FETECH LL-1200 1500 2000 Spiral Classifier Gravity Separator for Ore Chromite Chromium Ferrum Spiral Chute Concentrator

1 set(s)Minimum order

Type:

Sprial Separator, Gravity Separator

Production Capacity:

0.1-40 Ton /Hour

Place of Origin:

Guangdong, China

Brand Name:

FETECH

Voltage:

0

Dimension(L*W*H):

106*106*400cm

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Sprial Separator, Gravity Separator |

|---|---|

| Production Capacity | 0.1-40 Ton /Hour |

| Place of Origin | Guangdong, China |

| Brand Name | FETECH |

| Dimension(L*W*H) | 106*106*400cm |

| Weight | 500 KG |

| Warranty | 1 Year |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Other, Fiber Glass |

| Key Selling Points | High Productivity Long working Life |

| Product name | Spiral Chute Separator for Iron Titanium Chromium |

| MOQ | 1 Set |

| Processing capacity | Capacity Customizable |

| After-sales Service Provided | 0.5-10 Year Flexible Warraty |

| Factory Visit | Welcomed Warmly |

| Function 1 | sorting iron,ilmenite,chromite,pyrite,zircon,rutile,monazite |

| Function 2 | sorting phosphotyrite,tungsten,tin,tantalum,niobium |

| Application | Iron Titanium Chromium Tungsten Tantalum Niobium Tin Gold |

| Applicable Industries | Energy & Mining |

Product Detail

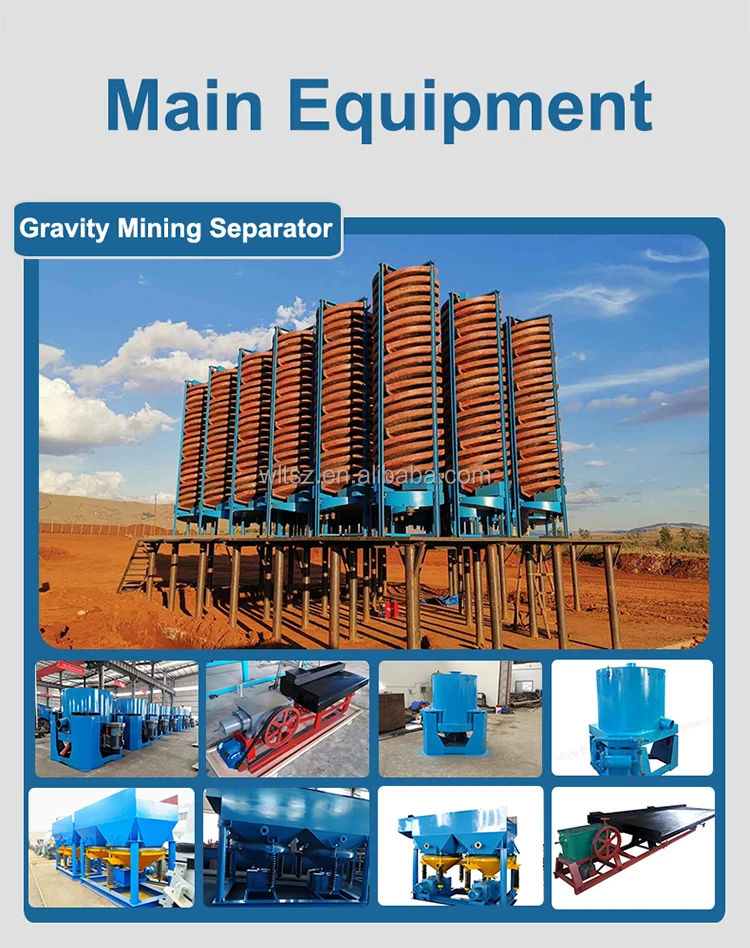

Spiral Chute Separator

Spiral Chute is the best equipment for mining and mineral processing, which combines the characteristics of the spiral concentrator, shaking table, and Centrifugal concentrator. It is made of fiberglass lined with wear-resistant polyurethane and corundum cover, light moisture-proof, anti-rust.

