KERUI Refractory 1050 1260 1400 1600 ℃ 96 128kg / M3 Insulation Ceramic Fiber Blanket for Industrial Boiler

US $8.00-23.00 / roll

100 roll(s)Minimum order

Place of Origin:

Henan, China

Brand Name:

KERUI

Model Number:

HAZ

Grade:

HAZ (High Aluminum Zirconium)

Working Temperature:

1460-1600℃

Density (kg/m³ ):

128

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Place of Origin | Henan, China |

|---|---|

| Brand Name | KERUI |

| Model Number | HAZ |

| Grade | HAZ (High Aluminum Zirconium) |

| Working Temperature | 1460-1600℃ |

| Density (kg/m³ ) | 128 |

| Al2O3 | 44% |

| AL2O3+SIO2 | 96% |

| Bulk & Density | 96-160g/cm3 |

| Fe2O3 | <1.2% |

| Size | Standard Size: 7200*610*6-60; Customized Sizes |

| Certificate | ISO9001 CE MSDS |

Product Detail

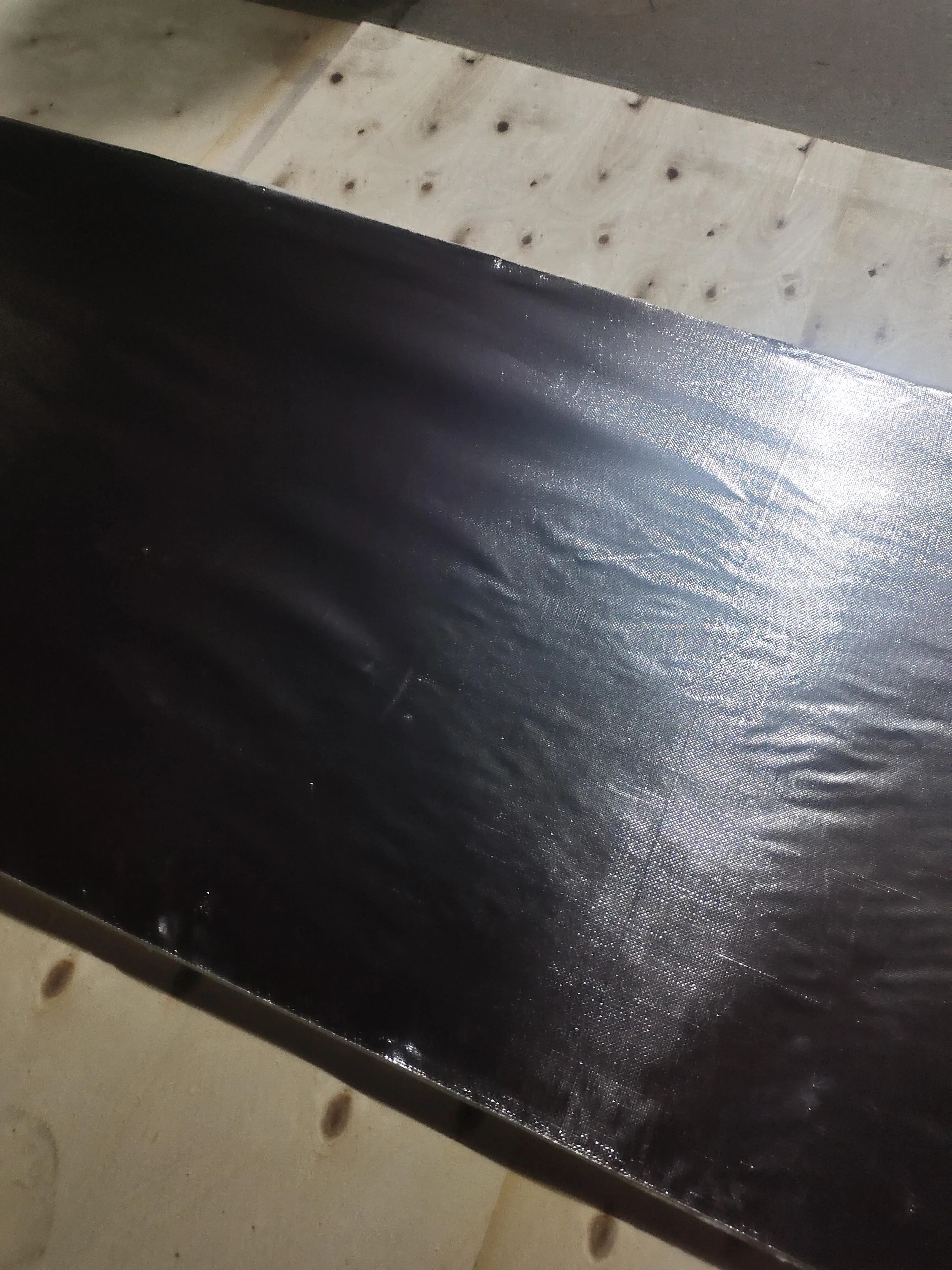

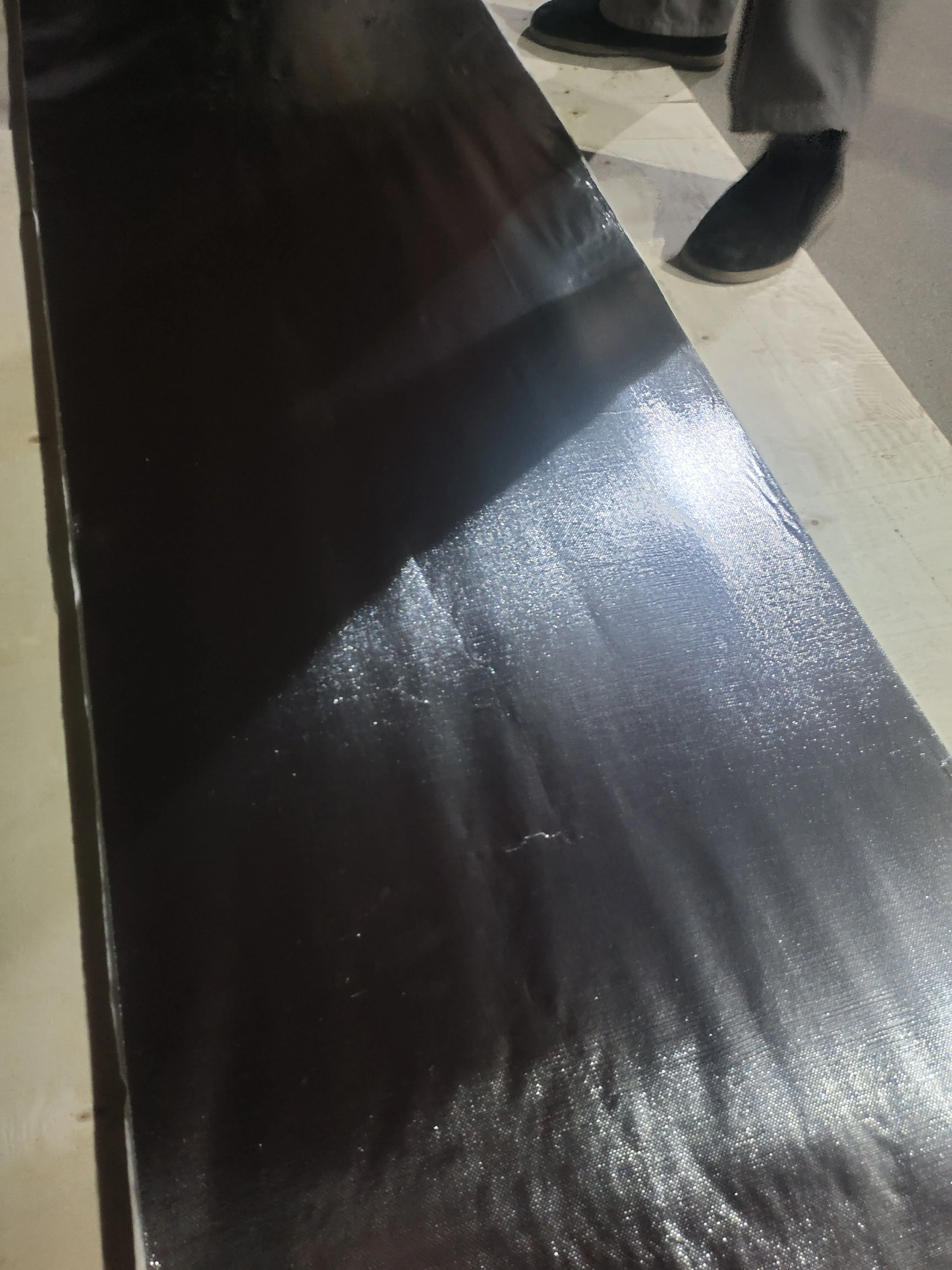

What's Ceramic Fiber Blanket?

