Small Scale Gold Extraction Recovery Washing Machine/Manganese Ore Wash Mining Equipment/Gold Processing Plant for Sale

US $6,599.00 / set

1 set(s)Minimum order

Type:

Flotation Separator

Production Capacity:

10-500t/h

Place of Origin:

Henan, China

Brand Name:

ZOOMJO

Voltage:

220/380/440V

Dimension(L*W*H):

Customizable

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Flotation Separator |

|---|---|

| Production Capacity | 10-500t/h |

| Place of Origin | Henan, China |

| Brand Name | ZOOMJO |

| Voltage | 220/380/440V |

| Dimension(L*W*H) | Customizable |

| Weight | 10000 KG |

| Warranty | 2 years |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | PLC, Engine, Bearing, Gearbox, motor |

| Key Selling Points | Easy to Operate |

| Product Name | Gold Extraction Recovery Washing Machine |

| Color | Customers' Requirements |

| Application | Gold Processing Plant |

| After Sale Service | Engineer Overseas Service |

| Price | Competetive (Can Negotiate) |

| Factory | 50,000 Square Meters Closed Workshops |

| Installation and Trial | We Can Send Engineer for Guidance |

| Capacity | 10-500t/h |

| Certification | ISO9001 CE, ISO9001:14000 |

| Advantage | Timely Delivery and Installation, Fast Technical Support |

Product Detail

Small Scale Gold Extraction Recovery Washing Machine/Manganese Ore Wash Mining Equipment/Gold Processing Plant For Sale

Product Description

Small CIL CIP hard rock gold wash recovery / elution / extraction / refinery plant for sale

The gold beneficiation process is gravity separation, flotation, magnetic separation, cip, cil , heap leaching and other combined methods.

* Alluvial/Placer gold process: The gold concentrate of placer gold ore has a high content and mostly exists in the form of sand grains. Therefore, gravity separation is often used when sorting. After pretreatment, desliming and washing of ore, coarse gold ore particles can be directly obtained by gravity separation process.

* Rock gold process: The hard rock gold processing plant is very efficientwith a recovery rate of 95%, primarily by removing most of the individual crude gold ore through gravity separation process. Commonly used processes also flotation, CIL and CIP process.

* Associated gold ore process: depleted sulfide gold ore, polysulfide gold ore, gold-bearing polymetallic ore, telluride-bearing gold-gold ore, and gold-bearing copper ore. According to the nature of the ore, the application of multiple combined processes is often used to select the minerals separately.

Small Scale Gold Washing Plant Trommel Washing Plant Gold Separator for sale

Capacity: 50t/h sand gold processing plant

2-5kg gold per day You will get.

7 days you will recover the cost of machine.

Produced in China 20 days, sea transport to Africa 40-50 days.

2-5kg gold per day You will get.

7 days you will recover the cost of machine.

Produced in China 20 days, sea transport to Africa 40-50 days.

Main Steps of gold ore processing plant

Placer gold mines and rock gold mines are often mined.

Gold ore mines have 4 types: placer gold mine, carlin-type gold mine, volcanic gold mine, rock gold mine, and iron cap gold mine.

1. Crushing: Use jaw crusher to crush the raw material into 0-25mm particles.

2. Grinding: Use ball mill to grind the particle materials into powder (0.074-2mm).

3. Gravity concentration: Use gold shaking table to separate the gold concentrate from the powder(0-2mm).

Working Flow

Low Cost Small Gold Plant Flowchart

Gold ore processing plants are common including washing & screening, crushing & grinding, beneficiation, concentration, drying or smelting.

1. Washing & screening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation.

2. Crushing & grinding: The content of gold in the ore is extremely low. To extract gold, gold ore processing equipment crushes and grinds the ore and adopts ore dressing methods to pre-enrich or separate gold from the ore.

3. Beneficiation stage: According to the characteristics of various types of ores, one or more comprehensive separation processes of gravity separation, flotation, cyanidation, carbon slurry and adsorption are adopted.

4. Tailings processing: Generally, the concentration + filtration + dehydration process is mostly used. If required, suitable reprocessing can also be customized according to the nature of the tailings.

5. Smelting: After obtaining high-purity gold, it can be cast into gold nuggets, coins or other shaped products by melting furnace according to needs.

1. Washing & screening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation.

2. Crushing & grinding: The content of gold in the ore is extremely low. To extract gold, gold ore processing equipment crushes and grinds the ore and adopts ore dressing methods to pre-enrich or separate gold from the ore.

3. Beneficiation stage: According to the characteristics of various types of ores, one or more comprehensive separation processes of gravity separation, flotation, cyanidation, carbon slurry and adsorption are adopted.

4. Tailings processing: Generally, the concentration + filtration + dehydration process is mostly used. If required, suitable reprocessing can also be customized according to the nature of the tailings.

5. Smelting: After obtaining high-purity gold, it can be cast into gold nuggets, coins or other shaped products by melting furnace according to needs.

Why Choose Us

ZOOMJO has over 40 years of experience in all types of gold processing equipment, and our ability to combine craftsmanship and robust design makes us your one-stop solution for small-scale gold process plants. It supports customized gold processing plants and equipment, portable machine supplier, is not limited by the site and is easy to move.

