FETECH Leaching Tank Equipment SJ2.0x2.5 Long Service Life AC Motor Customized Applicant Zinc Smelting Screening Machine

US $2,000.00-3,000.00 / set

1 set(s)Minimum order

Type:

Sprial Separator

Production Capacity:

Customized

Place of Origin:

Jiangxi, China, Jiangxi,China

Brand Name:

FETECH, FETECH

Voltage:

380V, 220V

Dimension(L*W*H):

Customized, Customized

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Sprial Separator |

|---|---|

| Production Capacity | Customized |

| Place of Origin | Jiangxi, China, Jiangxi,China |

| Brand Name | FETECH, FETECH |

| Voltage | 380V, 220V |

| Dimension(L*W*H) | Customized, Customized |

| Weight | 1000 KG |

| Warranty | 1 Year |

| Machinery Test Report | Provided, Provided |

| Video outgoing-inspection | Provided, Provided |

| Core Components | motor, Engine, PLC, Bearing, Other, Motor,Engine |

| Key Selling Points | Long Service Life |

| Product Name | Leaching Tank |

| Size | Customized |

| Color | Customized |

| Application | Zinc, Smelting |

Product Detail

Product Description

Specification

Model | Cell(diameter×Height)(mm) | Effective Volume(m³) | Impeller | Diameter(mm) | ||||

Rotation Speed(rpm) | Diameter(mm) | Feeding Tube | Output Tube | Total Weight | ||||

SJ2.0×2.5 | 2000×2500 | 6 | 52 | 909 | 2-φ133 | 2-φ133 | 2144 | |

SJ2.5×3.15 | 2500×3150 | 13 | 52 | 935 | 2-φ125 | 2-φ125 | 3095 | |

SJ3×3.15 | 3000×3150 | 18.9 | 43 | 1130 | 2-φ150 | 2-φ150 | 4160 | |

SJ3.55×4.0 | 3550×4000 | 35 | 43 | 1310 | 2-φ150 | 2-φ150 | 5025 | |

SJ4.0×4.5 | 4000×4500 | 48 | 35 | 1750 | 2-φ150 | 2-φ150 | 7569 | |

SJ4.5×5.0 | 4500×5000 | 71.6 | 35 | 1750 | 2-φ159×6 | 2-φ159×6 | 10864 | |

SJ5.0×5.6 | 5000×5600 | 98 | 31 | 2046 | 2-φ159×8 | 2-φ159×8 | 14291 | |

SJ5.5×6.0 | 5500×56000 | 112 | 31 | 2100 | 2-φ159×8 | 2-φ159×8 | 18745 | |

SJ6.5×7.0 | 6500×7000 | 195 | 21 | 2400 | 2-φ159×8 | 2-φ159×8 | 25978 | |

SJ7.0×7.5 | 7000×7500 | 245.4 | 21 | 2400 | 2-φ159×8 | 2-φ159×8 | 29030 | |

SJ7.5×8.0 | 7500×8000 | 268.6 | 23 | 2900 | 2-φ168×8 | 2-φ168×8 | 32796 | |

SJ8.0×8.5 | 8000×8500 | 319 | 18.5 | 3300 | 2-φ168×8 | 2-φ168×8 | 42467.3 | |

SJ8.5×9.0 | 8500×9000 | 395 | 18.5 | 3300 | 2-φ219×8 | 2-φ219×8 | 46623 | |

Working Principle

When the double impeller leaching mixing tank is working, the pulp will flow from the top to the bottom under the drag and

stirring action of the double impeller, diffuse through the surrounding damping plate, and feed air at the lower end of the shaft to mix with the pulp Circulate upward to form a uniform suspension mixture.

stirring action of the double impeller, diffuse through the surrounding damping plate, and feed air at the lower end of the shaft to mix with the pulp Circulate upward to form a uniform suspension mixture.

Advantages

1. High efficiency metal recovery : leaching tank can effectively extract metal from ore through chemical reaction, improve metal recovery .

2. Easy operation : The operation of leaching tank is relatively simple, easy to control and maintain, suitable for different sizes of concentrator .

3. Strong adaptability : the leaching tank can be adjusted according to different ore properties and process requirements, and has strong adaptability

4. Simple equipment : the leaching tank usually only needs groove and pump and other equipment, the process combination is flexible, the scale can be large or small

5. High leaching rate : SJ type double impeller high efficiency leaching tank can improve the cyanide leaching rate and activated carbon adsorption rate

Application

1. Beneficiation of gold ore : In beneficiation of gold ore, the leaching tank is often used in the cyanide leaching process to dissolve gold from the ore by sodium cyanide solution

2. Mineral processing of copper ore : In copper ore processing, the leaching tank is used for sulfuric acid leaching process, through sulfuric acid solution to extract copper from the ore

3. Beneficiation of other metal ore : leaching tank is also suitable for beneficiation process of other metal ore, through different leaching agents to extract various metals