Ceramic fiber insulation blanket is a kind of continuous cotton flat fiber blanket made of high-purity raw materials, which is formed by high-temperature melting, spinning, and needle punching. It is a pure inorganic fiber material, which can be divided into ordinary type (1100°C), standard type (1260°C), high-temperature type (1400°C), and ultra-high temperature type (1600°C) according to the classification temperature.

Features:

Lightweight and High Temperature Resistant: Ceramic fiber blanket has excellent heat resistance and can be used for a long time in high-temperature environments.

Good Thermal Stability: Ceramic fiber blankets can maintain good strength and toughness in neutral, oxidizing, and reducing atmospheres.

Low Thermal Conductivity: The low thermal conductivity of ceramic fiber blanket makes it excellent in thermal insulation.

Non-brittle Material: Compared with traditional brittle materials, ceramic fiber blankets have better toughness and are not easy to break.

Easy to Process: Ceramic fiber blanket can be sheared and bent as needed, and the construction is convenient.

Excellent Anti-wind Erosion Performance: The integrity of the material can be maintained even in harsh environments.

Parameters:

Item | Common Type | Standard Type | High Purity Type | High Alumina Type | Zirconium Containing Type | ||||

Classification Temperature, ℃ | 1050 | 1260 | 1260 | 1350 | 1430 | ||||

Service Temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 | ||||

Bulk & Density, kg/m³ | 96-128 | 96-128 | 96-128 | 128-160 | 128-160 | ||||

Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) | -3 (1250℃) | -3 (1350℃) | ||||

Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) | 0.09 (400℃) 0.176 (800℃) 0.22 (1000℃) | 0.132 (600℃) 0.22 (1000℃) | 0.76 (800℃) 0.20 (1000℃) | ||||

