DIN 338 5pcs 1mm 2.4mm 3.2mm 4.9 M35 Cobalt Titanium Metal Drill Bit HSS 4mm HSS Twist Drill Bits for Metal Drilling

US $0.15-0.50 / piece

10 piece(s)Minimum order

customized support:

OEM, ODM

place of origin:

Guangdong, China

brand name:

BWIN

model number:

Standard size

drill type:

Twist Drill Bit

use:

Metal Drilling

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| customized support | OEM, ODM |

|---|---|

| place of origin | Guangdong, China |

| brand name | BWIN |

| model number | Standard size |

| drill type | Twist Drill Bit |

| use | Metal Drilling |

| working length (mm) | 100 |

| finish | Other, Black Oxide, Amber Color |

| Product name | HSS M35 Cobalt Twist Drill Bit |

| Material | HSS Cobalt 5% |

| Shank | Straight Shank |

| Process | Fully Ground |

| Standard | DIN 338 |

| Usage | Metal/ HSS drilling |

| Package | 5 pcs/10 pcs in plastic box |

| Shipment | As your requirement |

Product Detail

Procuct Name | HSS-Co Twist Drill bit |

Material | M35, M2, HSS 4241, HSS 4341 |

Process | Roll forged, fully ground, milled |

Size | Normal standard: 0.2~20mm / or as your requirement. |

Flute Type | Type N, Right Hand Cutting |

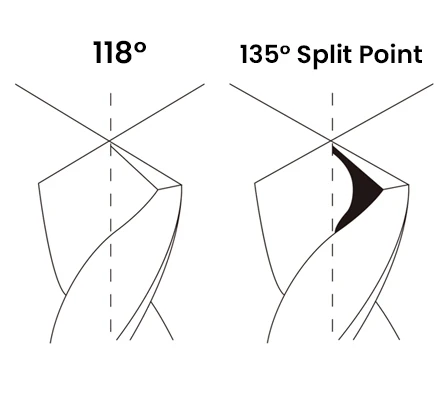

Point Angle | 118 Degree, 135 Degree |

Surface Finish | Amber Color, Black Oxide, Black & White, Gray & Bright, Bright, TiN Coated |

Usage | Suitable for drilling all kinds metal |

Package | 5pcs/10pcs in Plastic Box. |

(1) Heavy-duty construction for drilling in tough, high-tensile and work-hardening materials under extreme operation conditions. (2)Manufactured from premium 5% cobalt high speed steel increasing hot hardness and extending drill wear life. (3)135°split-point is self-centering for reduced thrust and easier penetration (4)Ideal for drilling hard material such as stainless steel. |

Drill points between normal 118°and 135° split point:

1. 118°point angles are used primarily in softer material such as mild steels and cast irons.

2. 135°split point should be used to cut harder steel materials and especially in deep holes over 4 times the drill diameter. With a 135°split point, cutting harder materials will produce thicker chips, minimizing work hardening of the cavity short.

The length of the lips on a 135°split point, measured from the axis to the cuter corners, is relativity short. This enables quicker penetration into the workpiece and reduces thrust and abrasion along the cutting edges.

3. When repointing a standard 118°point to 135°,make a lip correction to reduce the hook of the cutting face.

2. 135°split point should be used to cut harder steel materials and especially in deep holes over 4 times the drill diameter. With a 135°split point, cutting harder materials will produce thicker chips, minimizing work hardening of the cavity short.

The length of the lips on a 135°split point, measured from the axis to the cuter corners, is relativity short. This enables quicker penetration into the workpiece and reduces thrust and abrasion along the cutting edges.

