turbine flowmeter

turbine flowmeter

turbine flowmeter

Industrial Production DN100 Digital Smart Card Type Ultrasonic Flow Meter With RS485 Modbus Protocol

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

Plus Discount Digital Diesel Alcohol Methanol Beverage Quantitative Control Liquid Turbine Flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

turbine flowmeter

Types of Turbine Flowmeter

Turbine flowmeter manufacturers produce several types of turbine flowmeters today. These include the following:

-

Inline Turbine Flowmeters

Inline turbine flow meters are mostly integrated into pipes carrying fluids. These meters are designed to provide accurate readings for industrial applications. They ensure minimal impact on the overall fluid movement. They are mostly preferred in settings that deal with large volume flow. Such settings include oil and gas, water treatment, and any chemical processing.

-

Expendable Turbine Flowmeters

Expendable turbine flowmeters are mainly used in temporary settings. These include environments like construction zones or mining sites where the flow of aggressive materials is common. These meters feature a durable build and a blade design that can withstand harsh conditions. They also provide accurate measurements of abrasive or corrosive fluids. As such, they are ideal for short-term monitoring purposes.

-

Battery-Powered Turbine Flowmeters

These flowmeters are specifically built for remote areas where power supply may not be available. They come equipped with efficient long-lasting batteries. These facilitate energy-saving operations without compromising on the accuracy of the readings. Their main strength is portability, which makes them ideal in agricultural, mining, or field service applications.

-

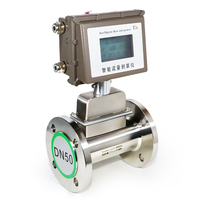

Digital Turbine Flowmeters

Digital turbine flowmeters are aimed at providing real-time data processing and display. This allows immediate flow rate and totalized volume readings. Their electronic components ensure high accuracy, especially when compared to analog models. Moreover, many digital meters come equipped with communication protocols. This makes them suitable for integration into advanced monitoring systems. The systems often feature in industrial sectors like manufacturing, oil and gas, and chemical processing.

-

Mechanical Turbine Flowmeters

These traditional mechanical turbine flowmeters include analog displays and simple designs. These mechanical meters provide basic measurements with lower costs. They are still relevant in applications with less stringent accuracy requirements. For example, they can work in smaller industries or service sectors that require routine monitoring of fluid flow.

Materials And Design For Turbine Flowmeters

Turbine flowmeter suppliers stock models designed using specific materials for each component. These materials largely influence the flowmeter's performance, accuracy, and application suitability. The materials also affect how well the turbine flowmeters can withstand different types of fluid and environment. Below are such materials:

-

Turbine Blades

The turbine blades on a turbine flowmeter are usually constructed from high-strength materials. Such materials are often resistant to wear and tear experienced from constant movement. As such, stainless steel and titanium offer durability and resistance to corrosion. This makes them ideal for harsh chemical environments. Some industrial flow meters come with carbide-coated blades. These greatly increase the meter's longevity. This is especially so when dealing with abrasive fluids like those commonly found in mining or chemical processing.

-

Housing

The flowmeter's exterior housing is mainly designed using materials that ensure protection. Such materials also ensure that the electronics are safeguarded from the harsh operating environment. Common materials for the housing include aluminum, brass, and stainless steel. All these materials offer different levels of protection against moisture, dust, and corrosive substances. Stainless steel is often chosen for its robustness and resistance to a wide range of environmental factors. This makes it suitable for both outdoor and industrial indoor applications.

-

Strainer

The strainers are built from stainless steel or similar durable alloys. They have to be as equally durable as the Flowmeter parts. After all, they need to ensure contaminants are filtered out efficiently. Stainless steel offers strength and corrosion resistance. It also ensures that the strainer can handle not only aggressive fluids but also adverse operational conditions. This makes it rugged and reliable for extended service life.

-

Sensors

The sensors in turbine flowmeters are typically crafted from high-quality metals like platinum or stainless steel. These materials are chosen for their exceptional conductivity and corrosion resistance. These factors allow the meters to function accurately in both harsh chemical and high-pressure environments. Although stainless steel is often the material of choice for chemical-heavy industries, platinum sensors are ideal for high-precision applications in aerospace or pharmaceuticals.

How To Choose Turbine Flowmeters

Business owners should consider prioritizing the following options when choosing turbine flowmeters for sale:

-

Blood and Irrigation Meters

In medical applications, accuracy is vital. Thus, turbine flowmeters designed for blood and irrigation fluids are mostly equipped with sensitive turbines. These are capable of measuring low flow rates with pinpoint accuracy. Their high level of sanitization also makes them ideal for this space.