The spiral separator has the advantages of a small occupation area, small water consumption, simple structure, no energy consumption, large capacity, easy installation, easy operation, and small investment.

We supply different types of gravity separation equipment, such as gold centrifugal concentrators, shaking tables, and wet spiral concentrators(see our Mining equipment list). Spiral classifier applied in different conditions of extraction process dense media separation. Besides, the spiral chute design is available. Email us to know the spiral classifier price.

The spiral separator has the advantages of a small occupation area, small water consumption, simple structure, no energy consumption, large capacity, easy installation, easy operation, and small investment.

We supply different types of gravity separation equipment, such as gold centrifugal concentrators, shaking tables, and wet spiral concentrators(see our Mining equipment list). Spiral classifier applied in different conditions of extraction process dense media separation. Besides, the spiral chute design is available. Email us to know the spiral classifier price.

Model | 5LL-2000 | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 | ||

Diameter Size (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | ||

Screw Pitch(mm) | 1000 | 810、720、540 | 720、540 | 540 | 400 | 210 | ||

Gradient (°) | 9° | 9° | 9° | 9° | 9° | 9° | ||

Num. Of Threads | 3 | 4 | 4 | 4 | 3 | 2 | ||

Num. Of Turns | 4 | 4-5 | 4-5 | 4-5 | 5 | 5 | ||

Feeding Size (mm) | 2.5-0.074 | 2.5-0.074 | 0.3-0.03 | 1-0.074 | 2-0.074 | 1-0.074 | ||

Feeding Density (%) | 15-40 | 25-50 | 25-55 | 25-55 | 25-55 | 25-55 | ||

Capacity (t/h) | 10-15 | 5-7 | 3-5 | 1.5-2.5 | 0.8-1.5 | 0.1-0.5 | ||

Length | 2300 | 1560 | 1360 | 1060 | 700 | 460 | ||

Width | 2300 | 1560 | 1360 | 1060 | 700 | 460 | ||

Height | 5700 | 5230、4360 | 5230/4360 | 4200/4700 | 2150 | 1500 | ||

Company Profile

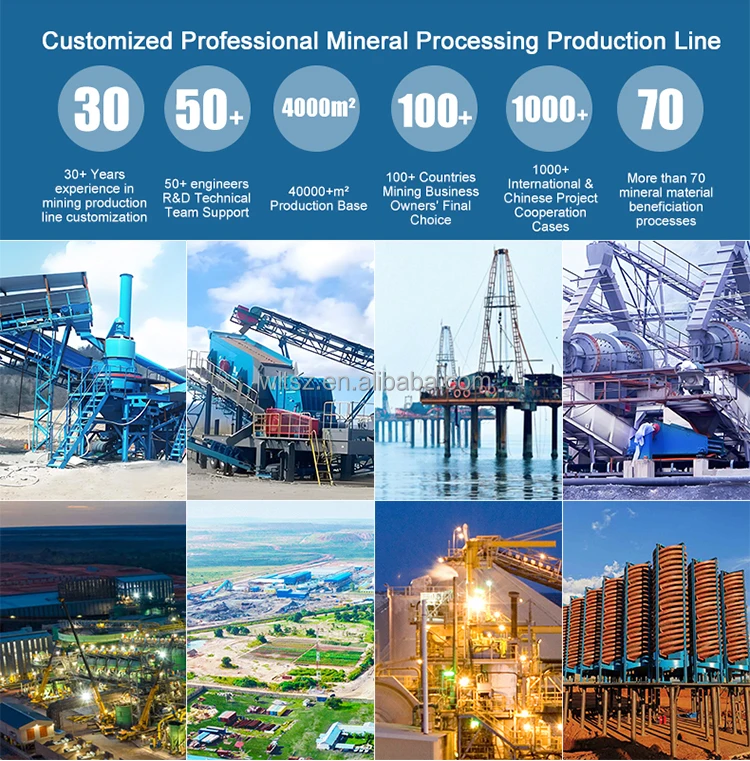

Company Profile: Future Explorer Technical Eqiupment Co.,Ltd(FETECH)

Future Explorer Technical Eqiupment Co.,Ltd was founded in 2015. It is a mining service organization specializing in mining machinery manufacturing, mineral analysis, and mineral processing equipment design, installation and commissioning.