3. When repointing a standard 118°point to 135°,make a lip correction to reduce the hook of the cutting face.

The Key cutting products we selling as below | ||||||

◆ Carbide inserts ◆ Solid Carbide End Mills ◆ Turning Bar Tool ◆ Face Milling Tool | ◆ Drills & Reamers & Thread Cutters & Burrs ◆ Thread Tapper Tool ◆ CNC Chuck & Adapter ◆ Precision Tool Vise ◆ Other Accessories. | |||||

DIN338 Parallel shank twist drills

D(mm) | L1 | L | D(mm) | L1 | L | D(mm) | L1 | L |

0.2 | 2.5 | 19 | 5.3 | 52 | 86 | 10.4 | 87 | 133 |

0.3 | 3 | 19 | 5.4 | 57 | 93 | 10.5 | 87 | 133 |

0.4 | 5 | 20 | 5.5 | 57 | 93 | 10.6 | 94 | 142 |

0.5 | 6 | 22 | 5.6 | 57 | 93 | 10.7 | 94 | 142 |

0.6 | 7 | 24 | 5.7 | 57 | 93 | 10.8 | 94 | 142 |

0.7 | 9 | 28 | 5.8 | 57 | 93 | 10.9 | 94 | 142 |

0.8 | 10 | 30 | 5.9 | 57 | 93 | 11 | 94 | 142 |

0.9 | 11 | 32 | 6 | 57 | 93 | 11.1 | 94 | 142 |

1 | 12 | 34 | 6.1 | 63 | 101 | 11.2 | 94 | 142 |

1.1 | 14 | 36 | 6.2 | 63 | 101 | 11.3 | 94 | 142 |

1.2 | 16 | 38 | 6.3 | 63 | 101 | 11.4 | 94 | 142 |

1.3 | 16 | 38 | 6.4 | 63 | 101 | 11.5 | 94 | 142 |

1.4 | 18 | 40 | 6.5 | 63 | 101 | 11.6 | 94 | 142 |

1.5 | 18 | 40 | 6.6 | 63 | 101 | 11.7 | 94 | 142 |

1.6 | 20 | 43 | 6.7 | 63 | 101 | 11.8 | 94 | 142 |

1.7 | 20 | 43 | 6.8 | 69 | 109 | 11.9 | 101 | 151 |

1.8 | 22 | 46 | 6.9 | 69 | 109 | 12 | 101 | 151 |

1.9 | 22 | 46 | 7 | 69 | 109 | 12.1 | 101 | 151 |

2 | 24 | 49 | 7.1 | 69 | 109 | 12.2 | 101 | 151 |

2.1 | 24 | 49 | 7.2 | 69 | 109 | 12.3 | 101 | 151 |

2.2 | 27 | 53 | 7.3 | 69 | 109 | 12.4 | 101 | 151 |

2.3 | 27 | 53 | 7.4 | 69 | 109 | 12.5 | 101 | 151 |

2.4 | 30 | 57 | 7.5 | 69 | 109 | 12.6 | 101 | 151 |

2.5 | 30 | 57 | 7.6 | 75 | 117 | 12.7 | 101 | 151 |

2.6 | 30 | 57 | 7.7 | 75 | 117 | 12.8 | 101 | 151 |

2.7 | 33 | 61 | 7.8 | 75 | 117 | 12.9 | 101 | 151 |

2.8 | 33 | 61 | 7.9 | 75 | 117 | 13 | 101 | 151 |

2.9 | 33 | 61 | 8 | 75 | 117 | 13.1 | 108 | 160 |

3 | 33 | 61 | 8.1 | 75 | 117 | 13.2 | 108 | 160 |

3.1 | 36 | 65 | 8.2 | 75 | 117 | 13.3 | 108 | 160 |

3.2 | 36 | 65 | 8.3 | 75 | 117 | 13.4 | 108 | 160 |

3.3 | 36 | 65 | 8.4 | 75 | 117 | 13.5 | 108 | 160 |

3.4 | 39 | 70 | 8.5 | 75 | 117 | 13.6 | 108 | 160 |

3.5 | 39 | 70 | 8.6 | 81 | 125 | 13.7 | 108 | 160 |

3.6 | 39 | 70 | 8.7 | 81 | 125 | 13.8 | 108 | 160 |

3.7 | 39 | 70 | 8.8 | 81 | 125 | 13.9 | 108 | 160 |

3.8 | 43 | 75 | 8.9 | 81 | 125 | 14 | 108 | 160 |

3.9 | 43 | 75 | 9 | 81 | 125 | 14.5 | 114 | 169 |

4 | 43 | 75 | 9.1 | 81 | 125 | 15 | 114 | 169 |

4.1 | 43 | 75 | 9.2 | 81 | 125 | 15.5 | 120 | 178 |

4.2 | 43 | 75 | 9.3 | 81 | 125 | 16 | 120 | 178 |

4.3 | 47 | 80 | 9.4 | 81 | 125 | 16.5 | 125 | 184 |

4.4 | 47 | 80 | 9.5 | 81 | 125 | 17 | 125 | 184 |

4.5 | 47 | 80 | 9.6 | 87 | 133 | 17.5 | 130 | 191 |

4.6 | 47 | 80 | 9.7 | 87 | 133 | 18 | 130 | 191 |

4.7 | 47 | 80 | 9.8 | 87 | 133 | 18.5 | 135 | 198 |

4.8 | 52 | 86 | 9.9 | 87 | 133 | 19 | 135 | 198 |

4.9 | 52 | 86 | 10 | 87 | 133 | 19.5 | 140 | 205 |

5 | 52 | 86 | 10.1 | 87 | 133 | 20 | 140 | 205 |

