Fully Automatic Plastic PET Bottle Crushing Washing Recycling Line With Label Remover

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Jiangsu, China |

|---|---|

| brand name | REGULUS |

| automatic grade | Automatic |

| equipment list | Dewatering Machine, Frication Washer, Floating Washing Tank, Label Separator, Trommer, Pre-washer, Bale Opener, Hot Air Dryer |

| max.production capacity (kg/h) | 2000 |

| voltage | 380V/3 Phrase/50HZ or customized |

| dimension(l*w*h) | According to model |

| power (kw) | 160 |

| weight (t) | 10 |

| warranty | 1 Year |

| key selling points | Competitive Price |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump, washer, dryer, crusher |

| After-sales Service Provided | Field installation,commissioning and training |

| Raw material | Waste PET Bottle |

| Material Processed | Crushing-washing-drying |

| Final Product | Clean PET Flakes(16-18mm,customized) |

| Model | 300/500/1000/2000/3000/6000KG/H |

| Material of washing part | 304 Stainlss steel |

| Material of Crusher Blades | D2/SKD-11 |

| Colour of Machine | Customized |

| Electric Control Panel | Siemens Brand |

| Marketing Type | New Product 2024 |

| Condition | New |

| Plastic Type | PET |

| Machine Type | PET Bottle Washing Line |

| Applicable Industries | hotels, Building Material Shops, Manufacturing Plant, Machinery Repair Shops |

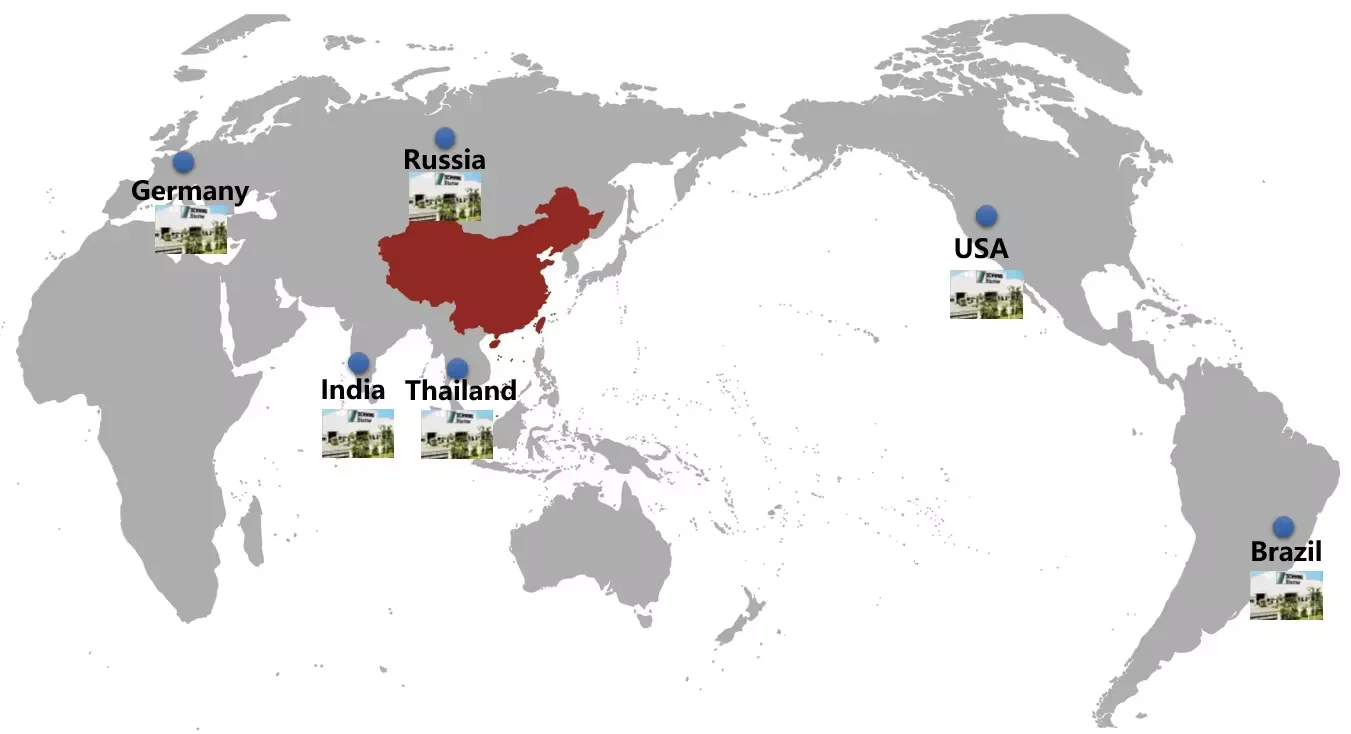

| Showroom Location | Canada, Egypt, Turkey, United Kingdom, United States, Germany, Brazil, Peru |

| Warranty of core components | 1 Year |

| Application | PET bottles |

| Production Capacity (kg/h) | 500 - 2000 |

Product Detail

Pre-Processing Part | Pre-processing modular is freely consists of bale breaker, pre-washer, metal detector, label remover, and some other equipments.It provides pre-treatment for the raw material. | ||||||

Size Reduction Part | Large materials are processed into small pieces, which improves the washing result and makes the final product easy to packing. | ||||||

Washing Part | Dust, glue, label, oil and other impurities can be removed highly effective by washing. This part combines floating washer, hot washer, friction washer. | ||||||

Drying Part | Drying treatment is used to remove the moisture in the material with low packing density. | ||||||

Sorting Part | Many other technology is used to separate material and color to purify and sort products. | ||||||

MODEL | Dimension(m²) | Installed power(KW) | Productivity(kg/h) | Water consumption(m³/h) |

PET-500 | 350 | 180 | 500 | 2 |

PET-1000 | 700 | 288 | 1000 | 4 |

PET-2000 | 1000 | 380 | 2000 | 6 |

PET-3000 | 1500 | 380 | 2000 | 8 |