pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

pipe machine

Types of Pipe Machines

There are various types of pipe machines available to help fabricate, weld, or coat pipes. The table below outlines some of these machines.

-

Pipe Bending Machine:

This machine makes pipes bend at any angle without distorting the shape. It does this by using a form that has the same shape as the internal cavity of the pipe. There are several types of pipe bending machines, like hydraulic, manual, or CNC bending machines.

-

Pipe Cutting Machine:

This machine is made to cut straight pipes or slices from round pipes. Pipe cutting machines can make accurate and efficient cuts with minimal waste. The machines can cut metallic or non-metallic pipes and are usually made of very tough steel. They come in several types, including laser cutting machines, CNC cutting machines, gas cutting machines, and pipe notching machines.

-

Pipe Welding Machine:

This machine joins pipes together by melting filler metal into the gap between the pipes. Pipe welding machines are made to ensure strength, uniformity, and smooth flow, especially in pipes used for gas or fluid transfer. There are several types of pipe welding machines, including argon arc welding machines and TIG welding machines.

-

Pipe Threading Machine:

This machine creates tapered helical grooves (or threads) on the outer surface of cylindrical pipes. Threaded joints provide mechanical strength and resistance to leakage. The pipe threading machine can be manual or automatic and is commonly made of cast iron.

-

Rollforming machine:

A roll-forming machine makes pipes by sequentially passing flat metal parts through rotating rolls. The rolls change the flat metal parts into a circular shape and produce the desired profile. This machine works well for high-volume production of cylindrical pipes with small diameters.

-

Laser Cutting Machines:

This machine cuts complex shapes and profiles onto metal pipes with the aid of laser beams. Laser cutting machines provide accurate, high-speed cutting without the need to make any tooling, so the time taken to set it up is reduced. This machine is used for custom pipe fabrication.

-

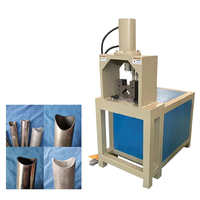

Pipe Notching Machine:

This machine creates notches (or grooves) on pipes to enable precise fit-up and joints, especially for structural assemblies or tubing. The machine can be automatic or manual, and it is commonly used in the construction industry.

-

Pipe Coating Machines:

This machine applies protective coatings to pipes to help prevent corrosion, abrasion, or other environmental damage. Coating machines improve durability and longevity, and they are also used in the oil and gas industry.

-

Hydraulic Pipe Crimping Machine:

This machine changes the shape of a pipe by using high-pressure fluid power to form a die. It is used to make pipes with connectors in hydraulic systems and automotive applications.

Specifications and maintenance of pipe machines

Specifications

-

PVC pipe machine:

PVC pipe-making machines are made for manufacturing pipes from polyvinyl chloride (PVC), which is a plastic commonly used for water supply, drainage, and other applications. The specifications can vary depending on the model and manufacturer.

-

Pipe threading machine:

The pipe-threading machine specification involves the threading capacity, power, and speed.

The threading capacity means the diameter and length of the pipe that can be threaded. The power refers to the motor power of the machine, which is usually expressed in horsepower (HP) or kilowatts (KW). The speed is measured in revolutions per minute (RPM).

For example, a conventional pipe-threading machine can thread pipes with a diameter of up to 2 inches and a length of up to 10 feet. Its motor power is about 3 HP, and the threading speed is about 40 RPM.

-

Hydraulic pipe bending machine:

Hydraulic pipe bending machines are used to bend various types of pipes with hydraulic pressure. The specifications of the machines include the bending capacity, bending radius, control system, and dimension.

The specification may vary depending on the model and the manufacturer. Taking one example, the machine can have a bending capacity for bending pipes with a diameter of 1 to 6 inches. Its bending radius could be 2 to 6 feet. Furthermore, it might have a digital control system or a manual gearbox, and its dimension could be 4x5x3 meters.

Maintenance

- Pipe extrusion machine:

In order to keep the machine operational and get ready for use, it is essential to check and perform maintenance on the extrusion head on a regular basis so as to make sure that the die and the screen pack are not blocked or contaminated. Clean them up occasionally while doing so. The machine should be calibrated from time to time to make sure that the diameter of the pipe and the pressure are exactly the same. Perform lubrication on the moving parts of the machine now and then so as to reduce wear and tear and extend its service life.

- Threading machine for pipe:

Lubricate the machine components like gears, bearings, and threading tools regularly to keep the machine operational smoothly. Check the machine's electrical systems and cable connections from time to time to ensure there are no loose or damaged connections. The hydraulic oil and filters in hydraulic machines should be checked and replaced so that the hydraulic system can work stably.

