ZR BREW 20bbl 1000l 3-vessel Commercial Electric Stainless Steel Discount Brewing Equipment Brewhouse Beer Brewing Machine

1 piece(s)Minimum order

processing:

Fermenting Equipment

place of origin:

Shandong, China

brand name:

ZR BREW

processing types:

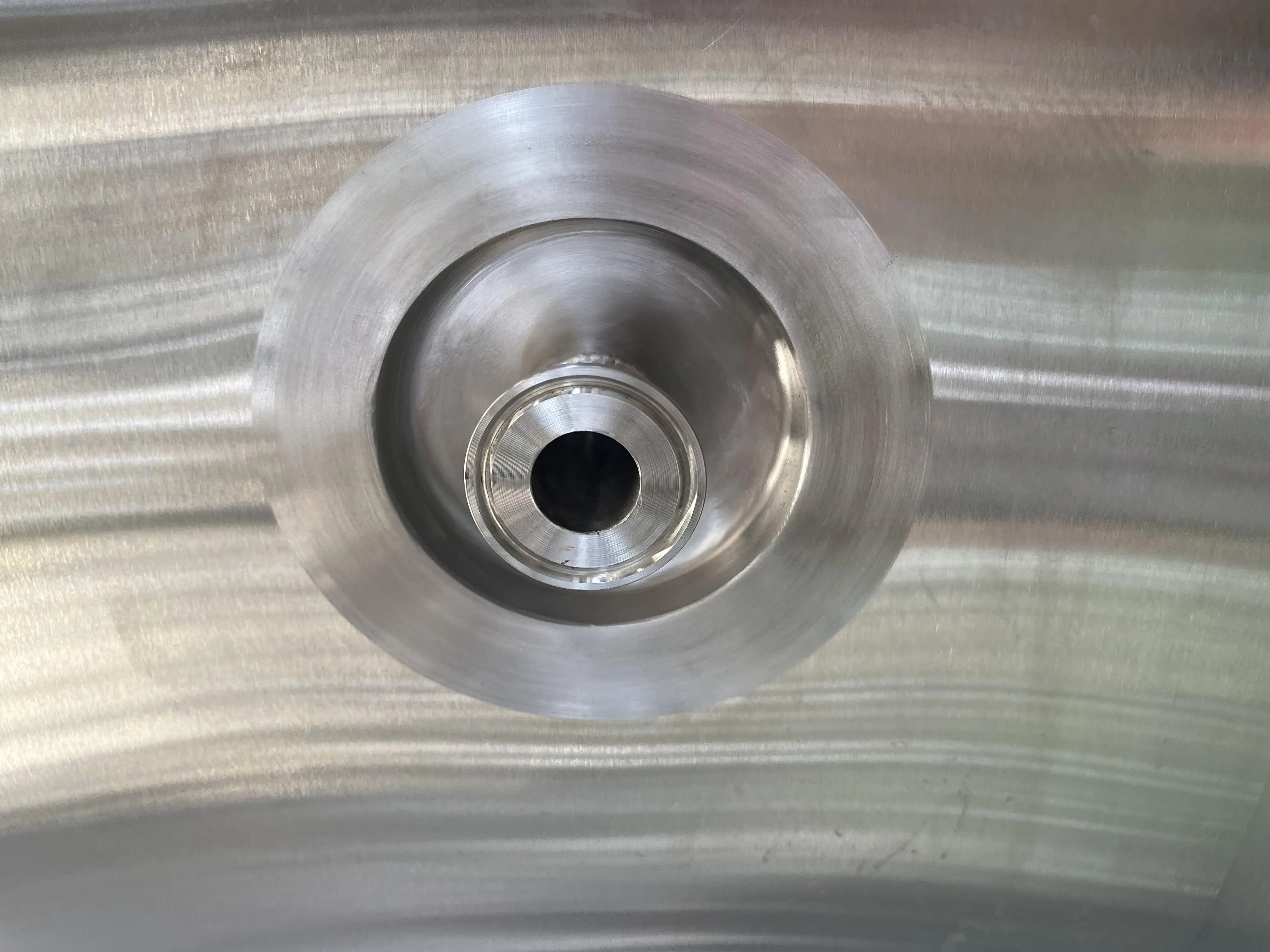

Beer

voltage:

Customizable

power(w):