-

Petroleum and Fuel Meters

Industrial turbines work great when measuring fuel flow for trucks, ships, and jets. They come equipped with tough blades and a durable exterior to withstand the viscous nature of these liquids. Their expansive ability to measure various flow rates ensures consistent accuracy regardless of the movement speed.

-

Pharmaceutical and Chemical Meters

For the pharmaceutical and chemical industries, turbine flowmeters are usually constructed from materials resistant to corrosion. This allows them to work seamlessly with both corrosive and non-corrisive fluids. The meters also feature explosion-proof designs and sensors that can easily withstand high pressures and temperatures.

-

Water and Waste Water Meters

In water treatment and waste management, turbine flowmeters are mainly utilized for their efficiency with large-volume flows. They are generally equipped with electronic sensors to minimize mechanical wear. This increases efficiency and reduces maintenance costs. Their ability to totalize flow also helps in regulatory compliance monitoring.

-

HVAC and Cooling System Meters

In heating, ventilation, and air conditioning (HVAC) systems, turbine flowmeters measure chilled water and other heat transfer fluids. They provide precise flow measurements. These help to optimize energy usage. Their compact design also allows easy installation in tight spaces. This makes it easier to integrate into existing systems.

Uses Of Turbine Flowmeters

Industrial, medical, agricultural, and automotive turbine flowmeters use different flowmeters. Below are some such uses:

-

Monitoring Fuel Injection in Engines

Turbine flowmeters can help measure the precise amount of fuel injected into an engine. They help ensure optimal performance and efficiency. By providing real-time measurements, these flowmeters help automotive control systems adjust fuel-air mixtures accordingly during variations in engine operation. This results in improved emissions and better fuel economy.

-

Precision Agriculture

Turbine flowmeters enable accurate measurements of irrigation water and fertilizer in agricultural systems. They ensure crops receive the right amount of resources for healthy growth. This not only increases crop yields but also conserves water and reduces wastage of vital resources. Farmers with turbine flowmeters installed have reported operating with increased efficiency and contributing to sustainable farming practices.

-

Medical Applications

Turbine flowmeters also measure blood and other fluids in medical machinery. Their accuracy, coupled with non-intrusive measurements, makes them indispensable for calculating medication doses and monitoring fluids to ensure patient safety. They are critical components in ventilators, infusion pumps, and other medical equipment. They help healthcare providers offer timely treatments and reduce medical errors.

-

Water Treatment and Distribution

In water treatment plants, turbine flowmeters help measure the volume of water treated and distributed. They help utilities manage supply effectively, ensuring communities receive clean water. Their precision helps in regulatory compliance and detecting leaks or inefficiencies in distribution systems. This ultimately leads to better management of vital resources and improved public health.

-

Offshore and Onshore Oil and Gas Industries

Turbine flowmeters can help measure the amount of oil and gas both industries extract, transported, and processed. They provide accurate measurements required for production calculations and regulatory compliance. They also handle the high pressures and harsh conditions commonly found in these environments. This makes them reliable for crucial measurements while minimizing maintenance needs.

Q&A

Q1. How can buyers increase the accuracy of turbine flowmeters?

They can increase the precision of turbine flowmeters by closely examining the materials used to create them. Materials like stainless steel and titanium are known for their resistant properties. Hence, they will also provide a high level of accuracy as the materials will not corrode. Business owners should also ensure they offer turbine flowmeters with strainers to filter contaminants. Finally, they should consider stocking digital turbine flowmeters. They not only provide accurate real-time data but also allow immediate flow rate and totalized volume readings.

Q2. Which factors should businesses consider the automotive reference to when acquiring turbine flowmeters?

Automotive sector officials should consider the strength, resistance to corrosive materials, and accuracy of the flowmeters. They should also ensure they are equipped with sensitive turbines. This allows the flowmeters to measure low fuel injection rates with great precision. Other than accuracy, fuel flow turbines should easily integrate with existing systems. More importantly, they should be durable to withstand harsh engine conditions.

Q3. Which metrics can communicate how well turbine flowmeters perform in terms of resource management?

Turbine flowmeters in water treatment plants can measure the amount of water treated and divided, thus directly calculating wastage. Management systems in agriculture can measure irrigation and fertilizer amounts, ensuring only what is needed is utilized. In oil and gas industries, turbine flowmeters can measure the amount extracted, transported, and processed. This will directly reduce wastage.

Q4. Which recent trends in turbine flowmeters can potential customers benefit from?

The rise of IoT has brought untamed remote turbine flowmeters, which are easily monitored and controlled from anywhere. There are now smart turbine flowmeters that integrate with other industrial systems. This allows effortless data sharing. There are also digital flowmeters that outperform mechanical flowmeters in accuracy and efficiency. Finally, thanks to the strong advancements in materials, flowmeters with better resistance to high-pressure environments are now readily available.