vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

vacuum seeder

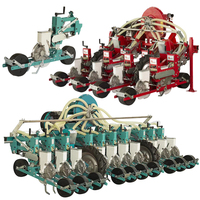

Types of vacuum seeders

A vacuum seeder comes in various types and models, which are typically made of plastic, stainless steel, or aluminum. The stainless steel seed plates are ideal for heavy-use applications because they are resistant to wear and damage, particularly when dealing with large-scale food production. Aluminum plates, on the other hand, are preferable for light-duty modeling. Like the stainless steel plates, they have a durable design, but they also have a lightweight build that is easy to handle. Vacuum seed trays and plates can be found in one of these three materials. They come in different styles, including root cubes, open flats, and flexible fabric trays.

Although all kinds of vacuum seeders are built to uniformly plant seeds of various shapes and sizes, specific innovations and designs have resulted in differing efficiencies. Here are some of the most common kinds of vacuum seeders:

- Multiple-row vacuum planter: This device utilizes a disc with varying-sized holes to create suction for seed placement, and it is capable of efficiently planting seeds in clusters.

- Plate seeders: Vacuum plate seeders utilize a flat plate on which seeds are distributed evenly with suction cups. They are ideal for planting crops requiring precise spacing, such as lettuce and flowers.

- Vacuum finger seeder: This rotary seeder features a vacuum plate equipped with fingers that gently picks up seeds using suction. It is suitable for planting small to medium-sized seeds, such as grass and wildflower mixes.

When choosing a vacuum seeder, buyers should consider its construction, adjustability, compatibility with seeds, and ease of use and cleaning. They should also decide between a manual or a given model basing it on the farm’s size and planting needs. The type of seed, the desired planting depth and spacing, and the terrain of the seeded area all influence the selection process. Some seeders are designed for precision planting in rows, while others are meant for broadcasting over a large area.

Specification and Maintenance

A vacuum seeder machine has many specifications, and the right choice depends on the scale of farming or the seeding requirements. Some key specifications include the seed plate, vacuum pump, seed hopper, adjustable settings, compatible seeds, and overall dimensions.

- Vacuum Plate: Vacuum seeders normally come with interchangeable seed plates. These plates vary in size, shape, and hole configuration to match the type and size of seeds being planted. For instance, large round seeds may require a larger plate with fewer holes, while small, tiny seeds will need a plate with more holes.

- Vacuum Pump: The job of the vacuum pump is to generate the suction force that picks up seeds from the hopper. The power and efficiency of the pump will affect how well it works, mostly under different speeds and settings.

- Seed Hopper: Vacuum seeders have different hopper sizes. The size will determine how many seeds can be stored and planted during one seeding run. The adjustable or fixed dividers within the hopper also affect the type of seeds that can be used.

- Adjustable Settings: Vacuum seeders have different types of adjustable settings for seed depth and spacing. The row width also varies according to the type of vacuum seeder. Whether it is a plate or a drum model, these adjustments allow operators to have control and precision over seeding.

- Compatible Seeds: Not all vacuum seeders work with every seed type. Dust-like seeds, for example, must have sufficient density to work well in the vacuum seeder. Operators Must consider the kind of seed before choosing a vacuum seeder.

- Dimensions: The dimensions of the vacuum seeder itself will determine how much space it takes up and whether it can be easily transported. The weight of the machine will also affect how it is lifted and used on different kinds of farms.

Using a vacuum seed drill properly and cleaning it are the two most important things to do to keep the device working over a long time. Carefully read the operator manual to set the seeder correctly for the desired crop. Before starting planting, make sure the vacuum level and plate configuration are adjusted as per the crop requirements. While using the vacuum seed plate seeder, regularly inspect the vacuum plates for blockage and clean them as required.

After seeding, the operator should remove debris and seeds from the hopper and vacuum plates. Check all the moving parts of the seeder and apply lubricant to ensure smooth functioning.

Application scenarios of vacuum seeders

-

Large-scale planting farms:

In large-scale planting farms such as vegetable greenhouses, orchards, and fields, a vacuum seed planter can ensure accurate and efficient planting. It meets the needs of large-area planting.