Customizable

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| processing | Fermenting Equipment |

|---|---|

| place of origin | Shandong, China |

| brand name | ZR BREW |

| processing types | Beer |

| voltage | Customizable |

| power(w) | Customizable |

| dimension(l*w*h) | Customizable |

| weight | 1450 KG |

| warranty | 5 years |

| Machinery Capacity | 500L, 600L, 700L, 800L, 1000L, 1200L, 1500L, 1800L, 2000L |

| machinery test report | Provided |

| core components | Gearbox, motor, Gear, Pump, PLC |

| key selling points | High Productivity |

| video outgoing-inspection | Provided |

| Product Name | Stainless Steel beer brewing equipment |

| Material | Stainless Steel 304 |

| Capacity | 1000L |

| Inner jacket | 3.0mm |

| Outer jacket | 2.0mm |

| Insulation | Polyurethane/rockwool 80mm |

| Function | Brewing Beer |

| Polish Finish | 0.4μm |

| Application | Restaurants/Brewpub/Bars/Hotels/Brewing Plant |

| After-sales Service Provided | Overseas Service Provided |

| Applicable Industries | hotels, Manufacturing Plant, Food & Beverage Factory, Restaurant, Food Shop, Food & Beverage Shops |

| Showroom Location | Canada, United Kingdom, United States, France, Germany, India, Spain, Chile, Colombia, South Africa, Malaysia, Australia |

| Condition | New |

| Warranty of core components | 1 Year |

| Marketing Type | New Product 2023 |

Product Detail

Products Description

Brewing good beer requires good beer equipment. Whether you're brewing beer for your home, pub or brewery, ZR BREW can provide a turnkey solution for your yield needs. We have 1-vessel, 2-vessel, 3-vessel and 4-vessel brewing equipment. We have been adhering to the principle that the equipment is more energy-efficient and easier to operate, so as to save the greatest possible cost for your brewery operation. We also produce fermentation tanks and sake tanks.

Product Paramenters

1000L 3-vessel brewhouse | ||||

Production | 1000L/Batch,Up to 4 batches/day, up to 120T /month | Jacket | ||

Material | SUS304/SUS316 | SUS304 | ||

ombination method | 3-Vessel | 0.3 (45psi) | ||

Application | Restaurant /Bar /Hotel /Brewery Lager/Ale/ IPA/Fruit Beer/ Creative Craft Beer | |||

Useful capacity | 1000L | |||

Gross capaity | 1400L | |||

Heating way | Electric heating /Steam heating /Direct fire heating | |||

Control System | Fully automated with PLC Siemens /Semi-Automated with PID Schneider | |||

Voltage | Customized | |||

Power | 25kw | |||

Water Consumption | 6T | |||

Floor space | 70-120 ㎡ | |||

Note:1Barrel (BBL) =117 Liter 1Hl=100 Liter 1Gallon=3.7854 Liter 145psi=1MPa | ||||

