cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

cut to length machine

Types of Cut to Length Machines

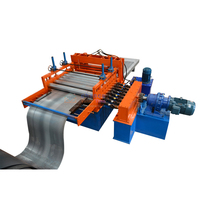

A cut to length machine is a device that cuts and severs materials to predetermined lengths. The material is usually unrolled before cutting and is commonly used in the metal processing industry. Materials of various thicknesses and widths, including steel plates, strips, pipes, and sheets, can be handled by the cut-to-length device. The ability to control the length and quantity of cuts precisely is a defining feature of cut-to-length machines.

Cut-to-length machines make high-precision cuts on materials such as steel plates, metal sheets, aluminum plates, and stainless sheets. Using an electric, air-powered, hydraulic, or manual lever mechanism, the machine provides faster, more efficient, and safer cutting and seaming than traditional methods. Most machines have a feed mechanism to advance the material, a cutting mechanism to sever it, and a stopping mechanism to control the length accurately. Advanced machines may also have a flattening mechanism to level the material before cutting, a part that allows for better handling and processing of materials with varying thicknesses and flatness characteristics.

Basic cut-to-length machines include shear cutters and roll-fed shear cutters. Advanced machines with the same or similar functionalities include nesting cutters, which cut patterns while optimizing material use, programmable cutters with CNC control for high-precision cuts according to specified programs, automated feeders that allow for continuous feeding of material and cutting without manual intervention, and combined machines that can cut to length and shape simultaneously. Other specialized machines include contour cutting machines for cutting irregular shapes or curves and waterjet cutting machines that use high-pressure water and abrasive mixtures for cutting.

Basic and advanced cut-to-length machines can also be categorized into mechanical cutting and non-contact cutting based on how they cut the material. Mechanical cutting refers to devices that cut material directly, such as shearing machines, while non-contact cutting refers to devices that cut using laser technology.

Specifications and Maintenance of Cut to Length Machines

Cut to length lines are available in different specifications to suit various industrial applications. The following are the key specifications corresponding with their respective maintenance requirements.

-

Thickness Range

Cut to length machines can operate on sheet metal of various gauges or thicknesses. Heavier gauge metals require higher cutting force and may need more significant, sturdier blades and machines. The blade's sharpness must be maintained as per the thickness of the sheet metal being worked on. For example, a machine handling light-gauge metals will need to have its blades sharpened or replaced less frequently than a heavy-gauge machine.

-

Width Range

Machines handling wider sheet metal will have to process more extensive, heavier coils. Such machines may need a more considerable cutting capacity and additional support for the material being cut. The operator must ensure that all the parts used to handle the metal are fully supported and working fine. More extensive widths will add to the machine's workload and may require more frequent lubrication, cleaning, and a shorter blade sharpening interval.

-

Length Range

Some machines also have to cut very long pieces before feeding the material to rolling or other processes. These machines will usually have large motors that draw more power. Such machines will have to handle a longer workload, increasing the cutting's friction and surface area. More extended workload may lead to higher heating, requiring more frequent cooling and lubrication of moving parts.

-

Capacity

A cut-to-length machine's capacity regarding metal coil weight is critical to consider. Larger capacities will handle more tremendous pressures and weights, leading to higher wear and tear. Operators must calculate load-bearing capacities to ensure that they can cut coils efficiently. Higher capacities may require extra responsibilities for machines, such as cooling and lubrication systems.

Application Scenarios

Acutallength cutting machine is used in many Industries where metal or other material of precise length is required. The following are some of the application scenarios where the cut to length line is used:

-

Construction / Fabrication Industry

In construction and metal fabrication cuts to length machines are used to cut pipes, beams, and other metal for building structures, frames, and support systems. The cut to length ensures that construction materials are of the required length and fit together properly.

-

Automotive Industry

In the automotive industry, the cut to length helps to manufacture automotive components, such as chassis parts, body panels, and exhaust systems. It ensures that the components meet the required specifications and tolerances.

-

Plastics Industry

In the plastics industry, the cut to length devices help to cut plastic sheets, films, and tubes. It allows for precise length control and reduces waste.

-

Packaging Industry

In the packaging industry, the cut to length machines are used to cut packaging materials, such as labels, stickers, and shrink sleeves. It ensures that the packaging materials are of the required size and fit.

-

Textile Industry

In the textile industry, the cut to length devices help to cut fabric rolls, tapes, and webbing. It allows for precise length control and improves production efficiency.

-

Aerospace Industry

In Aerospace manufacturing, the cut to length devices are used to cut metal, and composite materials to produce aerospace components, such as frames wings, and fuselage sections. It ensures that the materials are of the required length and quality.

-

electronics industry

In the electronics industry, the cut to length devices are used to cut wires, cables, and printed circuit board (PCB) materials. It ensures that the electronic components are of the required size and specifications.

-

Marine Industry

In the marine industry, the cut to length devices are used to produce marine components, such as hull sections, deck plates, and piping systems. It ensures that the marine materials are of the required length and fit for assembly.

-

Woodworking Industry

In the woodworking industry, the cut to length device helps cut wooden boards, panels, and planks. It ensures that the woodworking materials are of the required size and quality for furniture and construction projects.

-

glass industry

In the glass processing industry, cut to length devices are used to cut glass sheets, panels, and blocks. It ensures that the glass materials are of the required length and fit for architectural and decorative applications.

How to choose Cut to Length Machines

Selecting the right cut-to-length lines can be made simple by considering a few crucial elements. First, knowing the kind of material the machine will work with is really important. This includes the thickness and width of the material. Second, businesses should think about the capacity and speed they need. The machine's speed can affect how quickly production is done, so it's essential to choose a cut-to-length machine that matches the required pace. Third, the cutting precision of the machine is vital. It should be accurate enough to make cuts within acceptable tolerances to ensure product quality. Fourth, buyers should consider the machine's flexibility. Some machines can handle various materials and sizes, which can be very helpful.

Also, the ease of use and safety features of the machine are important to consider. Is it easy to operate, and does it have safety measures to protect workers? Additionally, businesses should think about the maintenance needs of the machine in order to keep it running well over time. Finally, it's wise to research the supplier's reputation and the after-sales support they offer, including maintenance and spare parts support. By keeping all these factors in mind, buyers can choose the cut-to-length machine that best meets their needs and helps their production process run smoothly.

Cut to length machine FAQ

Q1: How does an automated cut-to-length machine work?

A1: An automated cut-to-length machine works by uncoiling material, straightening it, cutting it to desired lengths, and then stacking or piling the cut parts. It can do all these processes automatically.

Q2: What kind of materials can a cut-to-length machine process?

A2: A cut-to-length machine can process various materials like metal, plastic, wood, glass, and composite materials. The specific capability depends on the design and features of the machine.

Q3: Can a cut-to-length machine handle irregularly shaped materials?

A3: Yes, some advanced cut-to-length machines can process irregularly shaped materials, but that mainly depends on the machine's design and specifications. Only machines with special attachments or custom configurations can do that.

Q4: What's the difference between a cut-to-length machine and a saw?

A4: A cut-to-length machine is industrial equipment used to cut materials to specific lengths, often continuously. In contrast, a saw is a hand tool or machine used for cutting various materials, usually in a more flexible and less controlled manner.