5.1 | 52 | 86 | 10.2 | 87 | 133 | |||

5.2 | 52 | 86 | 10.3 | 87 | 133 |

Other Products

Our Company

COMPANY PROFILE

Shenzhen BWiN Precision Tools Co.,Ltd. is a main professional supplier in CNC Carbide inserts, Turning tools and Milling tools, BWiN manufacture with integration of R&D, Design and Sales. We insists the principles of "High quality, Competitive price and Excellent service."

BWiN manufacture has over 1500 square meter factory area and storehouse. We are leading OED&ODM manufacture many years of experience in this filed. BWiN have various kinds of productc and they are 70% for expert. Our customers are from all over the world, such as North America, Europe, South America, the Middle east, East Asia and Africa. The quality control standards are based on ISO9001 certifications. BWiN relies on advanced automatic machining center and complete testing testing method, control all aspects of production and operation according to the standard process. We have an outstanding team of designers to continuously launch innovative product design, in order to meet the needs of the international marked. Welcome send inquiry to us, we will provide high quality products and excellent service for you!

BWiN manufacture has over 1500 square meter factory area and storehouse. We are leading OED&ODM manufacture many years of experience in this filed. BWiN have various kinds of productc and they are 70% for expert. Our customers are from all over the world, such as North America, Europe, South America, the Middle east, East Asia and Africa. The quality control standards are based on ISO9001 certifications. BWiN relies on advanced automatic machining center and complete testing testing method, control all aspects of production and operation according to the standard process. We have an outstanding team of designers to continuously launch innovative product design, in order to meet the needs of the international marked. Welcome send inquiry to us, we will provide high quality products and excellent service for you!

FAQ

1. Are you manufacturer or trading company?

We are professional manufacturer with more than 10 years experience in this field.

2. How to place an order?

1.Fill your Order List in our online Inquiry System.

2.Directly contact our salesperson by E-mail / Skype / Whats App

We will make a feedback to you ASAP after receive your order list.

3. What is your payment terms?

T/T, Paypal, Western Union, Alibaba assurance for different circumstances.

4. What's your delivery way?

Express delivery, DHL, TNT, FEDEX , EMS, air shipping, sea shipping are available for your request.

5. Do you offer OEM?

Yes, we do. We have laser machine lasering your logo and tool specification on the body of tools. Also, we can print customized on plastic boxes.

6. How about the delivery time?

Usually delivery time is 2~3 days after receiving the advance payment. For the customized product, 7-10 days after receiving the advance payment.