Opening a brewery? | ||||||

1000L Mash tun | 1 | |||||

1000L Lauter tun | 1 | |||||

1000L Boiling / Whirlpool Tank | 1 | |||||

Heat-exchanger ,pump and etc. | 1 set | |||||

1000L Fermentation tank | Calculate according to yield | |||||

1000L Bright beer tank | 2 | |||||

03 | 2000L Hot water tank | 1 | ||||

Boiler | 1 set | |||||

04 | 2000L Glycol Tank | 1 | ||||

Chiller | 1 set | |||||

05 | 100L Acid Tank | 1 | ||||

100L Lye tank | 1 | |||||

Pump | 1 | |||||

06 | Control system | Semi-automatic/Fully automatic | 1 | |||

1000L/Batch,Up to 4 batches/day, up to 120T /month | ||||||

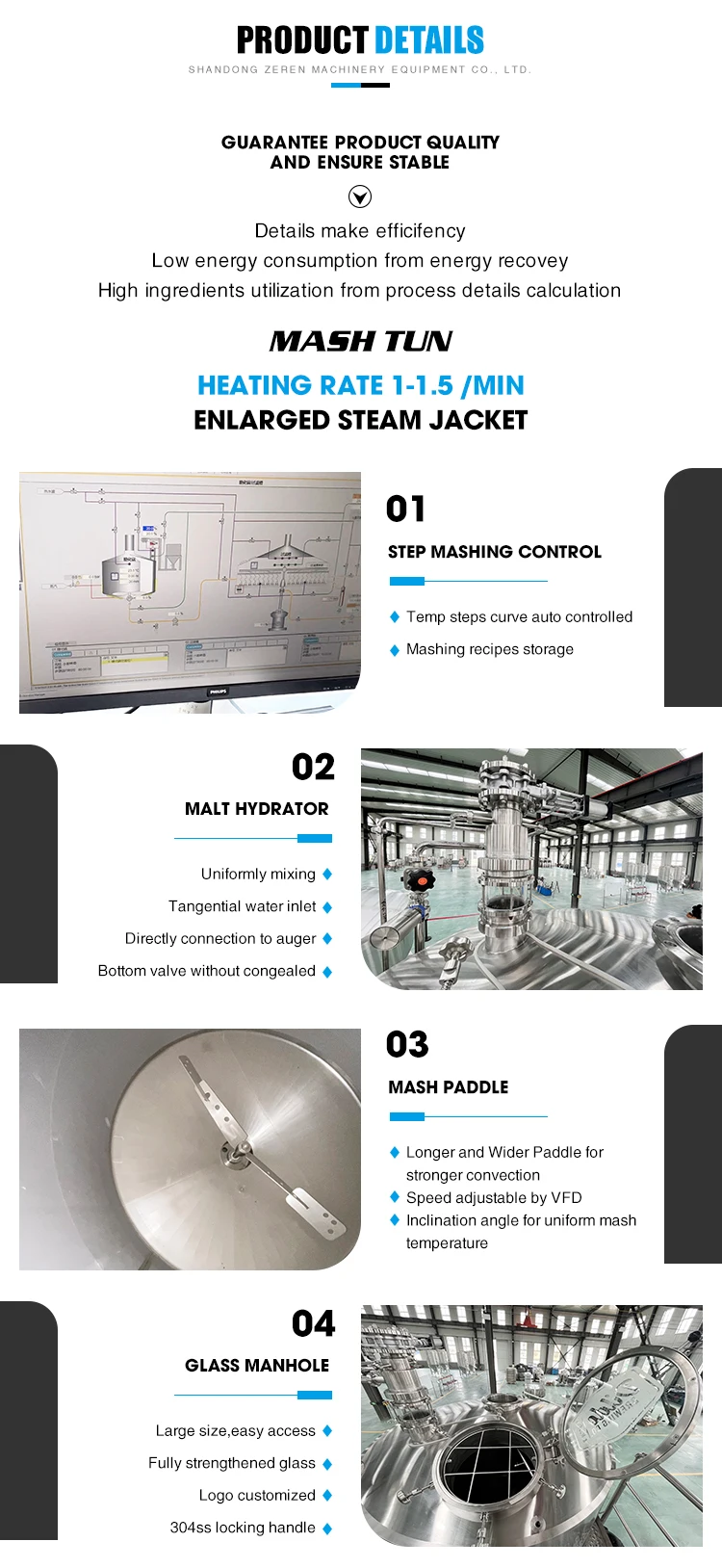

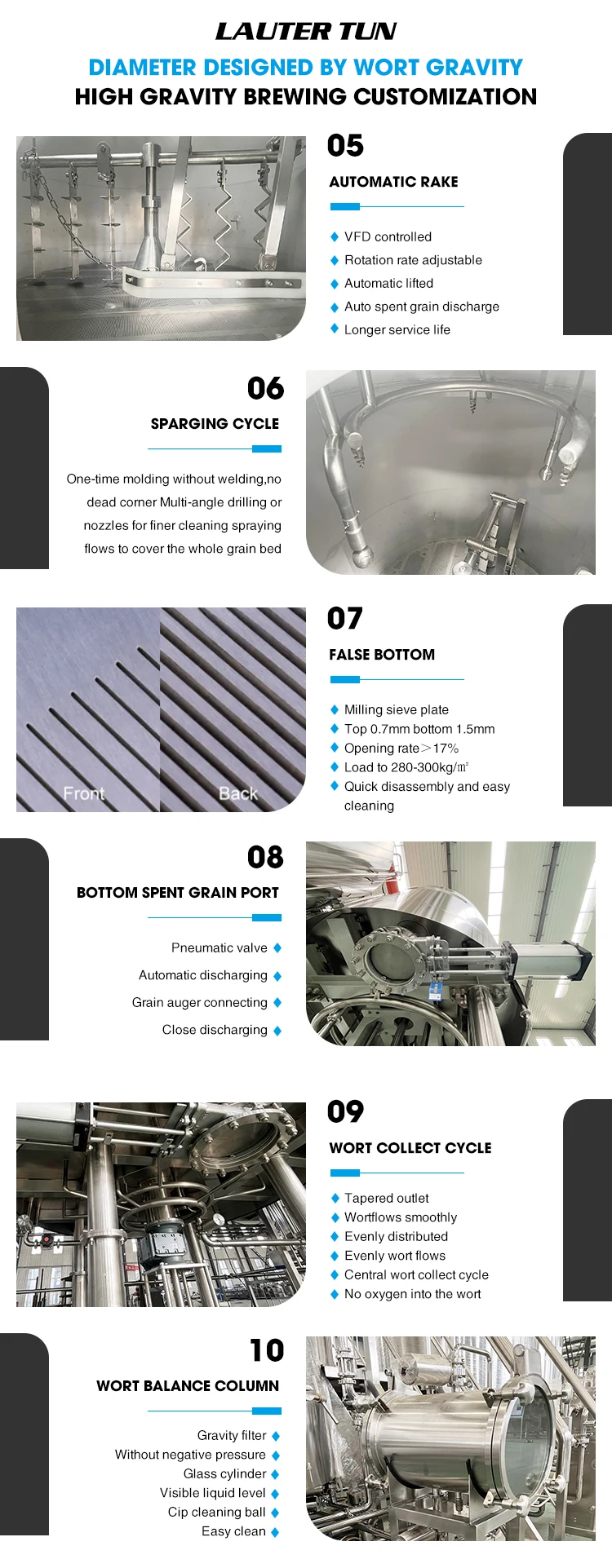

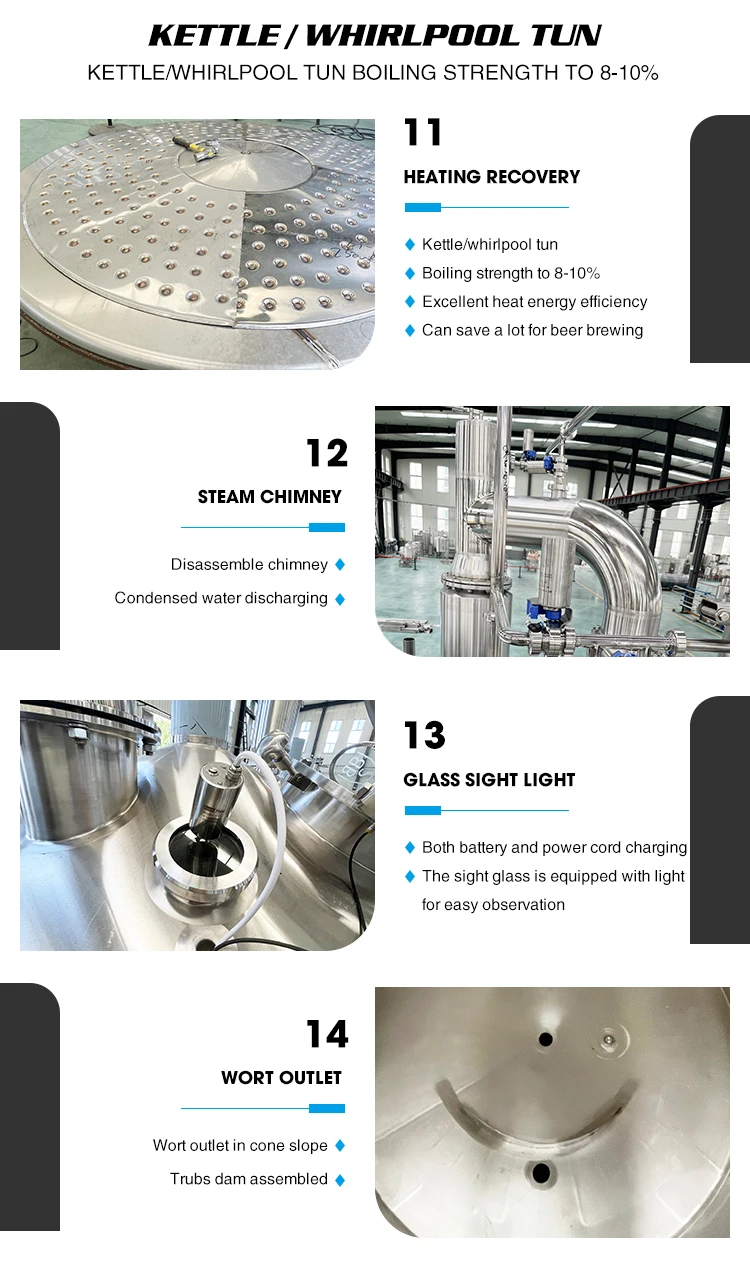

Details Images

Specification selection (L) | Production capacity(L) | Power(KW) | Water consumption(T) | Floor space(㎡) | Roof height(mm) |

ZR-200 | 200L/Batch | Electric heating:24KW Steam / direct fire heating:10KW | 1.2 | 25-40 | 2300 |

