bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

bitumen storage tanks

Types of Bitumen Storage Tanks

A bitumen storage tank is an equipment utilized for the storage and heating of bitumen usually used for asphalt construction projects. The tanks come in various types with distinct characteristics and functionalities.

-

External heating bitumen storage tanks:

External heating bitumen tanks are designed to keep the material heated. This is vital because of bitumen's low melting point. Often, this type of bitumen storage tank comes with an external heater or a heat exchanger. These parts help maintain or raise the temperature of the bitumen without excessive energy expense. In many cases, external heating is safer and more effective than internal heating, and it minimizes the risk of bitumen degradation due to prolonged heating.

-

Insulated bitumen storage tanks:

Insulation is an important feature of most bitumen storage tanks. Insulated bitumen storage tanks use thermal insulation to keep the stored bitumen at a steady temperature. The insulation reduces heat loss or gain from the external environment. This maintains energy efficiency, minimizes heating or cooling expenditure, and avoids bitumen solidification or tempering.

-

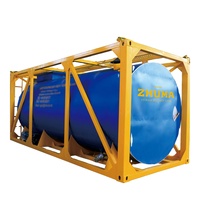

Mobile bitumen storage tanks:

Usually manufactured in the shape of a trailer or container, mobile bitumen storage tanks are easy to transport to different construction sites. These tanks are made with sturdy materials and feature advanced safety methods for secure, safe transportation. Mobile bitumen storage is a practical solution for centralized storage and distribution of bitumen across diverse projects and locations.

-

Vertical bitumen storage tanks:

A vertical bitumen storage tank is the most common shape and style. It has a cylindrical shape and stores big quantities of bitumen. Vertical bitumen storage tanks usually have a heating system, insulation, and a safe bitumen discharge and inlet system.

-

Pressure bitumen storage tanks:

As the name implies, a pressure bitumen storage tank is designed to withstand pressure. These tanks are built with strong steel materials and can store bitumen under high pressure. This increased strength and durability allows for bigger storage capacities and longer product life. Along with that, pressure storage tanks are great for product transportation.

-

Horizontal bitumen storage tanks:

A horizontal bitumen storage tank has a cylindrical shape too, but it is laid down horizontally. It is commonly used in road construction projects. The tank is often divided into a few sections. Each of these sections has an individual heating system for optimal temperature control.

Specifications and maintenance of bitumen storage tanks

Specifications vary depending on the bitumen tank's design and intended purpose. The tank's capacity can range from 10,000 liters to over 100,000 liters. The temperature control system ensures that the bitumen remains at the proper temperature, with heating and insulation components regulating it. Each tank usually comes with a reliable sealing mechanism to guarantee that the content is always safe from any external elements. The material used depends on the bitumen's corrosiveness. Most tanks are made from steel alloys, and the quality of the steel can meet QA requirements. The loading and unloading mechanisms may include pumps, valves, and pipelines, while the safety systems comprise pressure relief valves, emergency shutdown systems, and temperature monitoring. The tank may have insulation to prevent heat loss and protect against burns. Insulation materials may include fiberglass, rock wool, or foam concrete.

Bitumen storage tanks require routine maintenance for optimal functioning and safety. First, operators must conduct inspections regularly to check for signs of wear and damage. Second, they should always follow the manufacturer's guidelines by keeping the tank clean and conducting periodic calibration exercises on the level gauges to ensure accurate readings and third, safe loading and unloading practices should always be used to prevent overfilling or spillage. Fourth, the operators should monitor temperature and pressure regularly to avoid overheating or bitumen solidification. Additionally, they should promptly address any leaks or faults to prevent hazards and ensure the safety systems are in good condition and functioning. More importantly, operators should conduct routine maintenance on the heating systems, including replacing damaged burners or heaters.

Uses of bitumen storage tanks

There are many uses of bitumen storage tanks in the industry, especially when it comes to infrastructure development. The major application of such tanks is to hold and supply high-temperature bitumen. For this reason, bitumen tanks are widely used in roads, construction projects, and other pipeline industries.

In the road industry, bitumen storage tanks are frequently used to supply asphalt for road paving and maintenance. The tanks make sure that the asphalt supply is constant, which supports smooth construction operations. Also, the asphalt supplies are sufficient, which meets the needs of various projects.

In the construction industry, bitumen storage tanks are used to hold various construction materials. The bitumen supplies with additives in the tank can be used for waterproofing, road sealer, and polymer-modified bitumen. Also, the construction industry uses bitumen in adhesive, paint, and insulating materials.

In the oil-refining industry, bitumen storage tanks are used to store and supply bitumen refined from crude oil. It serves as a vital raw material in refineries. Also, these tanks can be used to store the residue from the oil refining process.

In the rubber manufacturing industry, bitumen storage tanks can hold bitumen that is used to produce rubber modified asphalt. The bitumen can enhance the plasticity and elasticity of asphalt, which will improve the performance of the asphalt and increase its durability.

Additionally, some tanks with a large capacity can be used to store bitumen in bulk. The tanks will allow for a more efficient bitumen supply chain and reduce the frequency of bitumen storage.

How to choose bitumen storage tanks

When purchasing bitumen tanks, business buyers should focus on the following factors:

-

Tank materials

Evaluate the materials used in the construction of bitumen tanks, e.g., selecting the tank body materials, such as carbon steel or stainless steel, to meet specific needs.

-

Capacity and size

Consider the bitumen tank's dimensions and capacity to ensure it corresponds with operational requirements. Ensure that there is sufficient storage capacity to meet the demand for bitumen supply.

-

Temperature control system

Choose a bitumen storage tank with an efficient temperature control system that ensures uniform heating throughout the tank. Additionally, select tanks with well-insulated bodies that minimize heat loss and reduce energy consumption.

-

Safety features

Select bitumen storage tanks equipped with safety features, such as pressure relief valves, emergency shutdown systems, and safety signage. Evaluate the compliance of the tanks with local safety regulations and standards.

-

Overall quality

When selecting bitumen tanks, buyers should also focus on the tank's quality and reputation of the manufacturer. Choose a tank with an excellent construction quality and reliable performance. Prefer reputable manufacturers with extensive industry experience who can offer timely technical support and after-sales service.

-

Cost

Evaluate the cost-effectiveness of the tanks. Compare the prices of tanks from different suppliers and evaluate their features and performance. Choose tanks that offer reasonable prices and high performance.

Q&A

Q1: How long can bitumen be stored in a tank?

A1: Bitumen can be stored in a bitumen storage tank for several months or years without losing its properties, provided that the material is kept at the appropriate temperature and that there are no air leaks so that oxidation does not occur.

Q2: What are the key properties of bitumen?

A2: Bitumen is a dense, viscous, and sticky material with waterproofing, elastic, thermal, adhesive, and aging resistance properties.

Q3: What are the three main types of storage tanks?

A3: The three main types of storage tanks are floating roof tanks, fixed roof tanks, and interstitial tanks. It's worth noting that double-skin tanks with an interstitial space between the inner and outer steel walls are also common. Moreover, some are isolated to reduce temperature loss.

Q4: Do storage tanks have vents?

A4: Yes, storage tanks used in asphalt and construction industries usually have vents so that the pressure inside the tank can be equalized with atmospheric pressure. Vents also allow the escape of hazardous vapors to prevent explosions.

Q5: What are the differences between single-wall steel tanks and double-wall tanks?

A5: Single-wall steel tanks have just one steel wall. On the other hand, double-wall tanks have two steel walls, providing additional protection against leaks and spills.