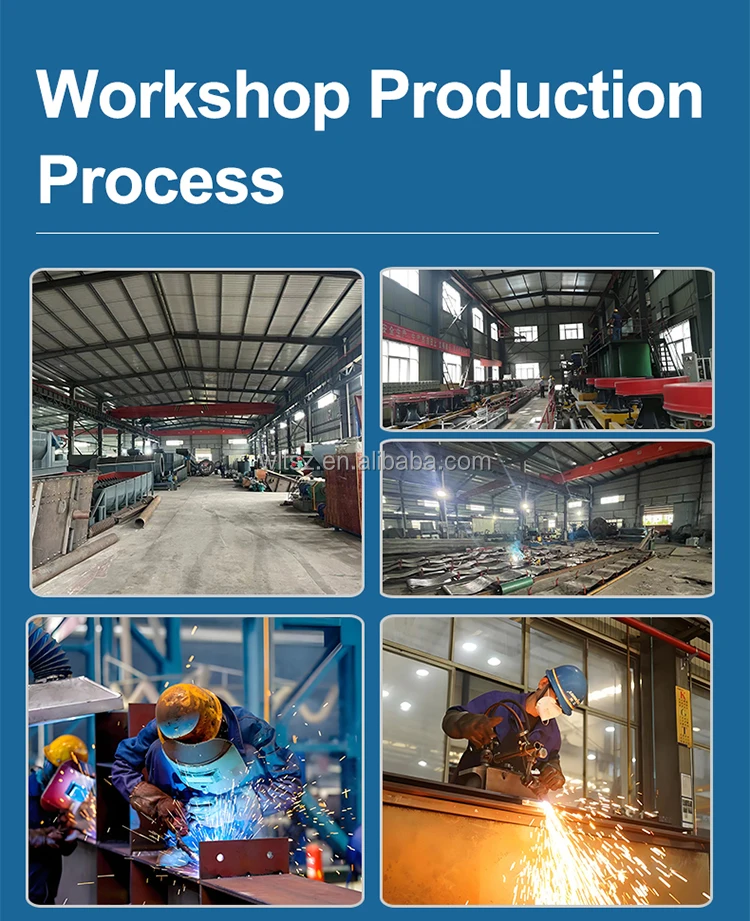

The R&D technical team is located in Shenzhen, Guangdong,a high-tech industry gathering city in China. The factory is located in Shicheng County, Jiangxi Province, covering an area of around 40,000m². It has more than 200 sets of large-scale modern mechanical processing equipment, smelting and casting equipment, and more than 50 professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation engineers, including 10+ senior engineers, 30+ junior engineers, and 150+ workers.supporting our company's strong production and supply capabilities。 For more than 30 years, we have focused on the R&D, design and production of mining mineral processing equipment. The core founding team has independently designed and developed customized production line one-stop solutions for mining projects in 100+ countries around the world based on customer needs and the local geographical environment of the mine. Including on-site survey, product design, manufacturing, installation, commissioning and after-sales service. In addition,We also maintain long-term cooperation with international and Chinese scientific research institutions of universities to explore new and efficient technologies, improving economic efficiency while protecting the environment

Main products: customized production line solutions for mines, ore washing equipment, gravity separation equipment, flotation equipment, magnetic separation equipment, crushing and grinding equipment, screening and classification equipment, feeding and conveying equipment, mineral processing experimental equipment, excavation equipment and transportation equipment , mobile mining crushing production equipment, sand dredgers, dredgers and other large equipment. Mainly used in mining, coal, quarry, scrap metal recycling and other fields.

