Adjustable Stroke Mechanical Power Press Custom Digital Stamping Machine for Metal Sheet Punching Equipment for Metal Stamping

Other recommendations for your business

Contact us

Quik Detail

| cnc or not | Normal |

|---|---|

| machine type | Punching Machine |

| slide stroke (mm) | 150 |

| power source | Mechanical |

| place of origin | Shandong, China |

| brand name | BESCOMT |

| voltage | 380v |

| dimension(l*w*h) | 900*665*1658 |

| motor power (kw) | 1.1 |

| model number | J23/J21 Stroke adjustable |

| weight (t) | 1 |

| key selling points | Competitive Price |

| warranty | 2 years |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | Pump, motor, Pressure vessel |

| Color | customisable |

| Keyword | mechanical punching machine |

| Product name | Mechanical presses with adjustable stroke |

| Name | Mechanical Press Machine |

| Power type | Mechanical |

| Advantage | High Efficiceny |

| Brand | BESCOMT |

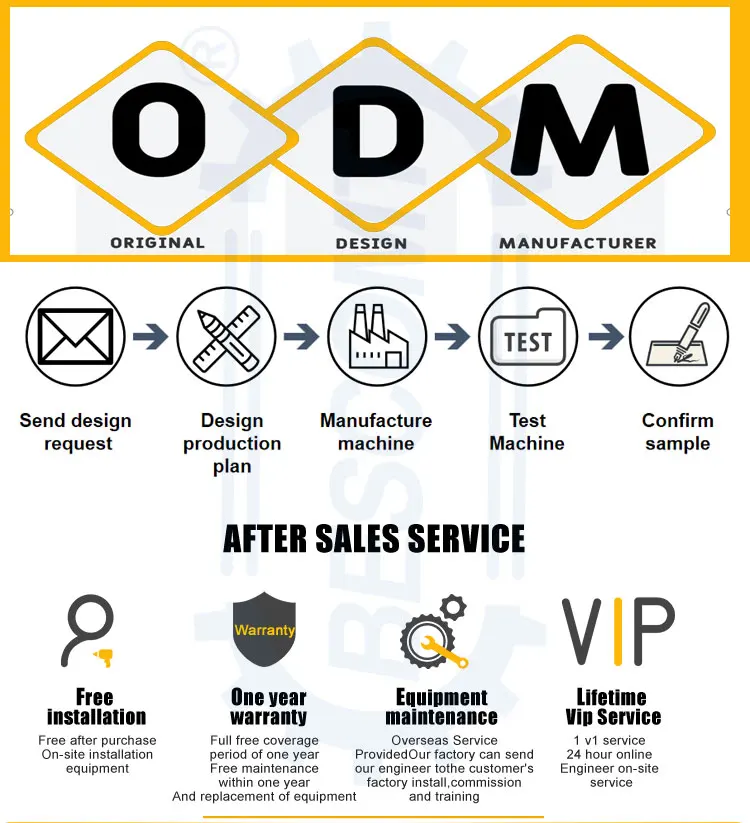

| After Sale Service | overseas service provide |

| Type | stroke adjustable |

| Function | Make Eyelet |

| Condition | New |

| Applicable Industries | hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Algeria, Sri Lanka, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia |

| Warranty of core components | 1 Year |

| Marketing Type | New Product 2024 |

Product Detail

Specifications | J21/J23-10 | J21/J23-16 | J21/J23-25 | J21/J23-40 | J21/J23-63 | J21/J23-80 | J21/J23-100 | J21/J23-125 | ||

Nominal Capacity (kn) | 100 | 160 | 250 | 400 | 630 | 800 | 1000 | 1250 | ||

Nominal stroke(mm) | 2 | 2 | 2.5 | 6 | 6 | 7 | 7 | 8 | ||

Slideing stroke(mm) | 45 | 55 | 65 | 90 | 110 | 120 | 140 | 150 | ||

Max Die Set height(mm) | 180 | 200 | 270 | 320 | 360 | 440 | 480 | 500 | ||

Die height adjustment(mm) | 35 | 45 | 55 | 65 | 80 | 90 | 100 | 100 | ||

Thorat Depth(mm) | 130 | 160 | 200 | 250 | 260 | 350 | 380 | 390 | ||

Distance Between Uprights(mm) | 180 | 220 | 270 | 340 | 350 | 450 | 560 | 550 | ||

Side Bottom Size(mm) | 170*150 | 200*180 | 250*220 | 300*260 | 300*260 | 460*360 | 540*480 | 540*480 | ||

Bolster Area(mm) | 370*240 | 450*300 | 560*370 | 700*460 | 760*480 | 960*650 | 1080*710 | 1090*720 | ||

Presses Dimension(L*W*H) | 900*665*1658 | 1150*847*1910 | 1345*950*2130 | 1721*1335*2488 | 1810*1350*2740 | 2060*1715*3290 | 2404*1790*3625 | 2504*1790*3715 | ||

Motor Power(kw) | 1.1 | 1.5 | 2.2 | 5.5 | 5.5 | 7.5 | 11 | 11 | ||

treatment, Black oxid;

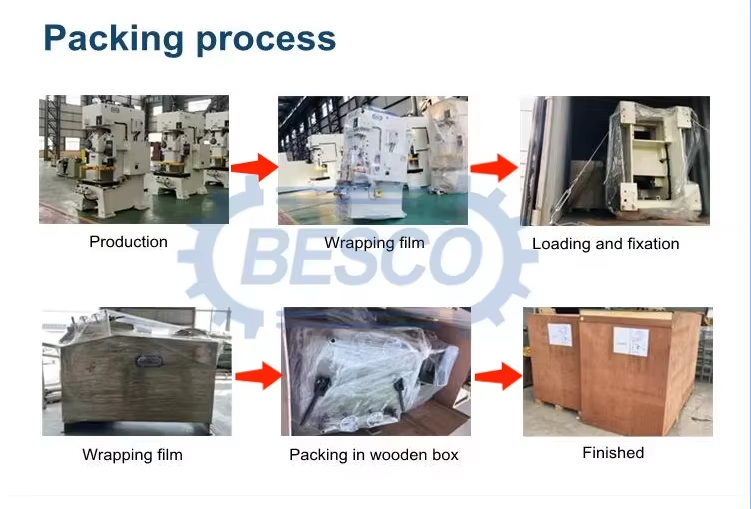

Delivery time:45 days after order

Packaging:Standard foreign trade wooden box export packaging

Warranty pertod:2 years

Technical service : available(online + offline)

Operation & maintenance manual(English Version)available

2.Can you supply the relevant documentation?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold

storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

5.Warranty Policy

The guarantee covers the main parts of the machine, excluding wearing parts. PARTS DELIVERY Within 5 days by DHL/ Fexed .During the warranty periodfree maintenance and replacement parts available if any quality problem under regular operation.(except for improper operation or man-made damage) .