High Precision Extrusion Press Aluminum Extrusion Machine for Aluminum Tube

US $39,599.00-76,000.00 / set

1 set(s)Minimum order

place of origin:

Liaoning, China

brand name:

Jiuying

machine type:

Aluminum Product Extrusion Line

weight (kg):

25000

video outgoing-inspection:

Provided

machinery test report:

Provided

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Liaoning, China |

|---|---|

| brand name | Jiuying |

| machine type | Aluminum Product Extrusion Line |

| weight (kg) | 25000 |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | motor, heat exchanger |

| warranty | 1 Year |

| key selling points | Competitive Price |

| Machine Type | Extrusion Press |

| Condition | New, New |

| Weight | 25000kg |

| Warranty of core components | 1 Year, 1 Year |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Building Material Shops, Home Use |

| Brand Name | Jiuying |

| Control system | Full-automatic |

| After Warranty Service | Video technical support |

| Showroom Location | Argentina, Chile, United Kingdom, United States, Brazil |

| Marketing Type | New Product 2024 |

Product Detail

Product description

Features of Aluminum Extrusion Press

1. Structure

The machine has a four-column horizontal structure with a top-mounted oil tank. Its structure is compact and easy to assemble or disassemble.

2. Extrusion Process

There are two extrusion processes: following needles and fixed needles. Our machine can meet the extrusion requirements of different pipe diameters.

3. Electronic Component

We use PLC control and can do man-machine interface real-time monitoring.

4. Hydraulic System

Hydraulic system adopts large flow plug valve, stable performance, large flow, and low-temperature rise.

5. Locate Mode

The movable beam adopts four points positioning, and the center can be adjusted. It is convenient, safe, and rapid.

The machine has a four-column horizontal structure with a top-mounted oil tank. Its structure is compact and easy to assemble or disassemble.

2. Extrusion Process

There are two extrusion processes: following needles and fixed needles. Our machine can meet the extrusion requirements of different pipe diameters.

3. Electronic Component

We use PLC control and can do man-machine interface real-time monitoring.

4. Hydraulic System

Hydraulic system adopts large flow plug valve, stable performance, large flow, and low-temperature rise.

5. Locate Mode

The movable beam adopts four points positioning, and the center can be adjusted. It is convenient, safe, and rapid.

Range of Work

At present, copper and aluminum profile extrusion machines have been widely used in construction, electronics, automobiles, aerospace, machine manufacturing, and other fields.

In actual production, the application rate of copper-aluminum profile extrusion machines is constantly increasing, which can meet the needs of various industries.

Product parameter

TECHNICAL PARAMETERS FOR ALUMINUM EXTRUSION PRESS | ||||||||||

Model | Extruding Speed (mm/s) | Rated Extrusion Force | Fixed Work Stress (MPa) | Main Motor Power (KW) | ||||||

XJ-630 | 40 | 6300KN | 700UST | 21 | 75×3 | |||||

XJ-800 | 50 | 8000KN | 880UST | 21 | 132×3 | |||||

XJ-1000 | 40 | 10000KN | 1100UST | 21 | 132×3 | |||||

XJ-1250 | 50 | 12500KN | 1350UST | 21 | 132×4 | |||||

XJ-1630 | 40 | 16300KN | 1800UST | 21 | 132×5 | |||||

XJ-1800 | 40 | 18000KN | 2000UST | 21 | 132×6 | |||||

XJ-2200 | 40 | 22000KN | 2420UST | 21 | 132×7 | |||||

XJ-2500 | 40 | 25000KN | 2750UST | 21 | 132×8 | |||||

Mechanical Part

The mechanical part is composed of base, prestressed frame type tension column, front beam, movable beam, X-shaped oriented extrusion cylinder seat, extrusion shaft, ingot feeding mechanism, residual material separation shear, sliding die base, etc.