ZR-300 | 300L/Batch | Electric heating:36KW Steam / direct fire heating:10KW | 1.8 | 25-50 | 2500 |

ZR-400 | 400L/Batch | Electric heating:48KW Steam / direct fire heating:10KW | 2.4 | 35-50 | 3000 |

ZR-500 | 500L/Batch | Electric heating:55KW Steam / direct fire heating:10KW | 2.9 | 40-60 | 3000 |

ZR-600 | 600L/Batch

| Electric heating:60KW Steam / direct fire heating:15KW | 3.6 | 40-60 | 3200 |

R-700 | 700L/Batch

| Electric heating:65KW Steam / direct fire heating:20KW | 4.2 | 50-70 | 3200 |

ZR-800 | 800L/Batch

| Electric heating:70KW Steam / direct fire heating:20KW | 4.8 | 50-70 | 3200 |

ZR-1000 | 1000L/Batch

| Electric heating:80KW Steam / direct fire heating:25KW | 6 | 70-120 | 3500 |

ZR-1500 |

1500L/Batch

| Steam / direct fire heating:130KW | 9 | 100-200 | 4100 |

ZR-2000 | 2000L/Batch

| Steam / direct fire heating:140KW | 12 | 150-250 | 4400 |

ZR-2500 |

2500L/Batch

| Steam / direct fire heating:150KW | 15 | 180-300 | 4900 |