-

Agricultural production:

In high-efficiency and standardized agriculture, using a vacuum seeder can improve the quality of seeding, increase the rate of emergence, and enhance the reliability of agricultural production. It is applicable to different types of soil and environmental conditions.

-

Specialized planting:

In specialized planting, such as planting economic crops and ornamental plants, using vacuum seeders for planting can meet the requirements of precise seeding and is suitable for different kinds of seeds.

-

Land preparation and planting integration:

In the integrated operation of land preparation and planting, a vacuum seeder can be used to achieve simultaneous soil preparation and seeding, thereby improving operational efficiency and reducing labor intensity.

-

Forestry planting:

In forestry planting, a vacuum seeder for trees can be used to achieve accurate planting of tree seeds, promote afforestation efficiency, and ensure the stability of forest stands.

-

Customization service:

It can be customized according to specific needs and applications, such as changing the vacuum box, seed plate, and other accessories to adapt to different kinds of seeds and planting conditions.

How to Choose a Vacuum Seeder

-

Understand Requirements:

Determine the specific needs for seed planting. Consider the types of seeds, quantity, soil conditions, and the crops that will be planted. Also, take into account the size of the operation, budget, and desired planting accuracy and efficiency.

-

Types of Vacuum Seeders:

Familiarize with different types of vacuum seeders, such as stationary, mounted, or pull-behind models, as well as their sizes. Choose the most suitable based on the previously determined requirements.

-

Field Capacity:

When choosing the right vacuum seeder machine, it is important to consider its field capacity. Field capacity refers to the maximum amount of work that can be done in a specific field within a given period. Factors such as soil conditions, terrain, and the type of seeder being used can all impact the field capacity. By selecting a vacuum seeder with an optimal field capacity for the current conditions, one can ensure efficient planting and minimize downtime.

-

Row Spacing and Depth Control:

The row spacing and depth control of a vacuum seeder determines how accurately seed can be placed in the field. This impacts both crop yields and harvesting efficiency.

It is essential to choose a vacuum seeder that provides sufficient flexibility in row spacing to match the desired configuration for the crops being planted. Moreover, depth control should also be considered when selecting a vacuum seeder. The seeds must be sown at the appropriate depth to promote uniform emergence and proper development. Different soil layers may require varying depths for successful planting, making it important that depth can be accurately controlled with the selected seeder machine. -

Check Precision and Reliability:

Assess the accuracy and dependability of various models. Precision refers to how well the seeds are measured and distributed, ensuring that they are placed uniformly with the correct quantity. It is crucial for maximizing crop yield potential but must also be consistent over time to build trust in its performance.

When researching vacuum seeders, find out if there is any feedback from farmers who have used them before. Look at their cropping system and see if they encountered issues with inconsistent seeding rates or failures during operation. This information can help identify trustworthy machines that deliver precision sowing consistently.

-

Operating Ease and Maintenance:

Consider how user-friendly the seeder is and what kind of maintenance it will need. Look for a vacuum seeder that has an intuitive design, making it easy for operators to plant with accuracy and efficiency. Also, find out if the machine requires complex upkeep or if routine checks and simple repairs suffice to keep it running well over time.

-

Cost and Quality Balance:

Evaluate the price of different models in relation to their features and performance. Find a good balance between cost and quality by comparing what each model offers within the budget.

Vacuum seeder Q&A

Q1: Are all vacuum seeders the same size and adjustable for all types of crops?

A1: No, not all vacuum seeders are the same size. They are made in different sizes to accommodate various crops. The plate or cup size can be adjusted to suit different types of seeds.

Q2: Are vacuum seeders easy to use?

A2: Yes, vacuum seeders are user-friendly and can be used by farmers of all sizes from large commercial to small-scale farming.

Q3: What are the advantages of using a vacuum seeder?

A3: Vacuum seeders are an efficient way to plant large areas. They offer precision planting which reduces the need for thinning. They are versatile and can be adjusted for various seeds and plate configurations. They save time and labor costs compared to hand-seeding methods.

Q4: What are the disadvantages of a vacuum seeder?

A4: The disadvantage of vacuum seeders is that they can be costly and may not be economically feasible for small-scale farmers. They can also require additional equipment to be used with different types of seeds.