Hydraulic Part

The hydraulic system is mainly composed of master cylinder, side cylinder, locking cylinder, perforated cylinder, large-capacity axial piston variable pump, electro-hydraulic ratio servo valve (or electro-hydraulic proportional regulating valve), position

sensor, oil pipe, oil tank and various hydraulic pressure switch composition.

sensor, oil pipe, oil tank and various hydraulic pressure switch composition.

Electrical Part

The electrical part is mainly composed of power supply cabinet, operation console, PLC programmable controller, upper industrial control machine and display screen.

Application Field

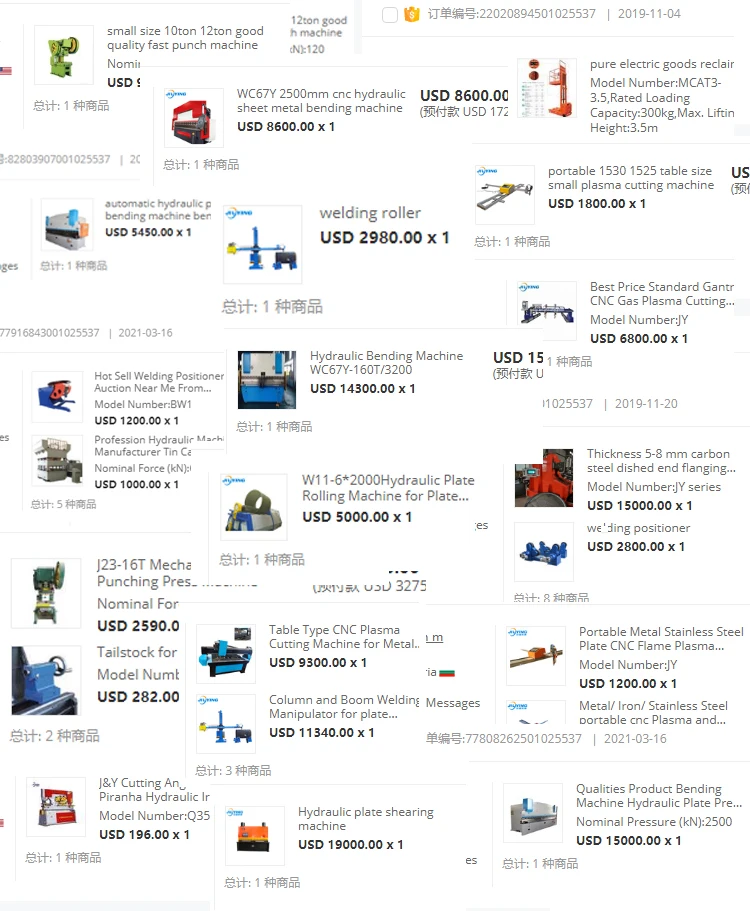

Our order and visitors

Since its establishment, Dalian J&Y Machinery Co., Ltd. has been adhering to the enterprise spirit of "pursuing excellence and exceeding expectations", insisting on improving user satisfaction and its own service level, receiving customers with high-level and convenient services, and devoting This kind of demand has won unanimous praise from customers.

Products Recommended

Company Profile

Company Information

Dalian J&Y Machinery Equipment Co., Ltd. was established in 2012.We are an enterprise specializing in the development and sales of CNC machine tools and automatic welding equipment. We mainly sell Production lines, casting equipment, sheet metal processing equipment, welding equipment and so on.

Dalian J&Y Machinery Equipment Co., Ltd. covers an area of 66,600 square meters with a total investment of more than 150 million yuan. There are more than 120 employees, including 30 professional and technical personnel and 10 personnel with intermediate and senior titles. The company has excellent equipment, strong technical force, advanced manufacturing technology,complete testing methods and perfect quality system. There are more than 150 main equipment, 5 automated and semi-automated production lines, with an annual production capacity of 50,000 sets.

We adhere to the principle of "customers are the first priority" and continue to pursue innovation and development. We also strive to develop high-tech products to meet the needs of customers in different industries. Our goal is to become the most competitive enterprise in the field of providing automation products and cutting and welding equipment industry services. In short, join us and create a better future together, because J&Y can become your most reliable business partner!