ZR-3000 | 3000L/Batch

| Steam / direct fire heating:200KW | 18 | 200-350 | 4900 |

ZR-5000 |

5000L/Batch

| Steam / direct fire heating:300KW | 30 | 400 and above | 6000 |

Our Advantages

1.Pre-sale service :

1. Free turnkey beer brewing/filling/packaging solutions.

2. The technical team with 13 years of experience in the beer brewing equipment industry, one-to-one service, provides different brewing process according to your requirements.

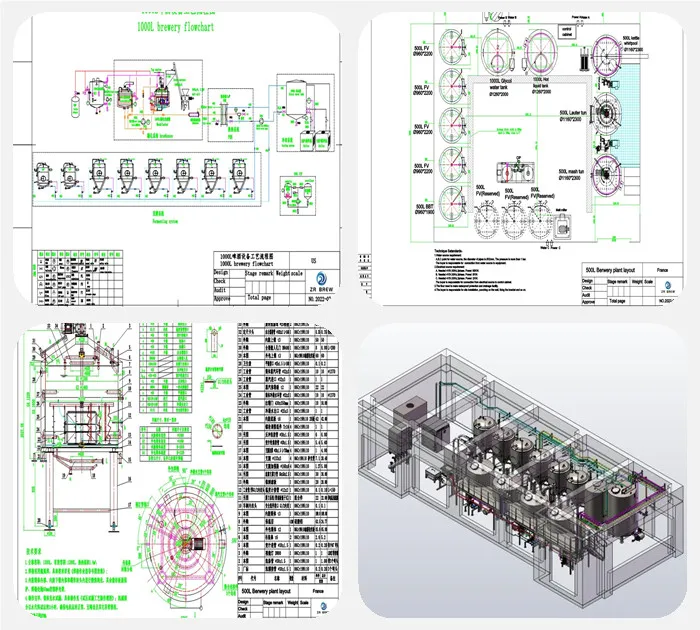

3. According to your site, carry out overall project planning and provide two-dimensional and three-dimensional layout drawings

2.After- sale service:

1. Perfect packaging and transportation, all the tanks are wrapped by three layers of PE protective film, the nozzles are blocked by dust caps, the spare parts are sealed in wooden boxes, the whole loading process is recorded by photos, and accompanied by a checklist, sent to you together.