Strength of Extension, Mpa | 0.08-0.12 | ||||||||

Al2O3, % | 44 | 46 | 47-49 | 52-55 | 39-40 | ||||

Al2O3+SiO2, % | 96 | 97 | 99 | 99 | - | ||||

Al2O3+SiO2+ZrO2, % | - | - | - | - | 99 | ||||

ZrO2, % | - | - | - | - | 15~17 | ||||

Fe2O3, % | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | ||||

Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | ||||

Size, mm | Standard Size: 7200*610*6-60; Customized | ||||||||

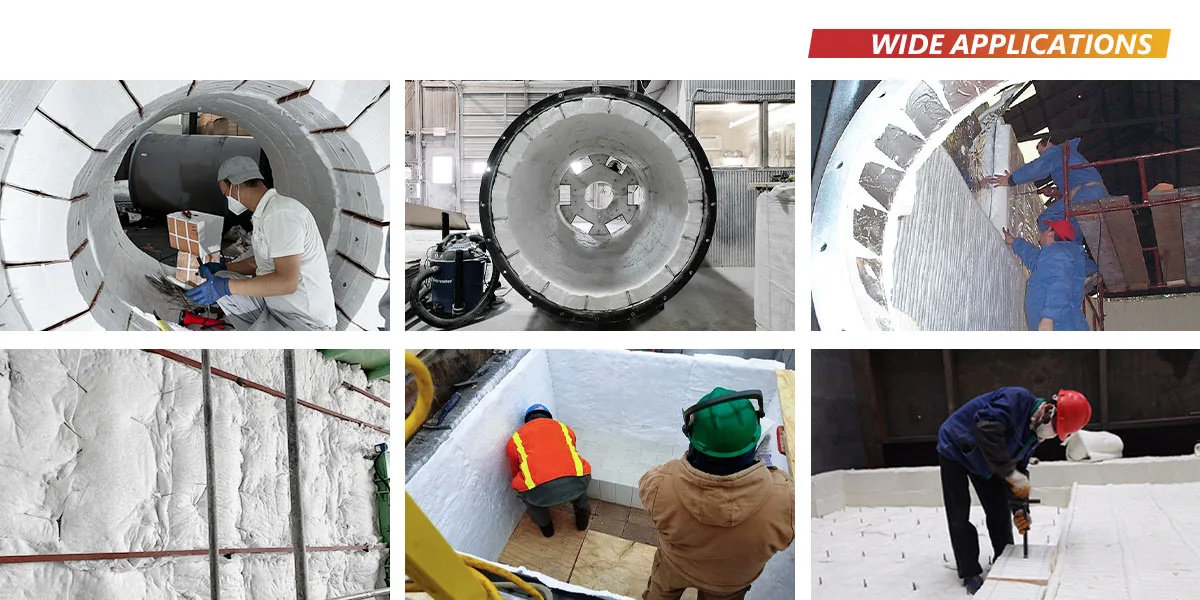

What's the Uses of Ceramic Fiber Blanket?

Ceramic fiber blanket is a high-temperature resistant insulation material. It is widely used in many fields due to its excellent thermal insulation performance and lightweight.

Applications of Ceramic Fiber Blankets:

Insulation of Industrial Kilns and High-temperature Equipment:

The Ceramic fiber blanket is often used as lining material for high-temperature kilns and heat treatment equipment in industries such as steel, glass, and ceramics. Its high-temperature resistance can effectively reduce heat loss and improve the energy efficiency of equipment.

Refractory Insulation Material:

In buildings and industrial facilities, ceramic fiber blankets are used as fireproof insulation materials, especially around walls doors windows that require fire protection, which can effectively prevent the spread of flames.

Automotive Industry:

Used for insulation and noise reduction of automobile exhaust pipes and muffler systems, ceramic fiber blankets can withstand high-temperature environments, prevent heat loss, and reduce noise pollution.

Power Equipment:

Ceramic fiber blankets are used for thermal insulation of boilers and heat exchangers in power plants, which can reduce heat loss and improve the working efficiency of equipment.

Chemical Equipment:

In the petrochemical industry, ceramic fiber blankets are used as insulation materials for pipes, reactors, and heating devices, which can effectively cope with high temperatures and corrosive environments.

Aerospace:

Used in thermal insulation protection systems for aircraft and spacecraft, ceramic fiber blankets can provide excellent thermal insulation performance under extremely high-temperature conditions to protect equipment from thermal damage.

Household Appliances:

In the internal insulation layer of some household appliances such as electric ovens, microwave ovens, water heaters, etc., ceramic fiber blankets can improve thermal insulation performance and reduce heat leakage.

The lightweight, high-temperature resistance, low thermal conductivity, and excellent thermal stability of ceramic fiber blankets make them an ideal choice for various high-temperature applications.

How to Construction?

Wrapping Method:

Generally, the wrapped blanket is required to be solid and free of gaps.

Posting Method:

The adhesive should be applied evenly and fully, and the blanket should be pressed tightly with a wooden trowel after it is pasted.

In short, ceramic fiber insulation blanket has become an ideal choice in the industrial field due to its excellent performance and wide application. Its lightweight, high-temperature resistance, low thermal conductivity, and other characteristics make it play an important role in the field of thermal insulation.

Email: sales@keruirefra.com

Cell/Online: +86 173 4499 8507

Why Choose Us?