- Automatic pipe bending machine:

More importantly, the hydraulic system and electrical components of the automatic machines should also be checked to ensure the hydraulic system and electrical system continue to work properly and be energy-efficient.

Applications of Pipe Machines

Due to their adaptability, pipe machines are used in various sectors and applications.

-

Plumbing and Construction

In the construction sector, specialized pipeline systems produced using pipe machines are employed for structural support, insulation, cooling systems, and other elemental constructions. Insulated pipes, for instance, are designed to keep liquids hot or cold to prevent energy waste. Conversely, CPVC is valued for its capacity to endure extreme temperatures. Such characteristics make these materials suitable for specialized construction requirements. Furthermore, custom pipe fittings enable the customization of plumbing systems to ensure a perfect fit in distinctive architectural designs.

-

Automotive Industry

In the automotive sector, exhaust pipe machines help manufacture exhaust systems and other automotive components from various metals. These machines are highly precise and can bend and shape pipes at different angles and radii for complex exhaust system assemblies. The durability and corrosion resistance of the machinery are crucial for ensuring that the vehicle can withstand environmental exposure over its lifetime.

-

Oil and Gas Industry

The oil and gas industry makes extensive use of pipe machines. They build large-diameter, heavy-wall pipes essential for transporting oil and gas from extraction sites to refineries and distribution networks. The pipes must be strong enough to withstand high-pressure and -temperature conditions. Furthermore, machines that weld the pipes guarantee a solid and reliable transmission, while the pipe coating equipment protects them from corrosion and environmental damage.

-

Aerospace and Automotive Industries

The aerospace and automotive industries rely on precision pipe machines to manufacture lightweight tubes and pipes. They use these components in structural assemblies, exhaust systems, and high-performance vehicles. Aerospace-grade materials like titanium and lightweight alloys guarantee the reliability and safety of aircraft. Similarly, the automotive industry demands lightweight materials that improve vehicle performance and fuel economy.

-

Home and Garden

Pipe machines are also used in the home and garden sector, where they manufacture decorative pipes like smoking or drinking straws. The cosmetic pipes are made of either glass or acrylic and may have beautiful designs. On the other hand, stainless steel and PVC are well-known durable materials used to manufacture garden hoses. Durable pipe machines guarantee that these products can survive the elements and provide reliable service.

How to Choose Pipe Machines

Buying a pipe machine for sale is not an easy task. The following key considerations can help buyers choose the right pipe-making machines for their specific requirements.

-

Production Needs

-

Material Compatibility

-

Machine Types and Technologies

-

Operational Complexity

-

Budget Constraints

First, buyers should determine what their production demands are. Hence, they should consider factors like the required pipe dimensions, materials, shapes, and quantities. Also, they need to evaluate their pipeline application needs. For this reason, industrial buyers need to ask themselves, what are the pipeline uses? Do they need strength, flexibility, and other specific features? When they understand their production requirement better, they can choose a machine with sufficient capacity.

Industrial buyers must consider the materials they'll be using. They must choose machines that can handle the specific materials they want to use, whether they're stainless steel, carbon steel, galvanized steel, aluminum, or plastic. The machine's design and technology must be compatible with the materials in question to ensure smooth operation and quality output.

The type of machine chosen depends on the material being used to create the pipe. For example, conventional welding machines like high-frequency welding machines, low-frequency welding machines, and contact resistance welding machines play a significant role in pipes made with specific metals. On the other hand, laser welding machines are commonly used for welding stainless steel pipes. For plastic pipes, extrusion machines are preferred. Buyers must familiarize themselves with the various types and technologies of pipe-making machines available so they can consider their advantages, limitations, and suitability for their applications.

Some pipe machines have easy-to-use controls and instructions, while others require more expertise and training. More complex machines may have digital controls, automated parts, and a higher level of automation. In this case, an operator needs skills and training to work properly. If an operator's skill set is limited, it is best to settle for a machine that the operators will easily use. Choose the machine with basic operation and manual control.

Pipe machine FAQ

Q1: What types of materials does a metal pipe manufacturing machine work with?

A1: Generally, this machine is made to make pipes using various metal materials. Machines that manufacture pipes for non-metal materials, however, could be made for materials like plastics, compounds, or rubbers.

Q2: Can a single pipe manufacturing machine handle different pipe sizes?

A2: No, generally, it is not possible. There are different machines to handle the production of different pipe sizes. However, some machines may have interchangeable parts that allow them to produce pipes of various sizes.

Q3: Is operator training necessary for effective pipe machine operation?

A3: Yes, operator training is necessary. The training ensures the operators understand the manufacturer's instructions and know how to set up, operate, and maintain the machine safely and efficiently.