2. Complete installation and commissioning services, providing detailed installation instructions

in English or French, online video-guided installation and offline door-to-door installation. You can choose between two installation and commissioning modes. We are also establishing technical service teams around the world, so that you can look back worry-free.

in English or French, online video-guided installation and offline door-to-door installation. You can choose between two installation and commissioning modes. We are also establishing technical service teams around the world, so that you can look back worry-free.

3. Lifetime warranty and technical consultation.

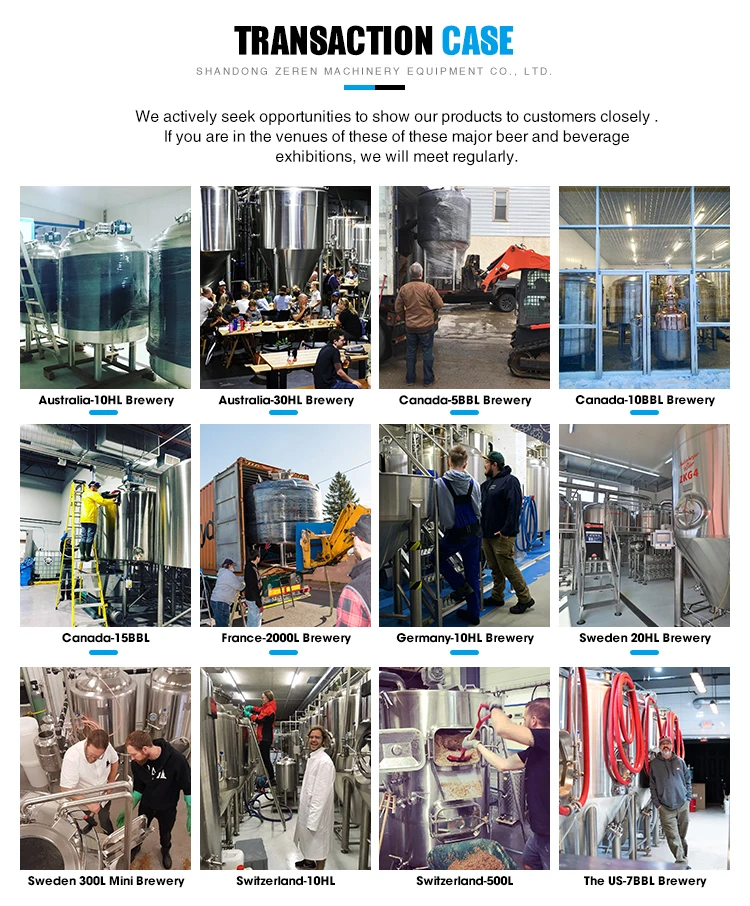

Project Case

Why Choose ZR BREW

ABOUT ZR BREW

Shandong Zeren Machinery Equipment Co., Ltd. referred to as ZR BREW.ZR BREW is an equipment manufacturer focusing on the biological fermentation industry, mainly engaged in beer brewing equipment, providing high-end comprehensive services of product design, production, processing, installation, technical process training. ZR BREW's products have been exported to more than 40 countries and regions in the world. Mainly concentrated in Europe and North and South America.

ZR BREW Company is located in Jinan City, and the factory is located in Dezhou City, covering an area of 10,000 square meters. The company has 52 employees, including 6 senior technicians and 8 intermediate technicians, with more than 20 undergraduates. Project leaders and technical engineers have more than 13 years of work experience in the beer industry.

Certifications

FAQ

1.How to achieve temperature control?

The PLC or digital displayer is connected to the PT100 temperature sensor installed on the tank through the signal line to control the temperature.

2.How to use your machine?

We have paper instructions in English, and we will teach till you do it well.

4.How long is your delivery time?

Usually the lead time for fermenter tank is 30 working days, while the lead time for complete brewery project is 40 working days, timed from final drawing confirmed

5.Do you provide after-sales service?

Yes,we could provide after-sales service.We have many professional engineers, they can go to your place and teach your person installation and brewing.