vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

vinyl slitter

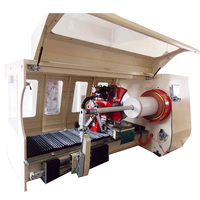

Introduction to Vinyl Slitter

A vinyl slitter is a specialized machine used in the manufacturing and processing of vinyl materials. It is designed to cut large vinyl rolls into smaller, more manageable sizes with precision and efficiency. Vinyl slitters are essential equipment for industries such as signage, advertising, packaging, and textiles where vinyl materials are widely used.

Technical Specifications and Features

The vinyl slitter typically features a sturdy frame to support the weight of heavy vinyl rolls, sharp blades for precise cutting, and adjustable settings for width and length customization. These machines are equipped with advanced control systems for accuracy and consistency in cutting. The power capability of a vinyl slitter can range from 20 to 50 hp, depending on the model and capacity. Additionally, some models come with safety features such as emergency stop buttons and protective guards to ensure operator safety.

Types of Vinyl Slitters

There are different types of vinyl slitters available in the market to cater to varying production needs. Basic vinyl slitters are manual or semi-automatic, requiring operator intervention for loading and unloading vinyl rolls. On the other hand, advanced models are fully automatic with computerized controls that can handle high-volume production efficiently. Some vinyl slitters are specifically designed for cutting specialized vinyl materials like reflective vinyl or heat transfer vinyl.

Advantages of Using a Vinyl Slitter

The use of a vinyl slitter offers several advantages to businesses in the vinyl processing industry. By accurately cutting vinyl rolls to the desired sizes, these machines help in reducing material waste and optimizing production efficiency. The precision cutting capabilities of vinyl slitters ensure consistent quality in the final products, leading to customer satisfaction and increased profitability. Moreover, automation features in modern vinyl slitters save labor costs and improve overall productivity.

Choosing the Right Vinyl Slitter

When selecting a vinyl slitter for your business, consider factors such as the volume of vinyl processing, the types of materials being cut, required cutting precision, and available space for installation. Choose a machine with the appropriate cutting width and blade configuration to meet your specific production requirements. It is also important to ensure that the vinyl slitter is easy to operate, maintain, and has reliable after-sales support from the manufacturer.

Maintenance and Care Tips

Proper maintenance of a vinyl slitter is crucial to ensure its longevity and optimal performance. Regularly inspect the blades for sharpness and any signs of wear, and replace them as needed to maintain cutting quality. Keep the machine clean from dust and debris that can affect its operation. Lubricate moving parts according to the manufacturer's recommendations to prevent friction and ensure smooth operation. Following a routine maintenance schedule will help avoid unexpected downtime and costly repairs.