Technical Parameter

Main equipment of ore beneficiation line

Equipment | Function |

Jaw crusher | Crush the material to below 300 mm for the first-stage crushing. |

Cone crusher | Crush the material to below 20 mm for the second-stage crushing. |

Ball mill | Crush and grind materials of 20 mm to 0.074-0.4 mm. |

Spiral classifier | According to the different specific gravity of the materials, the ore mixture is washed and classified. |

Magnetic separator | Magnetic material is separated from other materials by magnetic and mechanical forces. |

Flotation machine | Add reagents to separate the required minerals from other substances. |

High-efficiency concentrator | Concentrate the pulp. |

River sand dryer | Dry the material. |

We can customize according to your needs

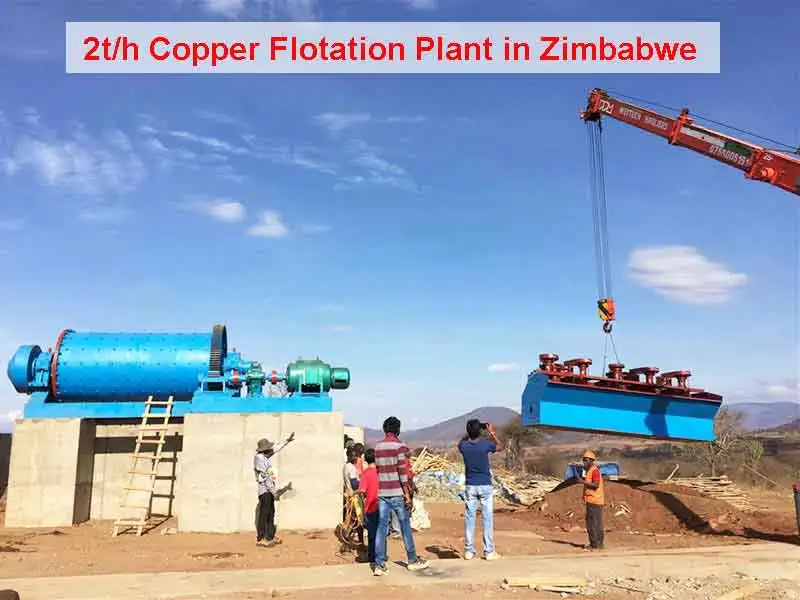

Delivery Site

Packaging & Shipping

Packaging Details: We will make different packaging according to different machine sizes. Standard international export packing, container, wooden box.

Delivery Time: We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Customer Cases

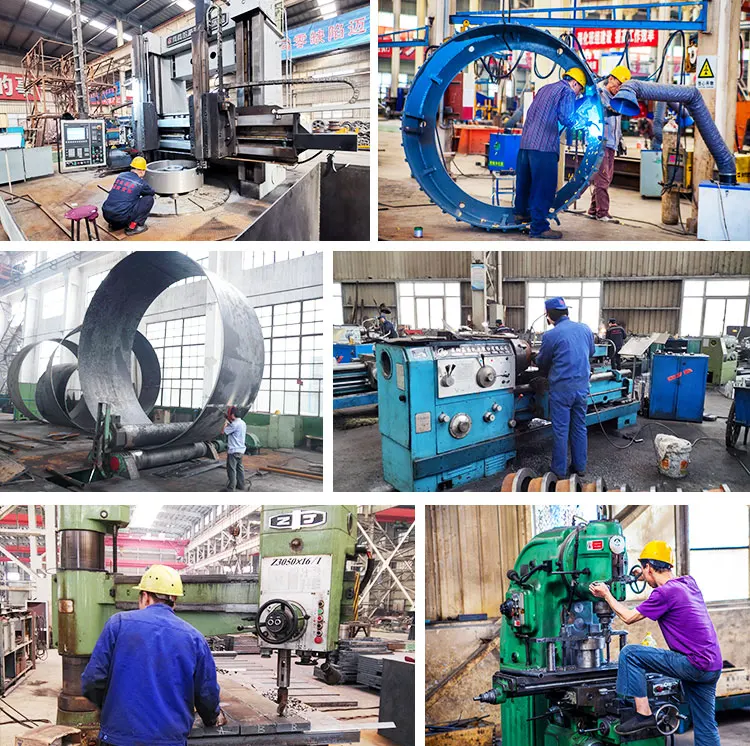

Company Profile

ZOOMJO is a large-scale enterprise that mainly produces heavy mining machinery and integrates scientific research, production and sales. It mainly produces various large and medium-sized crushing equipment, sand making equipment, drying and calcining equipment, mineral processing equipment and other series of products.

ZOOMJO has developed steadily from its establishment to the present with its technical strength, and has grown stronger day by day, and has gathered a large number of high-level management and scientific research personnel. Our company covers an area of 50,000 square meters, and another 10,000 square meters of modern office space, R&D center and sales center. The company has more than 500 employees, including more than 20 intermediate technicians. With strong technical strength, scientific management system and high product quality, ZOOMJO will rapidly grow into an important production and export base of mining machinery.

FAQ

1. How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2. Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

3. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food.

4. Service and Payment Terms?

a. We usually accept T/T, L/C, but other terms also workable.

b. We take pictures of finished products before delivery.

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2. Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

3. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food.

4. Service and Payment Terms?

a. We usually accept T/T, L/C, but other terms also workable.

b. We take pictures of finished products before delivery.