4. Chemical industry, mineral processing, smelting and other industries : SJ double impeller leaching mixing tank is suitable for small proportion, low viscosity, slow settling rate of ore, widely used in chemical industry, mineral processing, smelting and other industrial industries

Company Profile

Why Choose FETECH ? (Future Explorer Technical Eqiupment Co.,Ltd )

20+Years experience in mining production line customization

50+engineers R&D Technical Team Support

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

We support EPC+M+O Mode (Engineer,Procure,Construct + Operation + Maintenance )

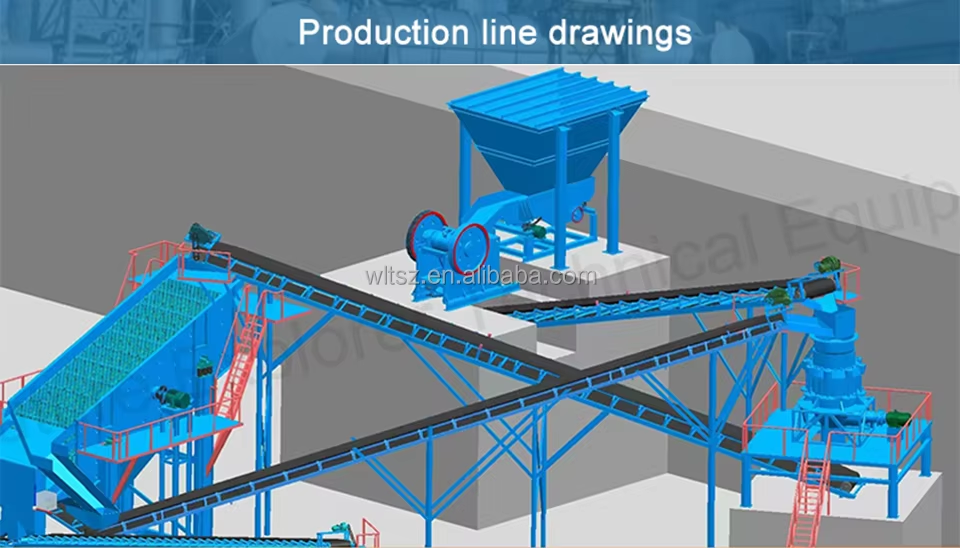

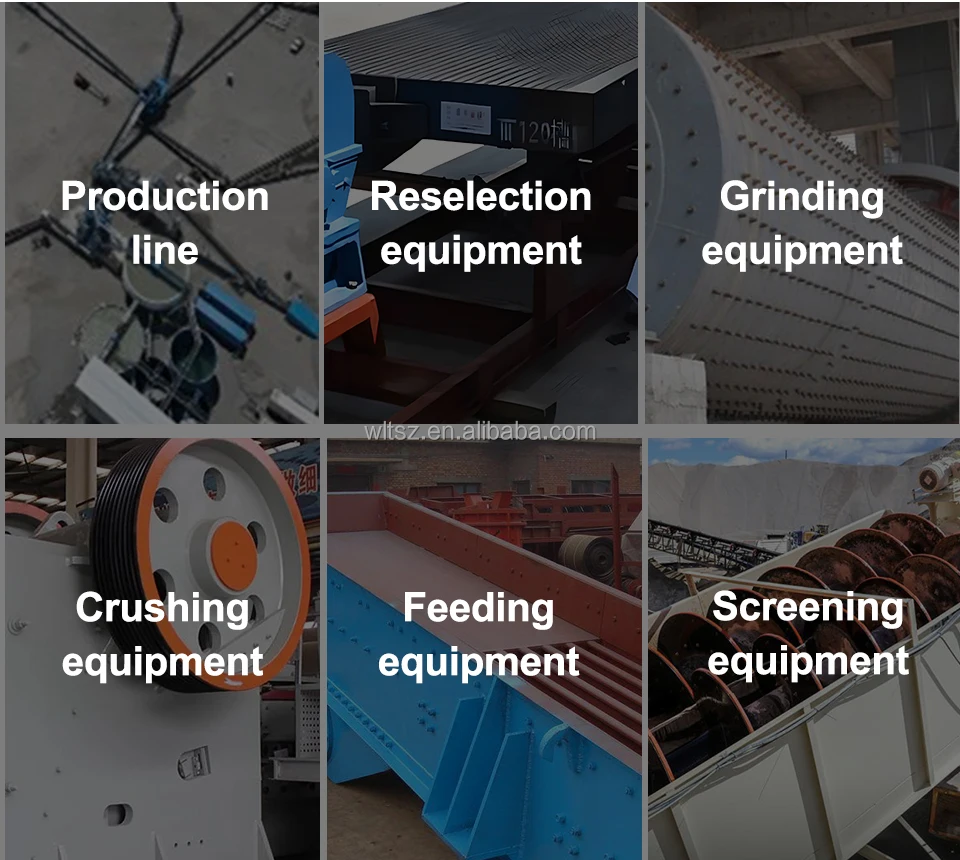

Product classification

Manufacturing

Certifications

24/7/365 Service