry gathering city in China. The factory is located in Shicheng County, Jiangxi Province, covering an area of around 40,000m². It has more than 200 sets of large-scale modern mechanical processing equipment, smelting and casting equipment, and more than 50 professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation engineers, including 10+ senior engineers, 30+ junior engineers, and 150+ workers.supporting our company's strong production and supply capabilities.

For more than 20 years, we have focused on the R&D, design and production of mining mineral processing equipment. The core founding team has independently designed and developed customized production line one-stop solutions for mining projects in 100+ countries around the world based on customer needs and the local geographical environment of the mine. Including on-site survey, product design, manufacturing, installation, commissioning and after-sales service. In addition,We also maintain long-term cooperation with international and Chinese scientific research institutions of universities to explore new and efficient technologies, improving economic efficiency while protecting the environment

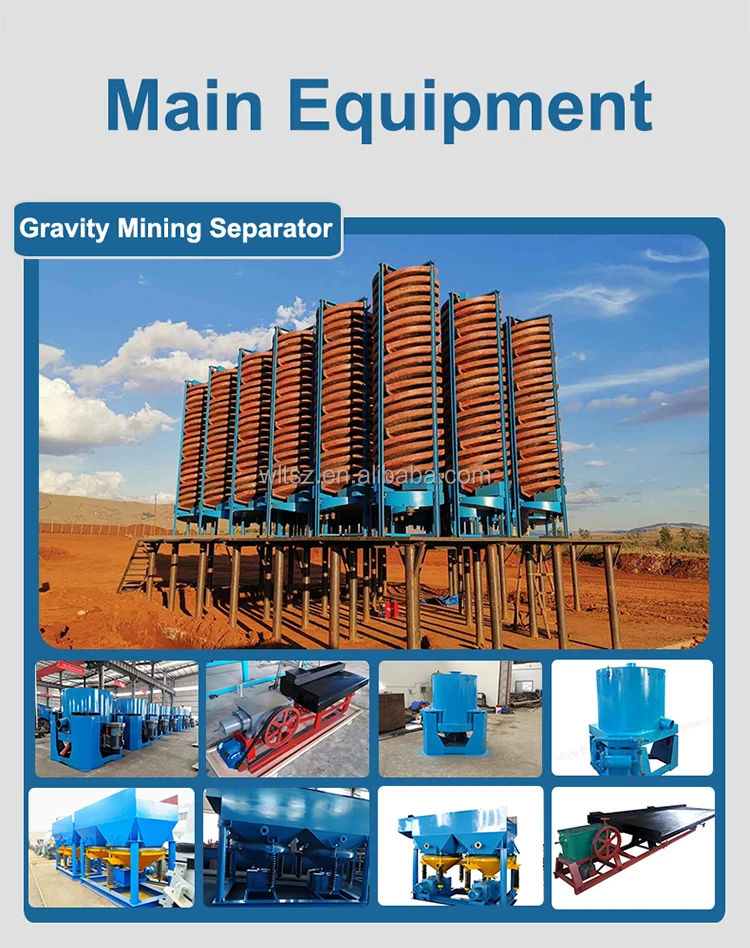

Main products: customized production line solutions for mines, ore washing equipment, gravity separation equipment, flotation equipment, magnetic separation equipment, crushing and grinding equipment, screening and classification equipment, feeding and conveying equipment, mineral processing experimental equipment, excavation equipment and transportation equipment , mobile mining crushing production equipment, sand dredgers, dredgers and other large equipment. Mainly used in mining, coal, quarry, scrap metal recycling and other fields.

Our products have passed ISO9001, ISO27001, ISO17020, SGS,IECEX, MSHA, ATEX, ANZEX, CERTEX, GOST-R, IRMA certification

Our products sell well all over the world:

1. Oceania: Australia, New Zealand

2 Africa: South Africa, Sudan, Zimbabwe, Ghana, Tanzania, Uganda, Congo, Zambia, Nigeria,

3 Americas: United States,Canada, Brazil, Mexico

4 Europe: Romania, Sweden

5 Asia: South Korea, India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan, Kyrgyzstan, Tajikistan, Turkmenistan, Turkey, Papua New Guinea