Packaging & Shipping

FAQ

Q1.What is our main product ?

A1: Our company is a professional sheet metal processing machinery by JIUYING.HEAVY MACHINE CO.,LTD. in 1988. Concentrate on four column press machine, embossing door press machine, bending machine, shearing machine, cnc plasma cutting machine, rolling machine, punching machine, hydraulic ironworker, welding equipment.

All these machine will be solved for the tank, pan, trolley, ect.

Q2.When can I get the price ?

A2:We usually offer the quotation within 8hours, For urgent offer, please contact with us for special.

Q3.What is the Trade Term?

A3: We accept Ex-work factory , FOB Dalian, CNF or CIF, as your requirement.

Q4.How long is our Production leading time?

A4: It depends on type of equipment.

We often deliver the goods within 35days.

Q5.What is the Payment term?

A5: By T/T before shipment or By L/C at sight.

Q6. During shipping, if there is a damage to products, how do you get replacement?

A6: Firstly, we should investigate the reason cause the damage. At the same time, we will claim for the insurance by ourselves or assist the buyer.

Secondly we will send the replacement to the buyer. The responsible person for above damage will take charge of the cost of the replacement.

Q7. What are your terms of packing?

A7: Packing: export worthy package suitable for container transportation.

Wooden case, iron pallet, plastic film ect.

Q8. Do you test all your goods before delivery?

A8: Yes, we have 100% test before delivery.

Q9: Where is your factory located?

A9: Our factory is located in Dalian, Liaoning province.

Q10: What is your warranty?

A10: Warranty: 24 months after commercial running or 18months from the date of shipment, subject to the earlier expiry.

Q11: Can you arrange thirty party pre-shipment inspection?

A11: Pre-shipment inspection: Supplier’s pre-shipment inspection is Final; pre-shipment inspection by third Party on buyers cost.

Q12:Can we do our OEM logo?

A12:Yes, for the products with drawing supplied by you, we of course apply your logo

A1: Our company is a professional sheet metal processing machinery by JIUYING.HEAVY MACHINE CO.,LTD. in 1988. Concentrate on four column press machine, embossing door press machine, bending machine, shearing machine, cnc plasma cutting machine, rolling machine, punching machine, hydraulic ironworker, welding equipment.

All these machine will be solved for the tank, pan, trolley, ect.

Q2.When can I get the price ?

A2:We usually offer the quotation within 8hours, For urgent offer, please contact with us for special.

Q3.What is the Trade Term?

A3: We accept Ex-work factory , FOB Dalian, CNF or CIF, as your requirement.

Q4.How long is our Production leading time?

A4: It depends on type of equipment.

We often deliver the goods within 35days.

Q5.What is the Payment term?

A5: By T/T before shipment or By L/C at sight.

Q6. During shipping, if there is a damage to products, how do you get replacement?

A6: Firstly, we should investigate the reason cause the damage. At the same time, we will claim for the insurance by ourselves or assist the buyer.

Secondly we will send the replacement to the buyer. The responsible person for above damage will take charge of the cost of the replacement.

Q7. What are your terms of packing?

A7: Packing: export worthy package suitable for container transportation.

Wooden case, iron pallet, plastic film ect.

Q8. Do you test all your goods before delivery?

A8: Yes, we have 100% test before delivery.

Q9: Where is your factory located?

A9: Our factory is located in Dalian, Liaoning province.

Q10: What is your warranty?

A10: Warranty: 24 months after commercial running or 18months from the date of shipment, subject to the earlier expiry.

Q11: Can you arrange thirty party pre-shipment inspection?

A11: Pre-shipment inspection: Supplier’s pre-shipment inspection is Final; pre-shipment inspection by third Party on buyers cost.

Q12:Can we do our OEM logo?

A12:Yes, for the products with drawing supplied by you, we of course apply your logo