ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

ultrasonic level meter

Introduction to Ultrasonic Level Meter

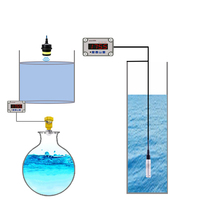

The ultrasonic level meter is an innovative instrument utilized primarily for measurement in various industrial applications. These meters employ ultrasonic sound waves to determine the distance to a liquid or solid surface, providing reliable and efficient level measurement. With their non-contact operating principle, ultrasonic level meters are ideal for a variety of environments, meeting the varied demands of industries such as water treatment, food and beverage, petrochemical, and more.

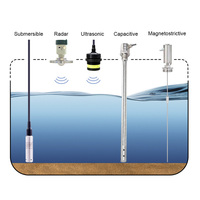

Types of Ultrasonic Level Meters

Ultrasonic level meters come in several types, each designed to cater to specific needs and conditions:

- Contact Type Ultrasonic Level Meter: These meters use direct contact with the material being measured. They are suitable for thicker materials and harsh conditions.

- Non-Contact Type Ultrasonic Level Meter: This type emits ultrasonic waves from a distance, making it perfect for hazardous environments where direct contact is unsafe.

- FM Certified Ultrasonic Level Meter: Specifically designed for use in flammable environments, ensuring safety and regulatory compliance.

- Guided Wave Ultrasonic Level Meter: Utilizes a probe that transmits ultrasonic waves along a cable. It is excellent for measuring liquids in small or inaccessible tanks.

Function, Feature, and Design of Ultrasonic Level Meters

Understanding the function and features of ultrasonic level meters is paramount in selecting the right device for your applications. Key functionalities include:

- Non-Contact Measurement: Utilizing sound waves eliminates the need for intrusive devices, making measurements more accurate and reducing potential contamination.

- High Accuracy and Reliability: Ultrasonic level meters boast high precision in measurements, ensuring that you get reliable data for monitoring and controlling processes.

- Versatile Applications: These meters can measure various materials, including liquids, slurries, and solids, making them a flexible choice for diverse industries.

- Robust Design: Built to withstand harsh industrial environments, many ultrasonic level meters feature rugged housings and are resistant to dust and moisture.

Applications of Ultrasonic Level Meters

The versatility of ultrasonic level meters is evident in their wide range of applications across different industries:

- Water and Wastewater Management: Essential for monitoring levels in tanks and ensuring efficient operations in treatment plants.

- Petrochemical Industry: Used to measure levels of fuels and chemicals, where safety and accuracy are critical.

- Food & Beverage Processing: Applicable in controlling ingredient levels in production processes while complying with hygiene standards.

- Mining and Aggregate Industries: Helps in tracking material levels in bins and stockpiles, ensuring efficient resource management.

Advantages of Using Ultrasonic Level Meters

Utilizing ultrasonic level meters provides numerous advantages that contribute to both efficiency and safety in operations:

- Minimal Maintenance: With no moving parts, ultrasonic meters require less upkeep compared to mechanical alternatives.

- Cost-Effective: Their long lifespan and reliable operation minimize replacement costs, making them a cost-effective solution.

- Quick Response Time: Ultrasonic level meters offer real-time data, crucial for quick decision-making processes.

- Environmentally Friendly: As non-contact devices, they reduce the risk of contamination, thereby promoting sustainable practices.