Why Choose FETECH ? (Future Explorer Technical Eqiupment Co.,Ltd )

EPC+M+O Mode (Engineer,Procure,Construct + Operation + Maintenance )30+Years experience in mining production line customization

50+engineers R&D Technical Team Support

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

50+engineers R&D Technical Team Support

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

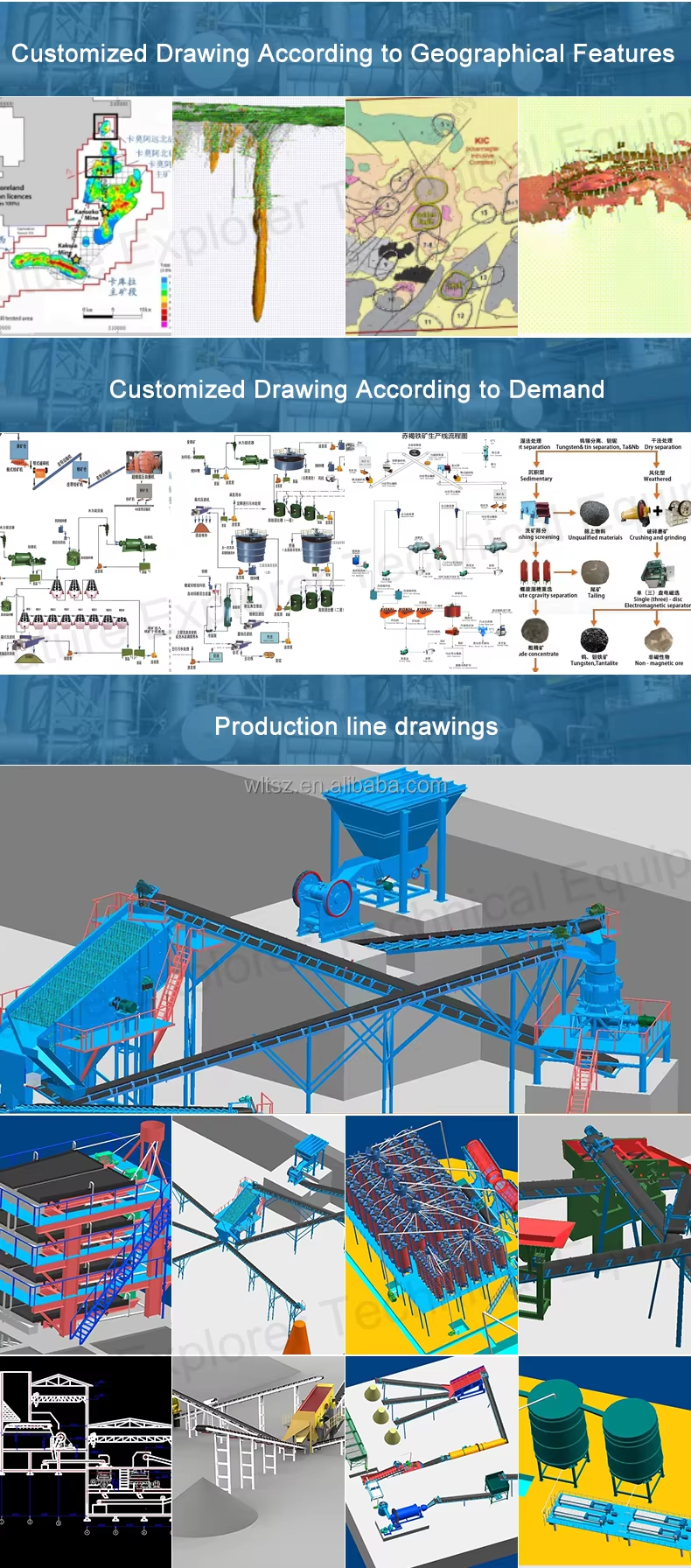

Engeering Design Drawings in the past

The pictures above are engineering modeling design drawings produced based on the on-site terrain and needs of the mine in our company's successful cases.

Global Sales Network:

1. Oceania: Australia, New Zealand 2.Africa: South Africa, Sudan, Zimbabwe, Ghana,Tanzania, Uganda, Congo, Zambia, Nigeria,

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

Customer Photos

Certifications

333