Our products have passed ISO9001, ISO27001, ISO17020, SGS,

IECEX, MSHA, ATEX, ANZEX, CERTEX, GOST-R, IRMA certification

IECEX, MSHA, ATEX, ANZEX, CERTEX, GOST-R, IRMA certification

Why Choose FETECH ? (Future Explorer Technical Eqiupment Co.,Ltd )

EPC+M+O Mode (Engineer,Procure,Construct + Operation + Maintenance )30+Years experience in mining production line customization

50+engineers R&D Technical Team Support

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

50+engineers R&D Technical Team Support

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

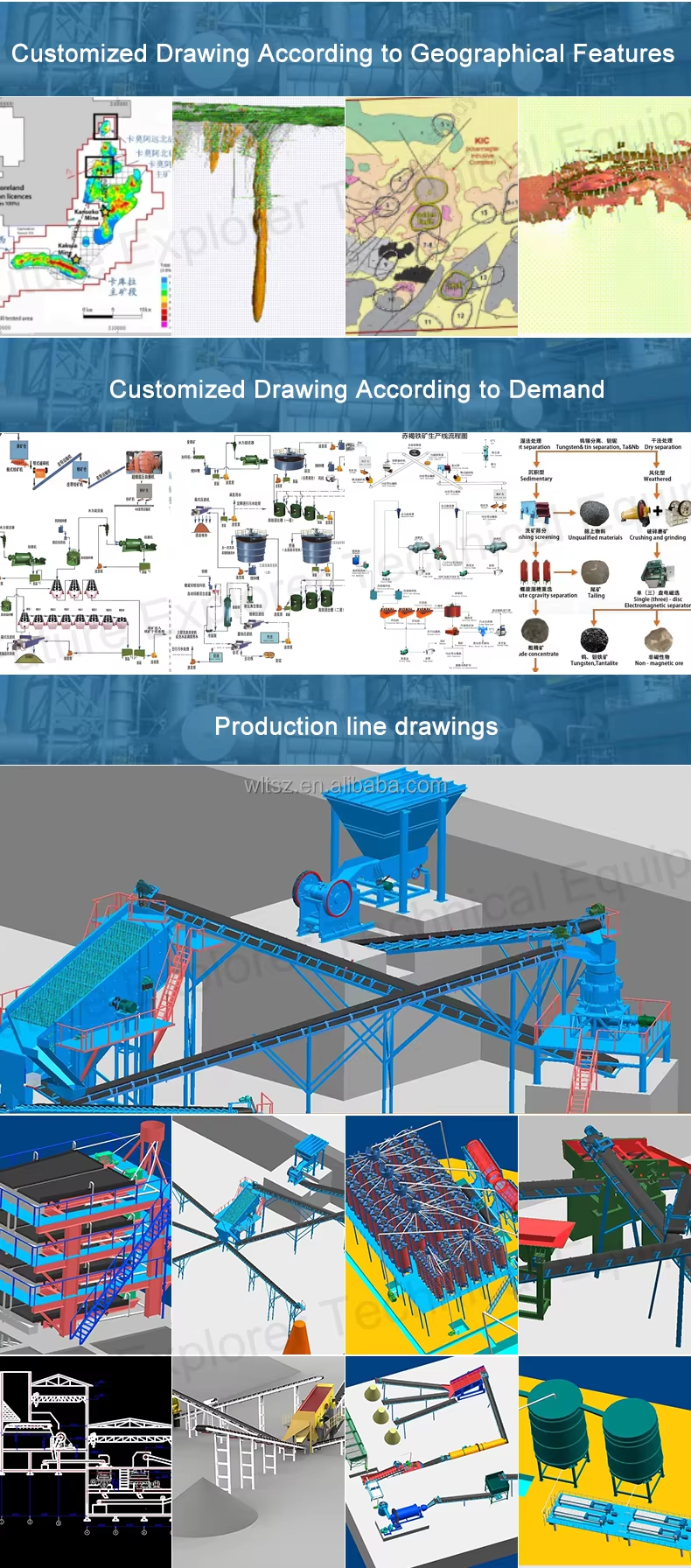

Engeering Design Drawings in the past

The pictures above are engineering modeling design drawings produced based on the on-site terrain and needs of the mine in our company's successful cases.

Global Sales Network:

1. Oceania: Australia, New Zealand 2.Africa: South Africa, Sudan, Zimbabwe, Ghana,

Tanzania, Uganda, Congo, Zambia, Nigeria,

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,

Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

Tanzania, Uganda, Congo, Zambia, Nigeria,

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,

Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

Customer Photos

Certifications