Factory:

Zhengzhou Kerui Industrial Development Co., Ltd. is a branch of Zhengzhou Kerui (Group) Refractory Co., Ltd.. We provide all types of refractory products, including refractory bricks and materials, insulation bricks and materials, kiln shelves and new materials, etc. Kerui Refractory is located in the largest refractory industry zone: Chaohua Town, Xinmi City, Henan Province, China.Founded in 2004 with a registered capital of 81.8 million Yuan, Zhengzhou Kerui Refractory Material Co. , Ltd. is located in the refractory industry base of Chaohua town, Xinmi Province, After 20 year’s hard work and tenacious struggle , we walked out of a“Product oriented, service first” healthy and rapid development of the road, has developed into a Refractory R & D, production, sales, Product Technology Solutions, Project EPC general contracting services in one of the modern integrated enterprise group.

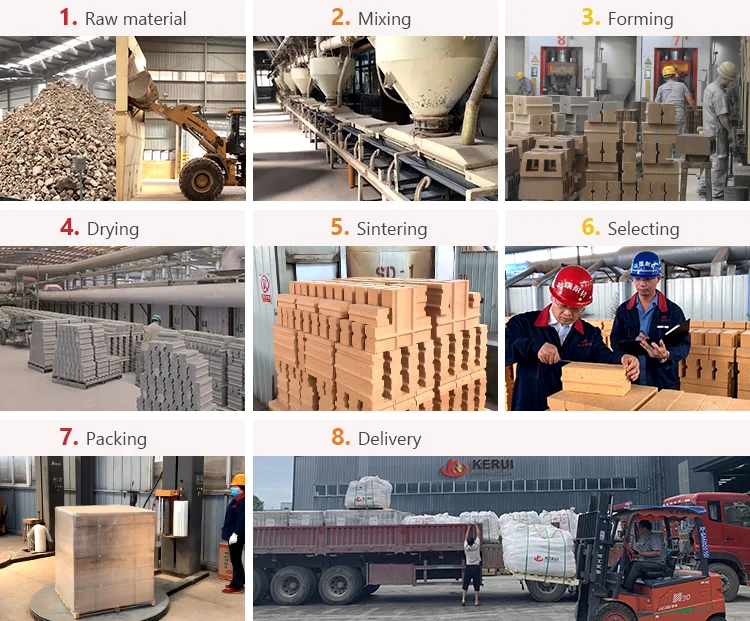

Flow of Production:

KERUI Teams:

Kerui has an exclusive R&D team, a professional sales team, an experienced technical guidance team, and a top after-sales service team for every customer.

Professional R&D Team

Kerui own 50000m² factory ,R&D、production、sales、delivery as one,fully equipped,own patents,support customization.

Professional Sales Team

Kerui has its own sales and service team, proficient in foreign languages, instant communication with customers and can solve customer problems at first time.

Professional Solutions

Kerui has EPC capability, can undertake customer projects, has professional technical experts, according to customer needs to develop the most perfect plan.

Professional After-sale Team

Kerui has its own professional after-sales team, once the customer has any technical problems, it can respond and solve within 1 hour.

Customer Visits:

Welcome to Kerui, our ingenious production base. We will show you Kerui's craftsmanship and innovative ideas. We have always adhered to the business philosophy of "quality first, customer first". Welcome everyone to experience our products and services up close. We will be your trusted partner. Welcome everyone to come here to find business opportunities and seek common development.

Partners:

KERUI refractory products have been exported to many countries such as Russia, Korea, Indonesia, Turkey,Egypt and South Africa etc.

Keeping long term cooperation with some world famous companies including RUSAL, ALBA, CHALCO, POSCO, PSM.

Keeping long term cooperation with some world famous companies including RUSAL, ALBA, CHALCO, POSCO, PSM.

What do Customers Say?

RUSAL Group of Russia:

“We are satisfied with refractory bricks and insulation bricks from Kerui Refractory. The appearance of these bricks is neat, the color is uniform, and the use experience is beyond imagination. More importantly, Kerui Refractory provides professional technical service for us, which saves our time and energy greatly.”

Hot Blast Stove of Kalugin:

“Among so many refractory brick suppliers, we choose Kerui Refractory. Refractory bricks bought from Kerui Refractory are uniform in size and have a long service life. We believe that we will carry out long-term cooperation with Kerui Refractories in the future.”